Twin-shaft pitch electric bolt screwing machine

A tightening machine and electric technology, which is applied in the direction of engines, wind engines, machines/engines, etc., can solve problems such as uneven torque, deformation of the pitch meter, waste of labor costs, etc., and achieve the requirements of ensuring installation accuracy, balanced pressing force, The effect of high tightening accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

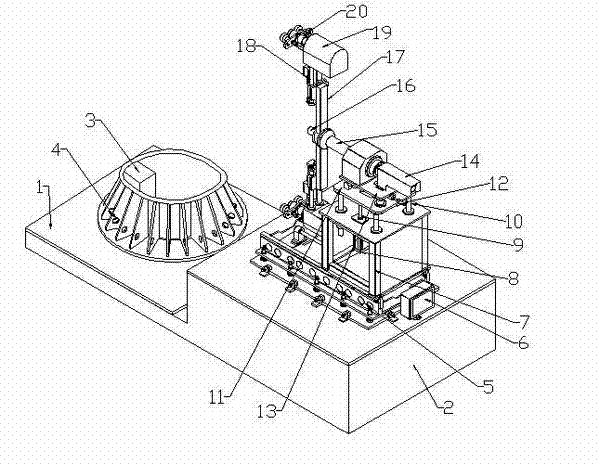

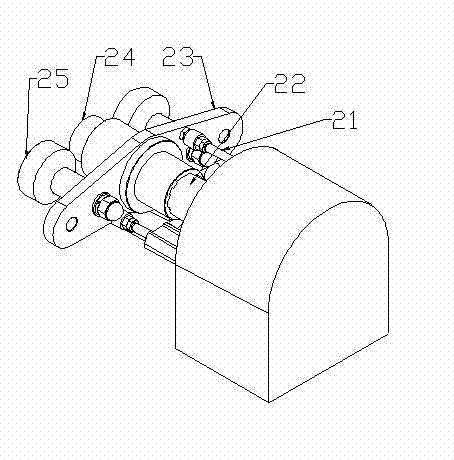

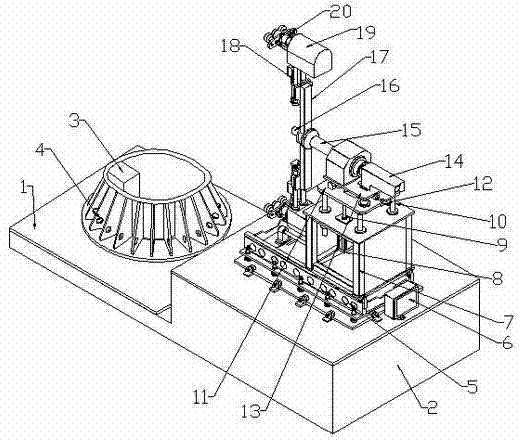

[0017] figure 1 , figure 2 The reference signs shown are as follows: the front end of the base body 1, the rear end of the base body 2, the servo motor 3, the servo rotary table 4, the servo feed slide table 5, the pneumatic device 6, the base of the main machine 7, the elevator 8, and the lifting adjustment guide column 9 , support column 10, lifting platform 11, angle adjuster 12, bearing platform 13, rotary servo motor 14, output shaft 15, centering device 16, rotating arm 17, sliding screw 18, tightening servo motor 19, automatic cap recognition and Reaction force device 20, feed screw 21, tightening shaft 22, reaction force support plate 23, special sleeve 24, reaction force cover 25.

[0018] figure 1 , figure 2 In the schematic diagram of the two-axis variable pitch electric bolt tightening machine shown, it mainly includes: the front end of the base body 1, the rear end of the base body 2, the servo motor 3, the servo rotary table 4, the servo feed slide table 5, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com