Resin composition, and prepreg and printed circuit board made from same

A resin composition and technology of the composition, applied in the directions of printed circuit parts, circuit substrate materials, layered products, etc., can solve the problems of different product properties, difficult to control quality, and difficult to master the degree of polymerization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

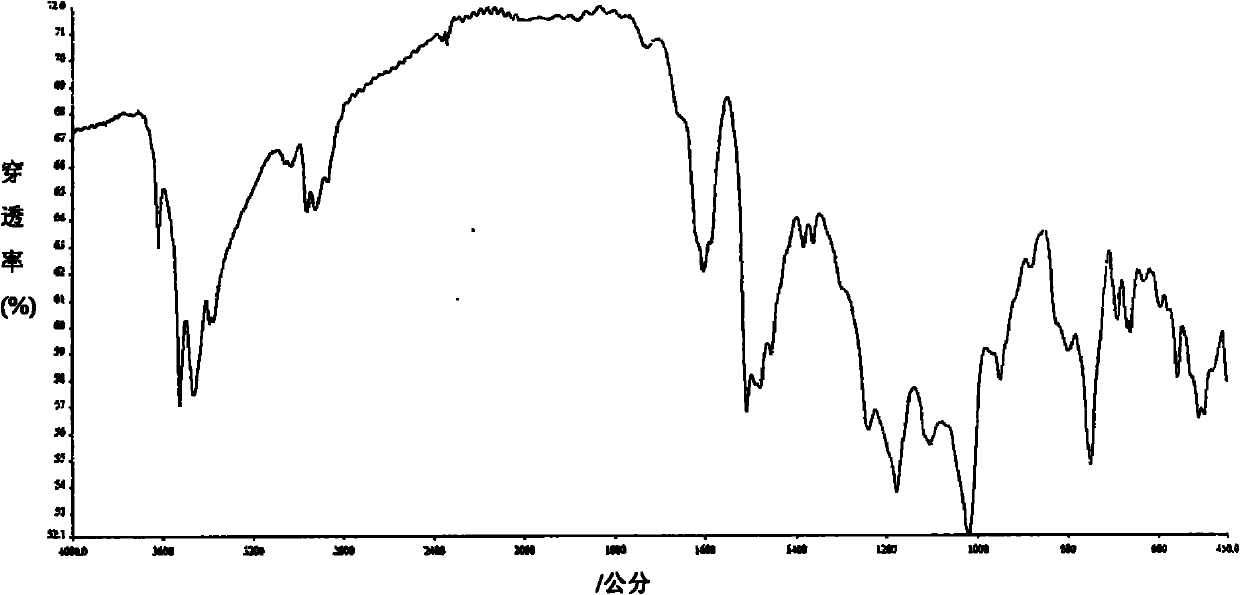

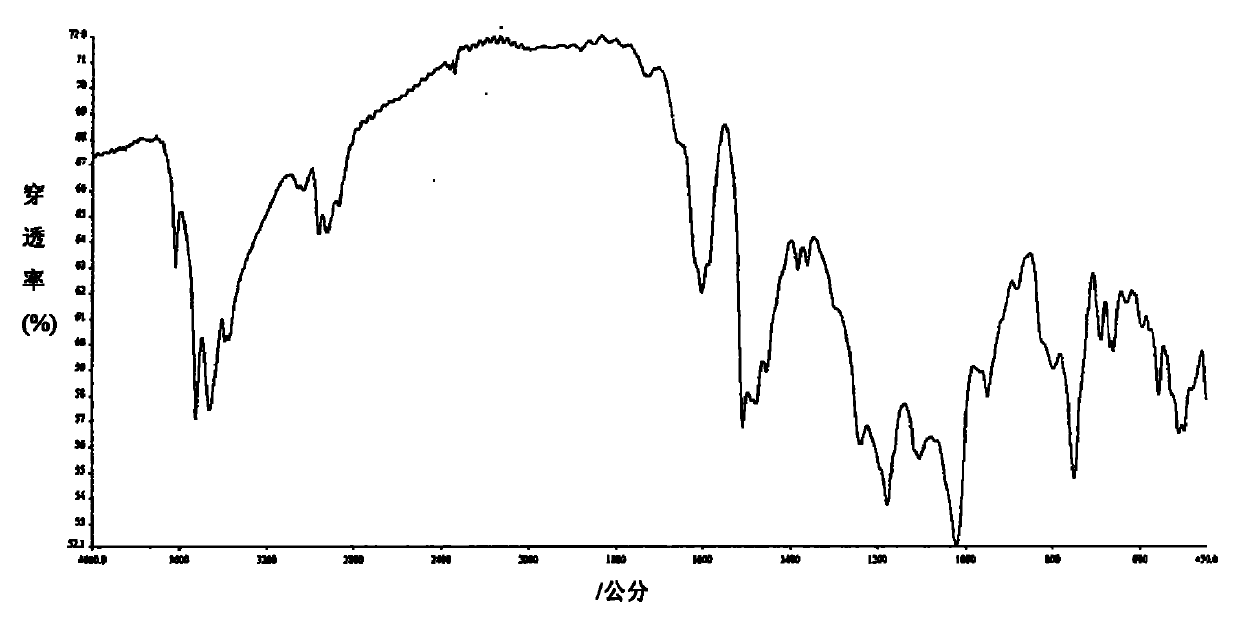

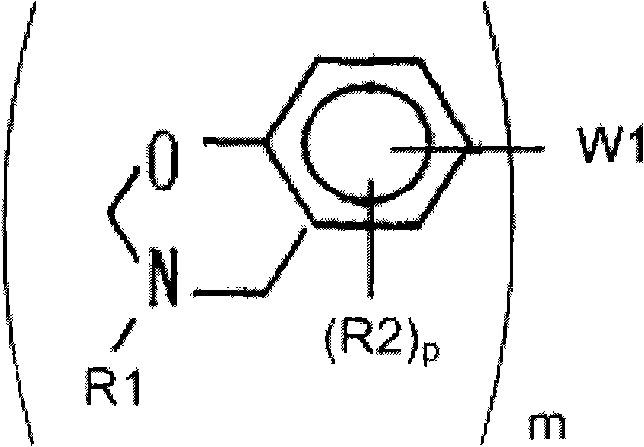

Image

Examples

Embodiment 1

[0103] As shown in the ratio of Table 1, 100 parts by weight of DOPO epoxy resin (Kolon5138), 0.5 parts by weight of 2-methylimidazole, 0.5 parts by weight of epoxy silane coupling agent (Shin-Etsu Chemical, KBM-403), 20 parts by weight of phosphazene flame retardant (Otsuka Chemical, SBP-100), 50 parts by weight of talc and 80 parts by weight of polymer solution 1-1 (in terms of solids), use a stirrer to mix at room temperature for 60 Minutes, then add the butanone of 80 weight parts again. After the above mixture was stirred at room temperature for 120 minutes, resin composition 1 was obtained.

Embodiment 2

[0105] Resin composition 2 was prepared in the same manner as in Example 1, except that 80 parts by weight of polymer solution 1-2 (calculated as solids) was used instead of polymer solution 1-1 as the hardener, as shown in Table 1.

Embodiment 3

[0107] Resin composition 3 was prepared in the same manner as in Example 1, except that 80 parts by weight of polymer solution 1-3 (calculated as solids) was used instead of polymer solution 1-1 as the hardener, as shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com