Component structure for detecting filling ability of pre-metal dielectric

A technology of pre-metal dielectric and device structure, applied in the direction of electric solid-state devices, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problems of sample production failure and waste, and achieve convenient and efficient detection, convenient production, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

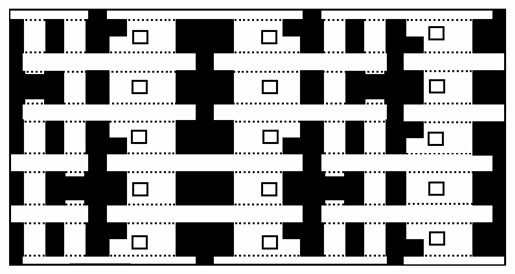

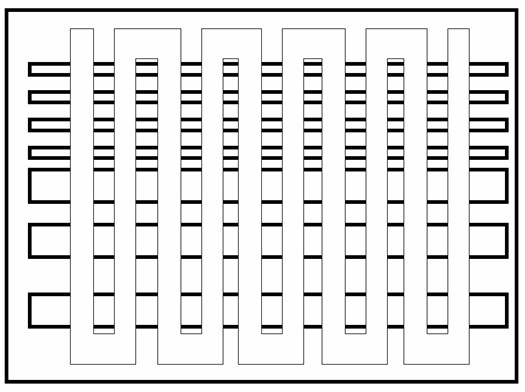

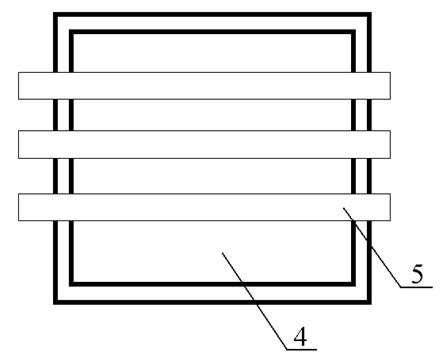

[0023] Such as Figures 3 to 5 As shown in the cross-section of the device structure used to detect the filling ability of the pre-metal dielectric of the present invention includes a plate figure 1 , 2 and 3.

[0024] Such as image 3 As shown in the version of the embodiment of the present invention figure 1 Composed of substrate 4 and gate 5, the plate formed in this way figure 1 The active area density is 100%;

[0025] Such as Figure 4 As shown in the version of the embodiment of the present invention figure 2 STI structure 6 is formed on the substrate 4, version figure 2 The gate 5 on the top is perpendicular to the STI6. another example Figure 4 As shown in the plate formed in this example figure 2 The active area density is 50%;

[0026] Such as Figure 5 As shown in the version of the embodiment of the present invention image 3 Composed of STI6 and gate 5, the plate formed in this way image 3 The active area density is 0%.

[0027] The cross-sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com