Thin film solar battery and manufacturing method thereof

A technology of solar cells and manufacturing methods, which is applied to circuits, photovoltaic power generation, electrical components, etc., can solve the problems of reducing the bandgap width of thin-film solar cells, reducing the photoelectric conversion efficiency of thin-film solar cells, and polluting single-crystal silicon substrates, etc., to achieve Improve photoelectric conversion efficiency, reduce pollution, and increase the effect of bandgap width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

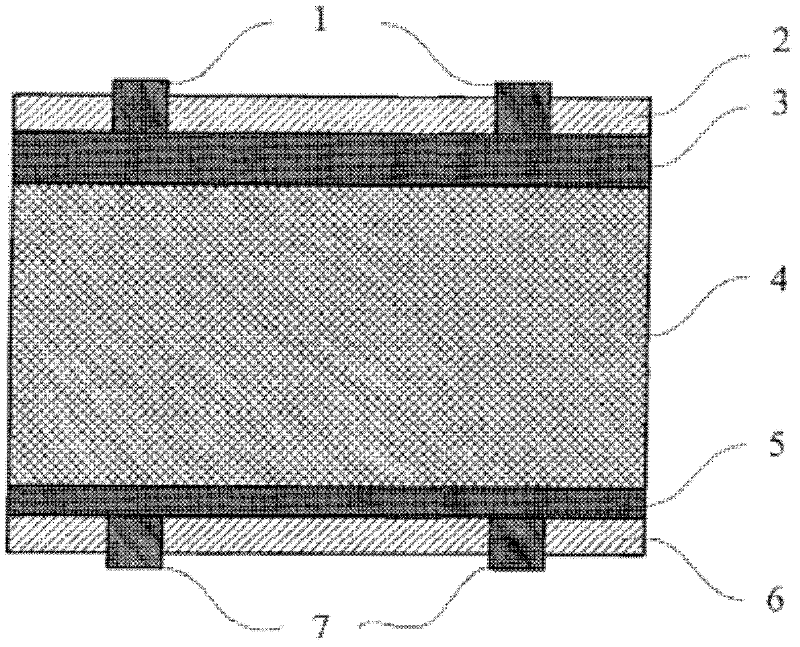

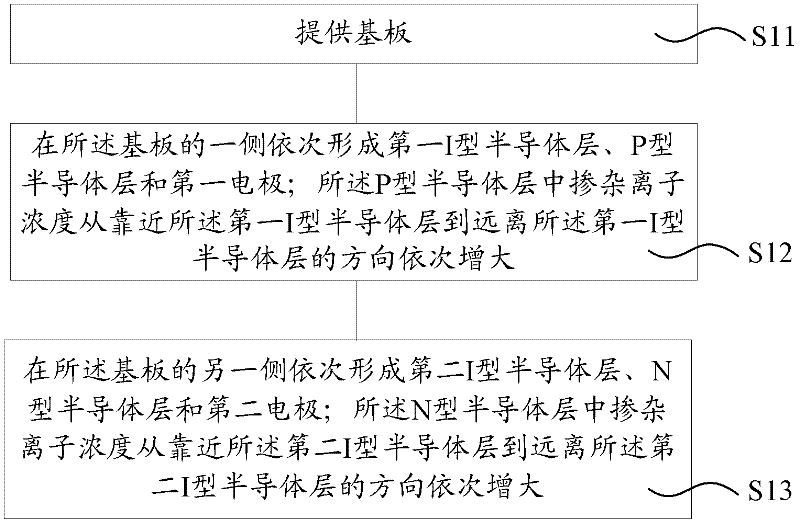

[0068] refer to figure 2 As shown, the present embodiment provides a method for manufacturing a thin-film solar cell, including:

[0069] Step S11, providing a substrate;

[0070] Step S12, sequentially forming a first I-type semiconductor layer, a P-type semiconductor layer, and a first electrode on one side of the substrate; the concentration of dopant ions in the P-type semiconductor layer ranges from close to the first I-type semiconductor layer to The direction away from the first I-type semiconductor layer increases sequentially;

[0071] Step S13, forming a second I-type semiconductor layer, an N-type semiconductor layer and a second electrode in sequence on the other side of the substrate; the concentration of dopant ions in the N-type semiconductor layer is from close to the second I-type semiconductor layer The direction away from the second I-type semiconductor layer increases sequentially.

[0072] In this embodiment, the pollution of the P-type semiconductor l...

Embodiment 2

[0124] This embodiment provides a method for manufacturing a thin-film solar cell, including:

[0125] Provide the substrate;

[0126] An I-type semiconductor layer and a P-type semiconductor layer are sequentially formed on the substrate, and the concentration of dopant ions in the P-type semiconductor layer increases sequentially from a direction close to the I-type semiconductor layer to a direction away from the I-type semiconductor layer.

[0127] Wherein, the substrate may be an N-type substrate.

[0128] The steps of forming the I-type semiconductor layer and the P-type semiconductor layer are the same as the steps of forming the first I-type semiconductor layer and the P-type semiconductor layer in Embodiment 1, and will not be repeated here.

[0129] After the P-type semiconductor layer is formed, an anti-reflection layer and a front electrode can be sequentially formed on the P-type semiconductor layer, and a back electrode can be formed on the lower surface of the ...

Embodiment 3

[0138] This embodiment provides a method for manufacturing a thin-film solar cell. The difference between it and Embodiment 2 is that in this embodiment, an N-type semiconductor layer is formed on the P-type semiconductor layer after the P-type semiconductor layer is formed.

[0139] Wherein, the concentration of dopant ions in the N-type semiconductor layer may be distributed uniformly or unevenly, which does not limit the protection scope of the present invention.

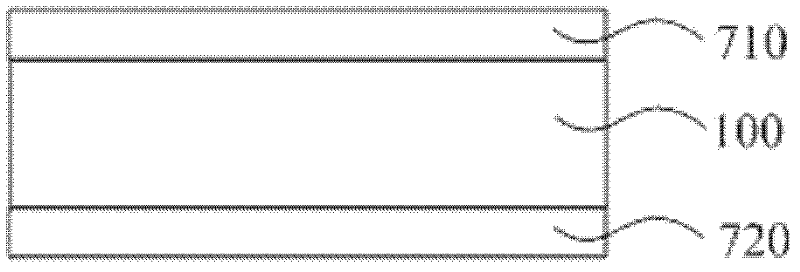

[0140] Specifically, refer to Figure 13 As shown, the thin-film solar film cell made by the method of this embodiment includes:

[0141] Substrate 30;

[0142] I-type semiconductor layer 31, P-type semiconductor layer 32, N-type semiconductor layer 33, anti-reflection layer 34 and front electrode 35 located on the upper surface of the substrate 30 in sequence;

[0143] The back electrode 36 located on the lower surface of the substrate 20 .

[0144] Wherein, the substrate 30 may be an N-type substrate or a P-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com