A photocatalytic hydrogen production system, a method for preparing polycarbonyl diiron disulfide cluster compounds, and a method for preparing hydrogen

A technology of polycarbonyl diiron disulfide clusters and photocatalysis, applied in the direction of iron organic compounds, organic compounds/hydrides/coordination complex catalysts, chemical instruments and methods, etc., can solve system deactivation, loss of catalytic activity, Catalyst instability and other problems to achieve high stability and high hydrogen production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

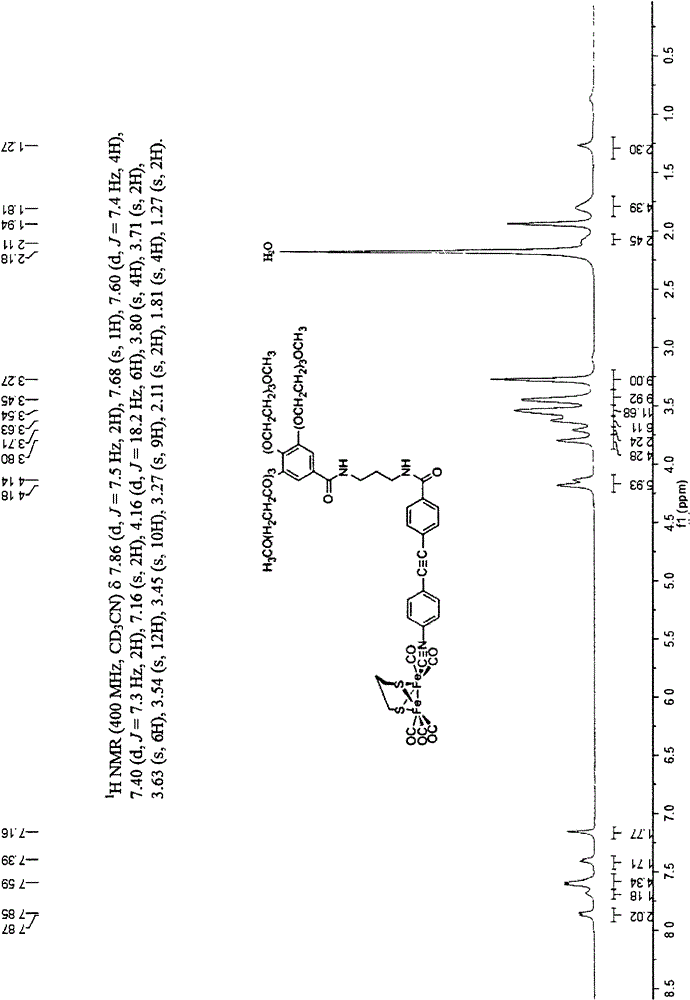

Embodiment 1

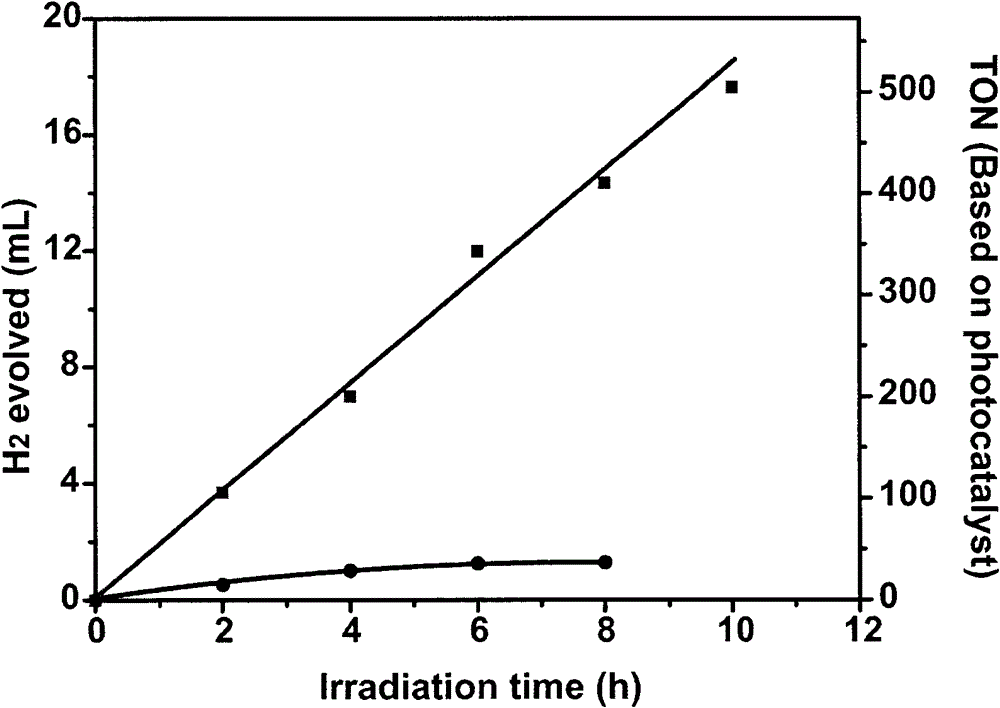

[0046] A photocatalytic hydrogen production system containing polycarbonyl diiron disulfide cluster compounds: the concentration of water-soluble polycarbonyl diiron disulfide cluster compounds is 1.56×10 -4 M; the concentration of CdTe quantum dots (abbreviated as: MPA-CdTeQDs) with mercaptopropionic acid as a stabilizer (in terms of Cd 2+ Meter) is 1.00×10 -3 M; ascorbic acid (H 2 A) The concentration is 8.52×10 -2 M; the size of MPA-CdTe QDs is 3.4nm; the solvent is water; the total sample volume is 10ml; the pH of the sample before light is 4.0.

