Method for inhibiting grid emission of pulsed travelling wave tube

A technology for suppressing pulses and traveling wave tubes, applied in traveling wave tubes, electronic tubes with speed/density modulation electron flow, etc., can solve problems such as traveling wave tube failure, transmitter ignition failure, modulator ignition, etc., to achieve Guarantee reliability and stability, long service life, eliminate the effect of grid emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

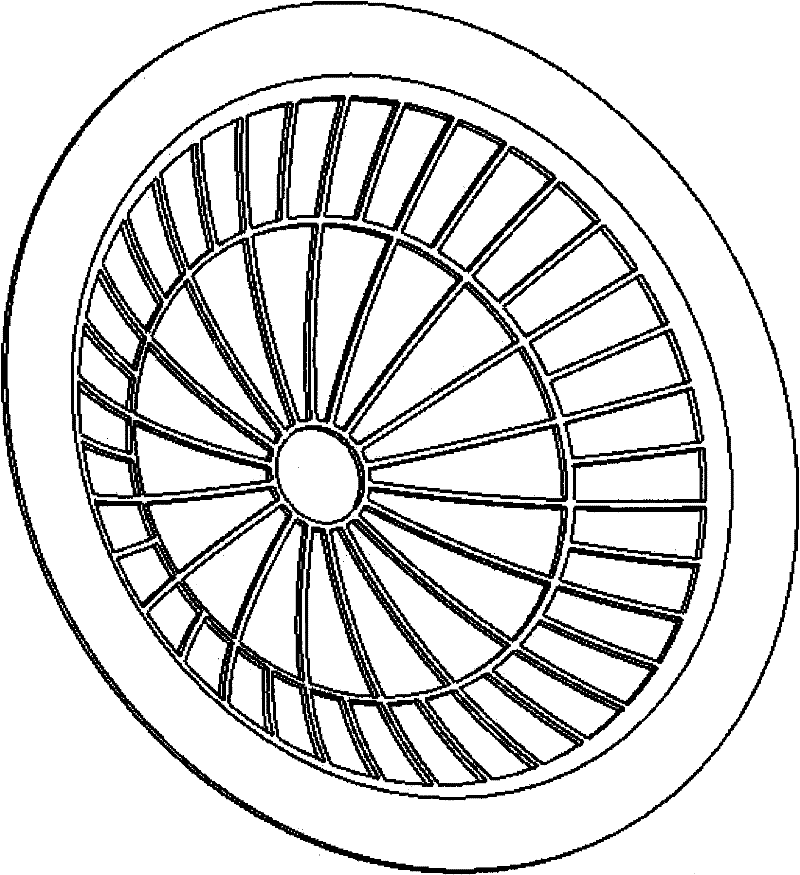

[0023] A method for suppressing grid emission of a pulse traveling wave tube of the present invention directly uses hafnium (Hf) as grid material. Hafnium is also a high-temperature electric vacuum material, but its plastic processing performance is worse than that of molybdenum. However, after strictly controlling the annealing process and a series of process operation procedures, the yield of finished products can be effectively improved. In addition, it needs to be emphasized that due to the fact that hafnium can combine with H at a certain temperature 2 , O 2 , N 2 Therefore, it is necessary to pay attention to the ambient atmosphere at high temperature, so as to avoid the change of the material form of hafnium in a certain high temperature and certain atmosphere, resulting in a significant decrease in the mechanical strength of the grid.

[0024] A method for suppressing the grid emission of a pulsed traveling wave tube of the present invention, particularly relates to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com