Circular immersion-cleaning method for carpet printing and immersion-cleaning equipment

A carpet and printing technology, applied in the direction of dyeing, dry cleaning fiber products, textiles and papermaking, etc., can solve the problems of large environmental pollution, increased workload, and increased production costs, so as to reduce production costs, improve work efficiency, and improve utilization. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0028] Example.

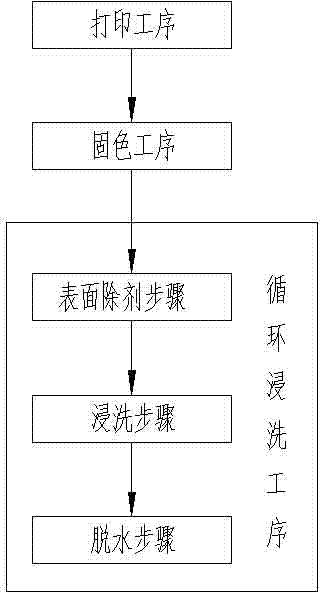

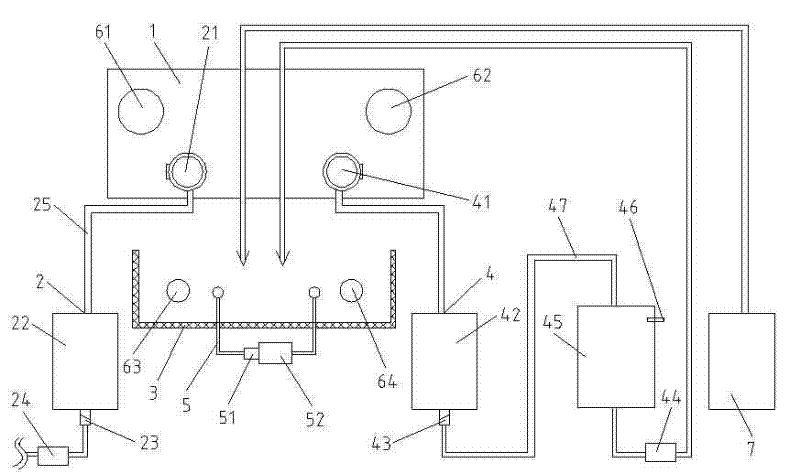

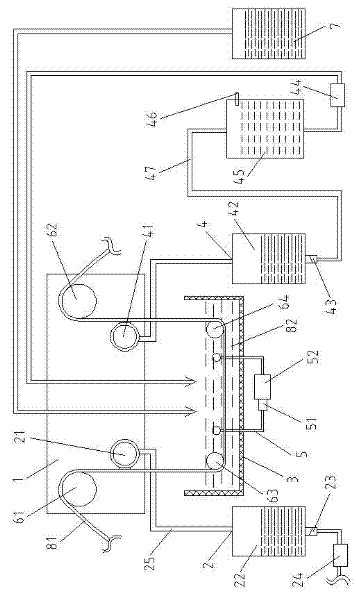

[0029] see Figure 1 to Figure 3 , the carpet printing cyclic immersion method in the present embodiment comprises a printing process, a color fixing process and a cyclic immersion process in sequence, wherein, in the printing process, the color paste is printed onto the suede surface of the carpet 81, thereby the required pattern Print onto carpet 81. The color paste used for printing includes dyes and thickeners. Usually, the thickener accounts for 60%-70% of the total weight of the color paste. In the printing process, the viscosity of the thickener is usually around 300cps, and the color of the dye can be It is formulated according to the pattern printed on the carpet 81 as desired. After th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com