Microorganism concentration process and device

A microbial concentration technology, applied in the field of microbial concentration and devices, can solve the problems of expensive, slow diagnostic application, etc., and achieve the effect of eliminating sample processing, simple cost and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

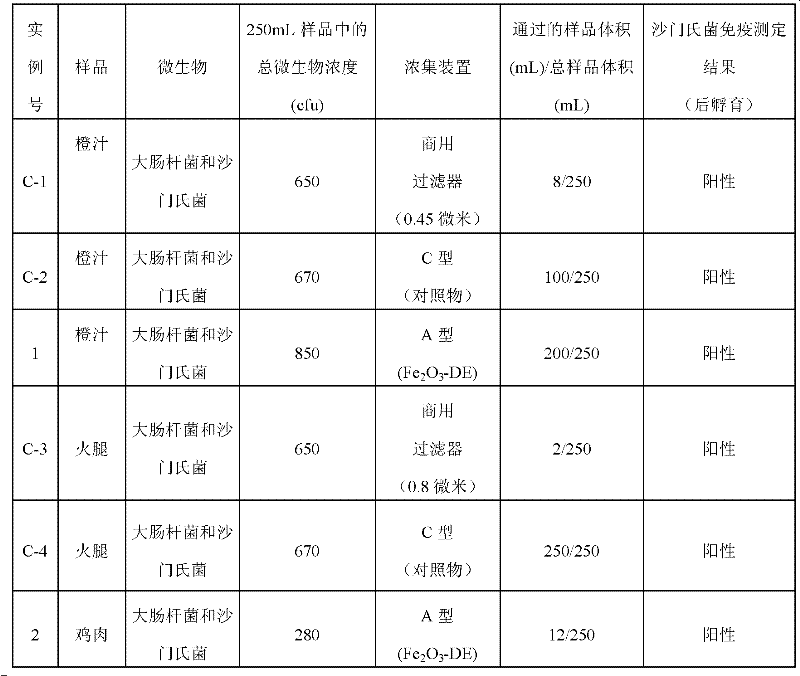

example 1-2 and comparative example C-1-C-4

[0197] Food samples (pasteurized orange juice (without pulp), sliced ham luncheon meat, and sliced chicken luncheon meat) were purchased from a local grocery store (Cub Foods (St. Paul, MN)). Separately in sterile Stomacher TM 25 mL of orange juice and 25 grams of each sliced meat were weighed into polyethylene filter bags (PE-LD Model 400, Seward Corp (Norfolk, UK)). The resulting samples were each obtained from an overnight tryptic soy broth culture (essentially as described above based on the title "Concentration Agent Screening: Microorganism Concentration Test Method"). prepared as described, except using Bacto TM Tryptic Soy Broth (Becton Dickinson (Sparks, MD)) was inoculated with Salmonella enterica subsp. Typhimurium (ATCC 35987) and E. coli bacteria (ATCC 51813) at a concentration of about 1 CFU / mL.

[0198] After inoculating the inoculated samples for about 10 minutes at room temperature (about 23°C), test samples were prepared by adding 225 mL of sterile B...

example 3

[0205] Pasteurized apple juice was purchased from a local grocery store (Cub Foods (St. Paul, MN)). 25 mL of apple juice was mixed with 225 mL of sterile Butterfield's Buffer (pH 7.2, VWR (West Chester, PA)) and inoculated with Salmonella enterica subsp. Typhimurium (ATCC 35987) at a concentration of about 100 CFU / mL. The resulting samples were incubated at room temperature (about 23°C) for 10 minutes and then pumped (essentially as described above) through type B (TiO) at a flow rate of 10 mL / min. 2 -DE) concentration device (prepared essentially as above) for 25 minutes. Flow-through sample fractions (1 mL) were collected in labeled sterile 5 mL polypropylene tubes (BD Falcon) every 5 minutes for 25 minutes. TM , Becton Dickinson (Franklin Lakes, NJ)) and plated at 3M according to the manufacturer's instructions TM Petrifilm TM Aerobic Count Plates Medium (dry, rehydratable; 3M Company (St. Paul, MN)).

[0206] After the sample passed through the concentration device, ...

example 4

[0214] 5 mL of BBL was inoculated with an isolated bacterial colony of Salmonella enterica subsp. typhimurium (ATCC 35987) TM Trypticase TM Soy Broth (BBL TM Trypticase TM Soybean Broth) (Becton Dickinson (Sparks, MD)) and incubated at 37°C for 18-20 hours. Set the concentration to about 1 x 10 9 CFU / mL of this overnight culture was diluted in Butterfield's Buffer (pH 7.2 ± 0.2; potassium dihydrogen phosphate buffer; VWR cat. no. 83008-093, VWR (West Chester, PA)) to obtain approximately 1 x 10 3 CFU / mL of inoculum.

[0215] Use about 1×10 3 A 1:100 dilution of the inoculum in CFU / mL inoculates a 250 mL volume of drinking water (from a drinking water sprinkler), yielding a sample concentration of about 16 CFU / mL (about 4000 CFU total in the 250 mL sample). The sample was pumped (essentially as described above) through Type A (Fe) at a flow rate of 10 mL / min. 2 O 3 -DE) concentration device (prepared essentially as above) for 25 minutes. Flow-through sample fraction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap