Closed-type electro-winning cell

An electrowinning cell and closed technology, which is applied in electrolytic components, electrolytic processes, cells, etc., can solve the problems of increased metal impurities, electrical efficiency, slowing down of metal electrowinning, etc., to reduce gas-liquid interface corrosion and eliminate concentration polarization , the effect of reducing the content of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below with reference to the accompanying drawings.

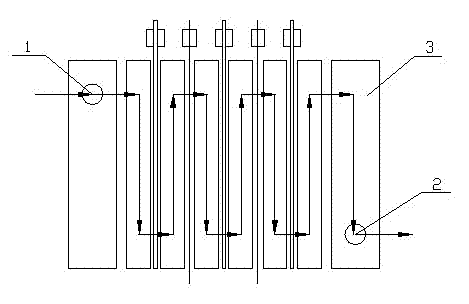

[0019] see figure 1 , the electrolyte of the existing closed electrowinning cell enters from the liquid inlet 1 of the end plate 3 on one side of the electrowinning cell, passes through the liquid through holes on the cathode and anode plates, and then sequentially passes through a group of cathodes and anodes connected in series. Electrolyte positive chamber, and then flow out from the liquid outlet of the other side end plate 3, and the electrolyte flow process is serial flow.

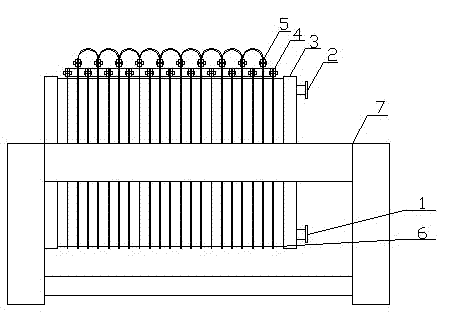

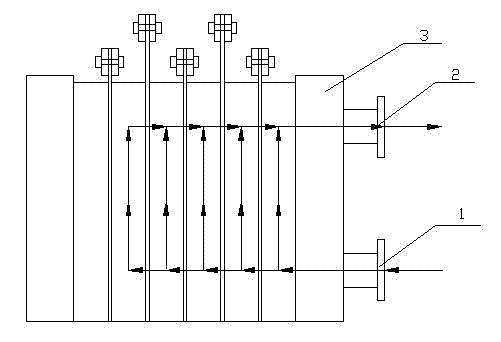

[0020] see figure 2 and image 3 , The present invention provides a closed electrowinning cell with parallel flow of electrolyte, including end plate 3 , cathode plate 4 , anode plate 5 , seals, pressing device 7 and insulating plate frame 6 . The end plate 3 is made of organic material or steel-lined organic material, which has the properties of corrosion resistance, insulation, high str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com