Analytic pretreatment machine for metal material and treatment method for analytic pretreatment machine

A technology of metal materials and flanges, which is applied in the field of metallurgical analysis and detection, can solve the problems of secondary oxidation, low degree of automation, and influence on analysis results, and achieve the effect of avoiding secondary oxidation, satisfying rapid analysis, and accurate detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

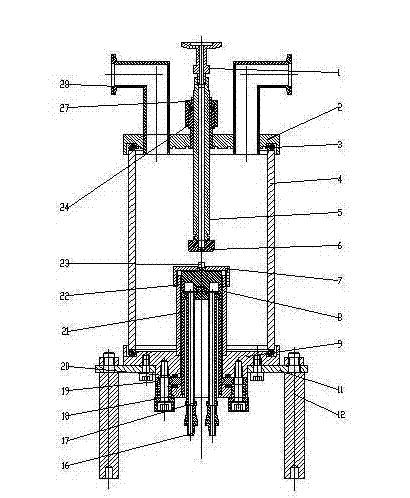

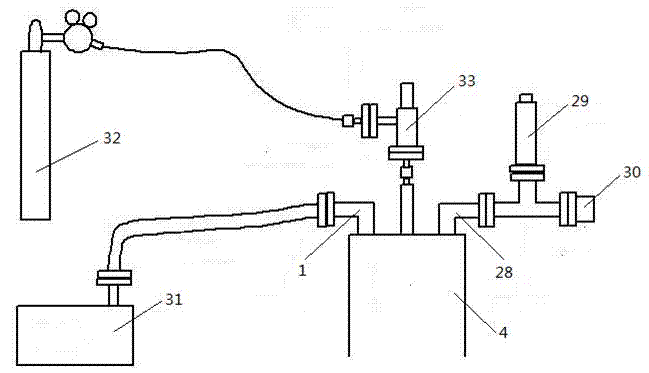

[0019] The metal material analysis preprocessing machine of the present embodiment is as figure 1 As shown, the vertical cylindrical vacuum chamber is composed of a lower flange 9 and an upper flange 2 with opposite ring grooves on the upper and lower surfaces, and a glass cylinder 4 whose inner and outer diameters match the ring grooves. , The lower ends are respectively inserted into the ring grooves of the upper and lower flanges lined with sealing rings 3, and the sealing is firmly connected. One side of the cylinder body 4 has a sealed door (not shown in the figure), and the top flange of the vacuum chamber has an air extraction port 1 and a flange joint 28 for measuring the vacuum degree.

[0020] The bottom of the vacuum chamber is supported on the foot bar 12 through the bottom plate 11 . The bottom surface of the lower flange 9 of the vacuum chamber is insulated and fixedly connected to the cathode flange 18 connected to the high-voltage power supply through the seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com