Conveying device and system

A technology of conveying device and driving device, which is applied to conveyor objects, transportation and packaging, furnaces, etc., to achieve the effects of long service life, simple logic control optimization, and easy and precise control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the embodiments provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

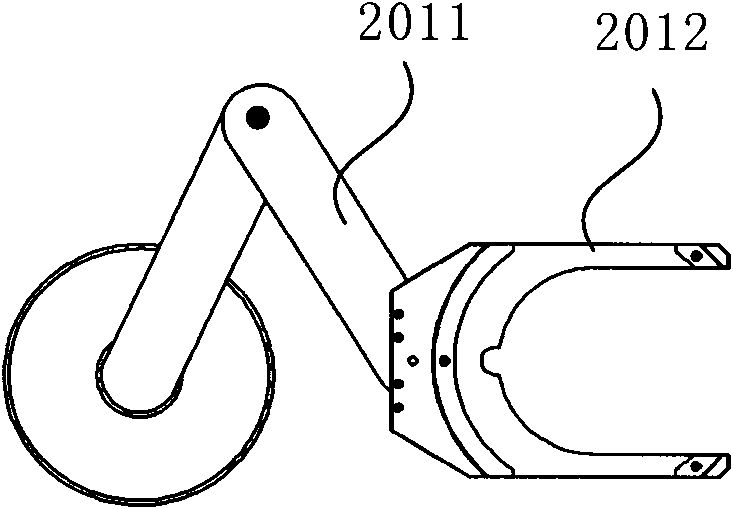

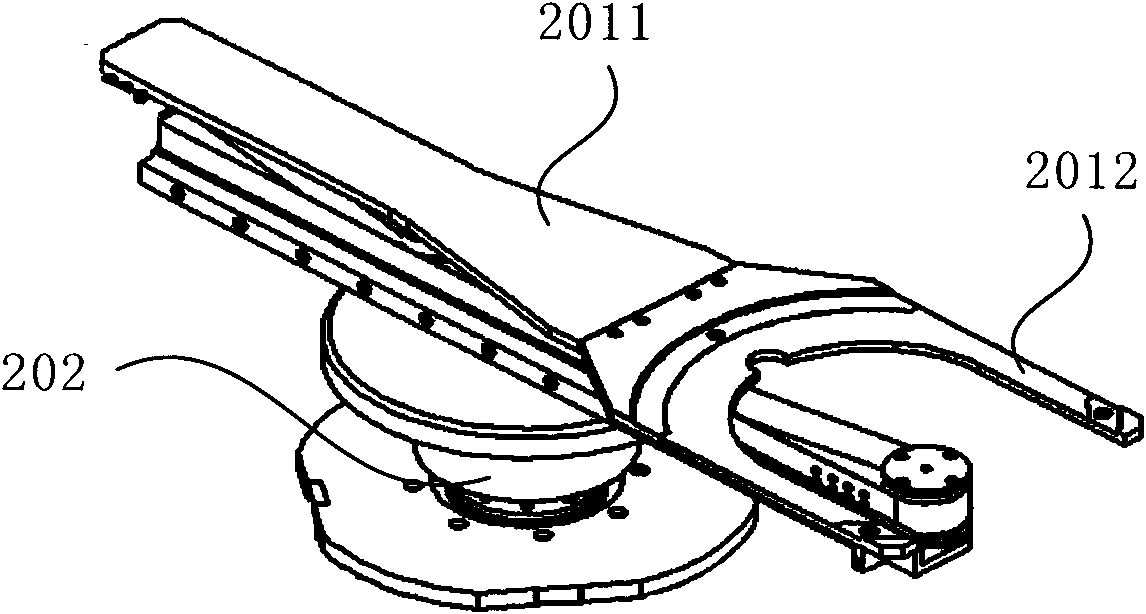

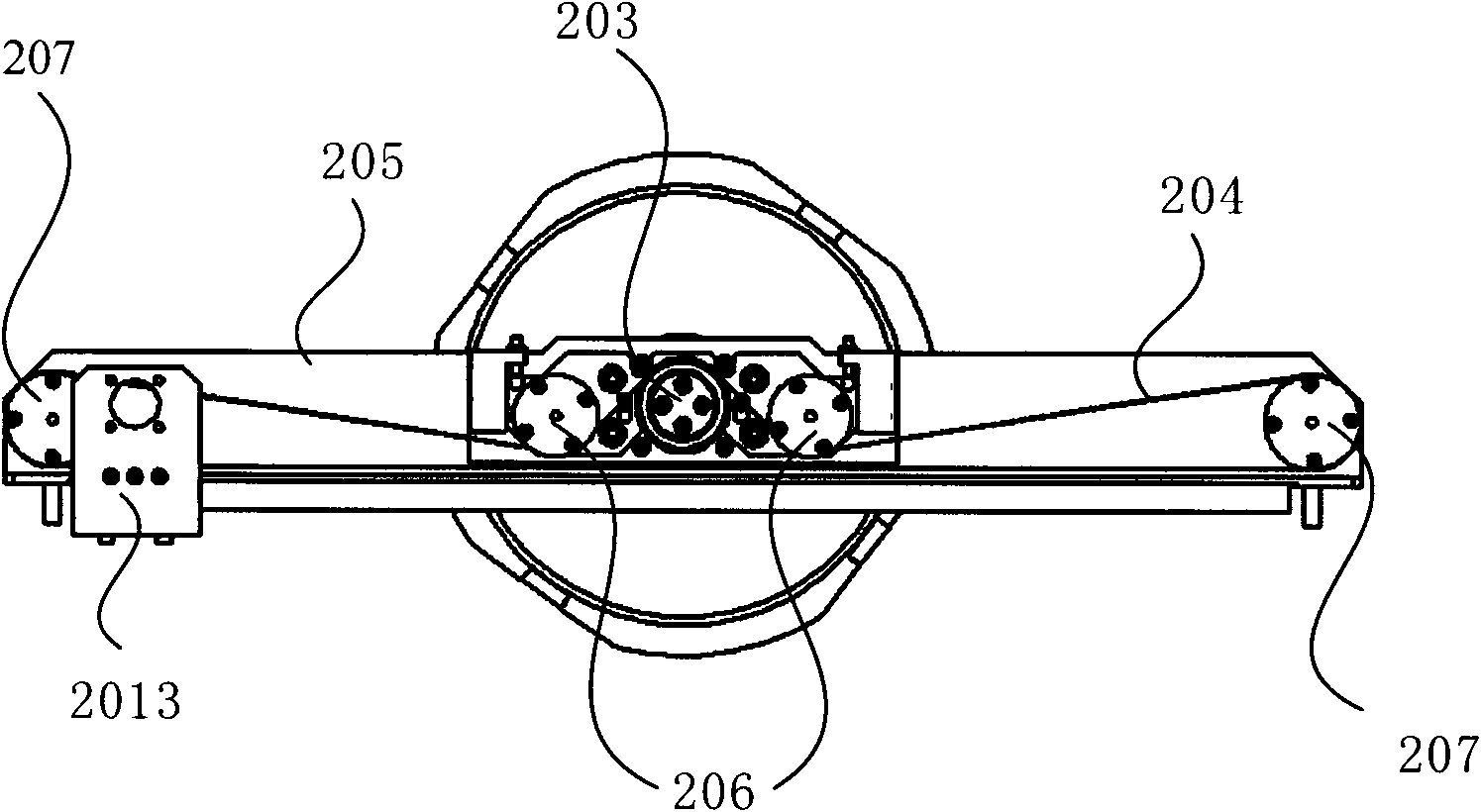

[0028] figure 2 It is a perspective view of the first embodiment of the conveying device provided by the present invention, image 3 It is a top view of the first embodiment of the conveying device provided by the present invention, Figure 4 It is a schematic structural diagram of the bracket in the first embodiment of the delivery device provided by the present invention. combine figure 2 , image 3 with Figure 4 As shown, the transmission device in this embodiment includes: a mechanical arm, a first driving device 202, a friction wheel ( figure 2 not shown in ) and a rotating belt 204, wherein the mechanical arm includes a fixedly connected extension piece 2011, a support piece 2012 and a support piece 2013, one en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com