DIP (dual in-line package) component electrostatic protector

A technology of double in-line insertion and components, applied in the direction of electrical components, electric solid devices, semiconductor devices, etc., can solve problems such as component failure, and achieve convenient storage and good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

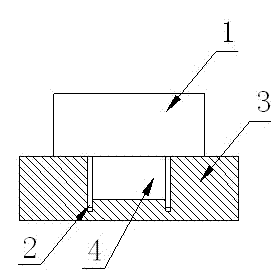

[0013] The content of the present invention will be described below in conjunction with specific embodiments.

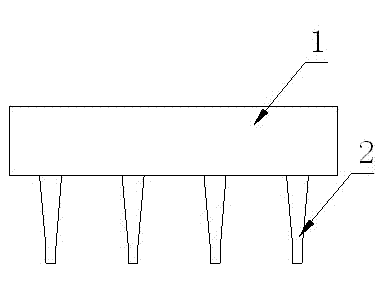

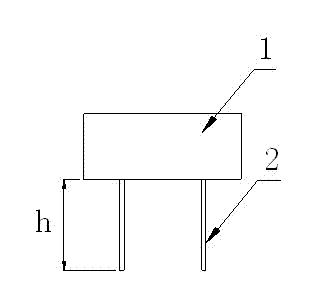

[0014] like figure 1 As shown, it is the front view of the dual-in-line component described in the present invention, figure 2 for its left view. The dual in-line component of the present invention includes a body 1 and lead pins 2 . The lead pins 2 are double rows, symmetrically distributed on one side of the body 1 . The lead pins 2 are fixed on the body 1, and the body 1 uses the lead pins 2 to contact the printed circuit board, and then access the circuit to work.

[0015] Since field effect components are prone to static electricity during packaging, transportation or operation, and field effect components have high input impedance, it is difficult to release the static electricity generated by the induced electric field and friction. It is easy to cause circuit breakdown in the main body 1, which directly affects the utilization rate of field effect compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com