Metallographic corrosion method for martensitic precipitation hardening stainless steel crystal boundary

A technology of precipitation hardening and metallographic corrosion, which is applied in the field of metallographic inspection of metal materials, can solve the problem that there is no suitable corrosion method for the grain boundary of martensitic precipitation hardening stainless steel, and achieve the effect of good grain boundary display and short corrosion time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1) Add 2m concentrated hydrochloric acid with a mass concentration of 36.5% to 30ml of concentrated nitric acid with a mass concentration of 69%, stir evenly and let it stand for 10 minutes before use.

[0022] 2) Wipe the polished surface with absorbent cotton dipped in the prepared etchant for 20 seconds, and the surface of the sample is observed to be gray in color.

[0023] 3) Rinse the sample with running water, rinse the sample with absolute ethanol, dry it with a hair dryer and observe it.

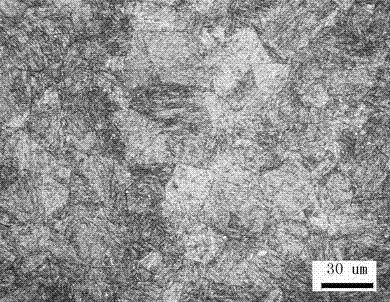

[0024] 4) Take pictures of the grain size. If you take a good picture, you can properly adjust the brightness and contrast of the picture. The purpose is to make the grain boundary darker, the contrast stronger, and the structure tend to be white and bright, so as to highlight the grain boundary morphology. The photo of its grain size is shown in image 3 .

[0025] visible, image 3 The medium grain boundary is clear and complete, and the color and shape of the structure ...

Embodiment 2

[0027] 1) Add 3ml of concentrated hydrochloric acid with a mass concentration of 36.5% to 30ml of concentrated nitric acid with a mass concentration of 69%, stir evenly and let it stand for 10 minutes before use.

[0028] 2) Wipe the polished surface with absorbent cotton dipped in the prepared etchant for 15 seconds, and the surface of the sample is observed to be gray in color.

[0029] 3) Rinse the sample with running water, rinse the sample with absolute ethanol, dry it with a hair dryer and observe it.

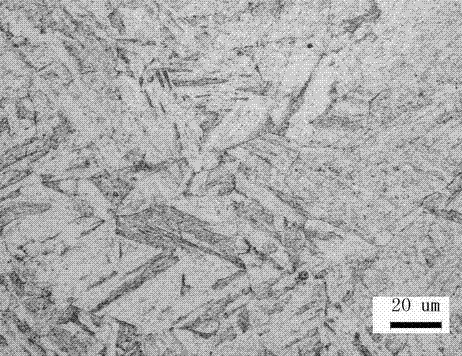

[0030] 4) Take pictures of the grain size. If you take a good picture, you can properly adjust the brightness and contrast of the picture. The purpose is to make the grain boundary darker, the contrast stronger, and the structure tend to be white and bright, so as to highlight the grain boundary morphology. The photo of its grain size is shown in Figure 4 .

[0031] visible, Figure 4 The medium grain boundary is clear and complete, and the color and shape of the stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com