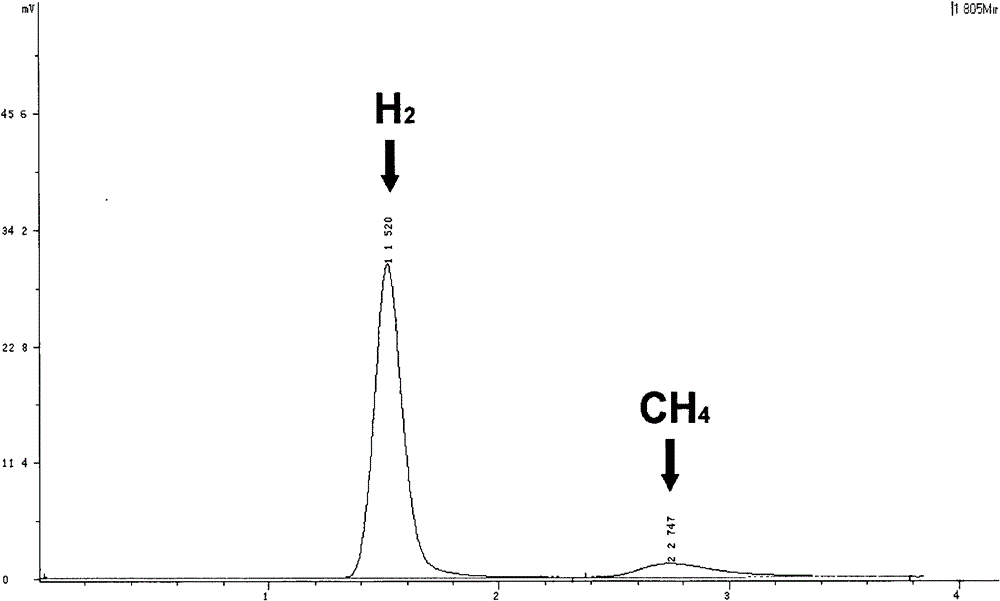

[0047] The method for preparing hydrogen by using the above-mentioned photocatalytic hydrogen production system is: use λ>400nm visible light to irradiate the sample, and monitor the sample once every 2 hours of illumination; after 10 hours of illumination, the calculated hydrogen production of the sample is about 17.6ml ( TON=505); the sample continued to produce hydrogen in the first ten hours, indicating that the system was...

Embodiment 2

[0051] A photocatalytic hydrogen production system containing polycarbonyl diiron disulfide cluster compounds: the concentration of water-soluble polycarbonyl diiron disulfide cluster compounds is 1.56×10 -4 M; concentration of MPA-CdTe QDs (as Cd 2+ Meter) is 5.00×10 -4 M; ascorbic acid (H 2 A) The concentration is 8.52×10 -3 M; the size of MPA-CdTeQDs is 3.4nm; the solvent is water; the total sample volume is 10ml; the pH of the sample before light is 2.0.

[0052] The method of preparing hydrogen by using the above photocatalytic hydrogen production system is: irradiate the sample with visible light of λ>400nm, and monitor the sample by gas spectrometer every 2 hours of light; after 8 hours of light, the calculated hydrogen production of the sample is about 0.12ml (TON=3); the sample continued to produce hydrogen in the first six hours, indicating that the system was basically stable during the first six hours of light.

[0053] The polycarbonyl diiron disulfide cluster...

Embodiment 3

[0055] A photocatalytic hydrogen production system containing polycarbonyl diiron disulfide cluster compounds: the concentration of water-soluble polycarbonyl diiron disulfide cluster compounds is 1.56×10 -4 M; concentration of MPA-CdTe QDs (as Cd 2+ Meter) is 5.00×10 -4 M; ascorbic acid (H 2 A) The concentration is 8.52×10 -3 M; the size of MPA-CdTeQDs is 3.4nm; the solvent is water; the total sample volume is 10ml; the pH of the sample before light is 3.0.

[0056] The method for preparing hydrogen by using the above-mentioned photocatalytic hydrogen production system is: irradiate the sample with visible light of λ>400nm, and monitor the sample by gas spectrometer every 2 hours of light; after 8 hours of light, the calculated hydrogen production of the sample is about 1.01ml (TON=29); the sample continued to produce hydrogen in the first six hours, indicating that the system was basically stable during the first six hours of light.

[0057] The polycarbonyl diiron disul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com