Anticorrosion method of chimney used for discharging wet-method desulfurized fume

A technology of wet desulfurization and chimney, which is applied in the direction of combustion method, exhaust gas device, combustion product treatment, etc. It can solve the problems such as difficulty in guaranteeing the quality of lining block gaps, endless corrosion cases, and difficulty in achieving anti-corrosion effects, etc., to ensure quality , Can be designed with strong performance and avoid the effect of on-site manufacturing work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

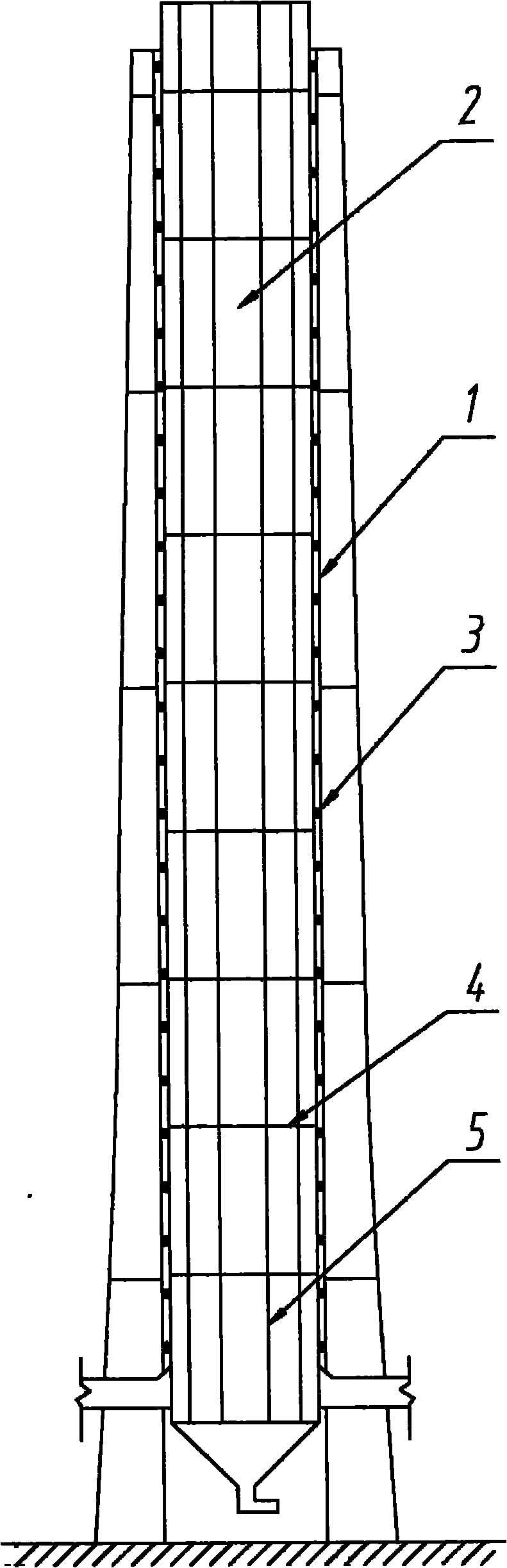

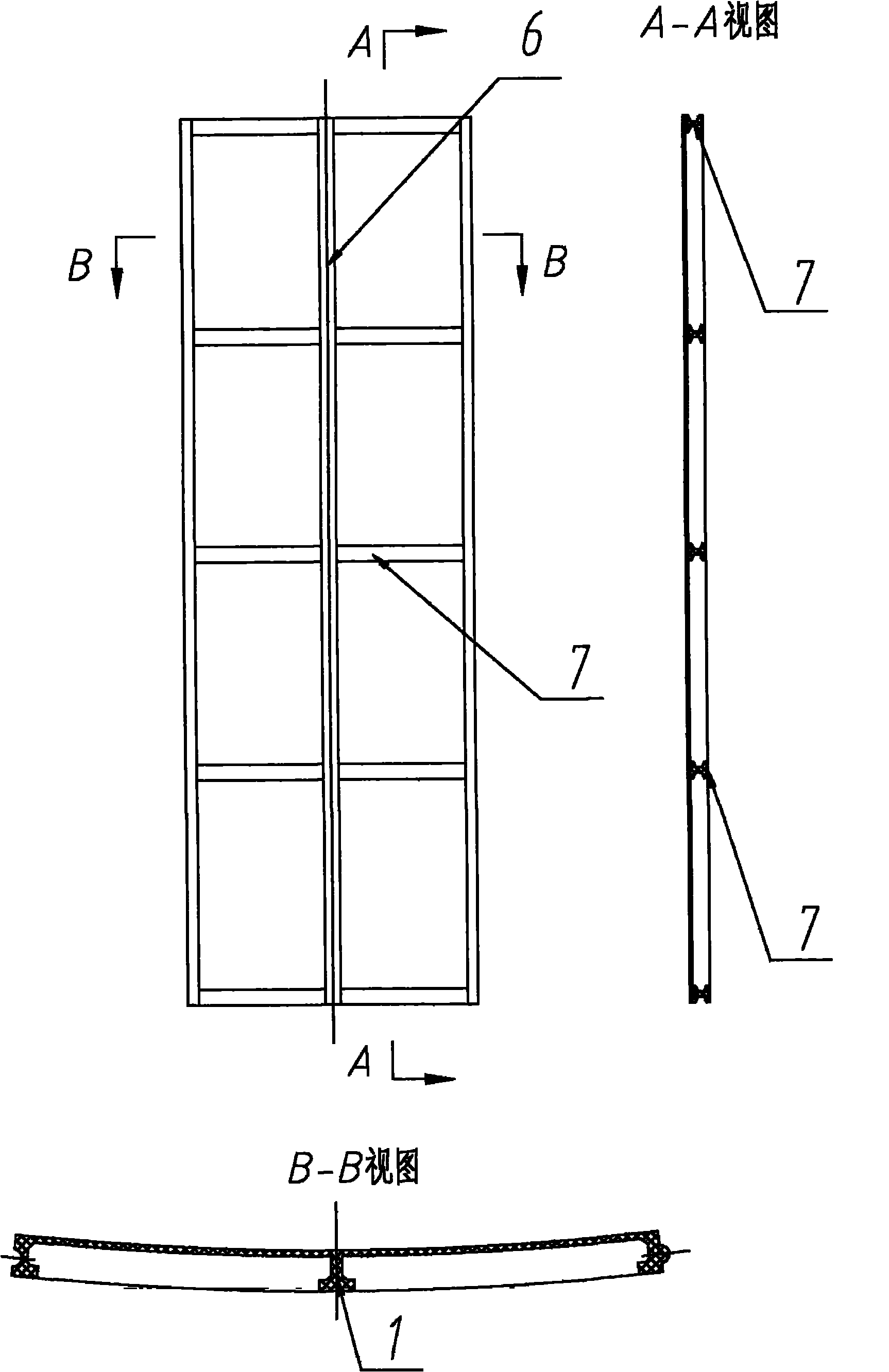

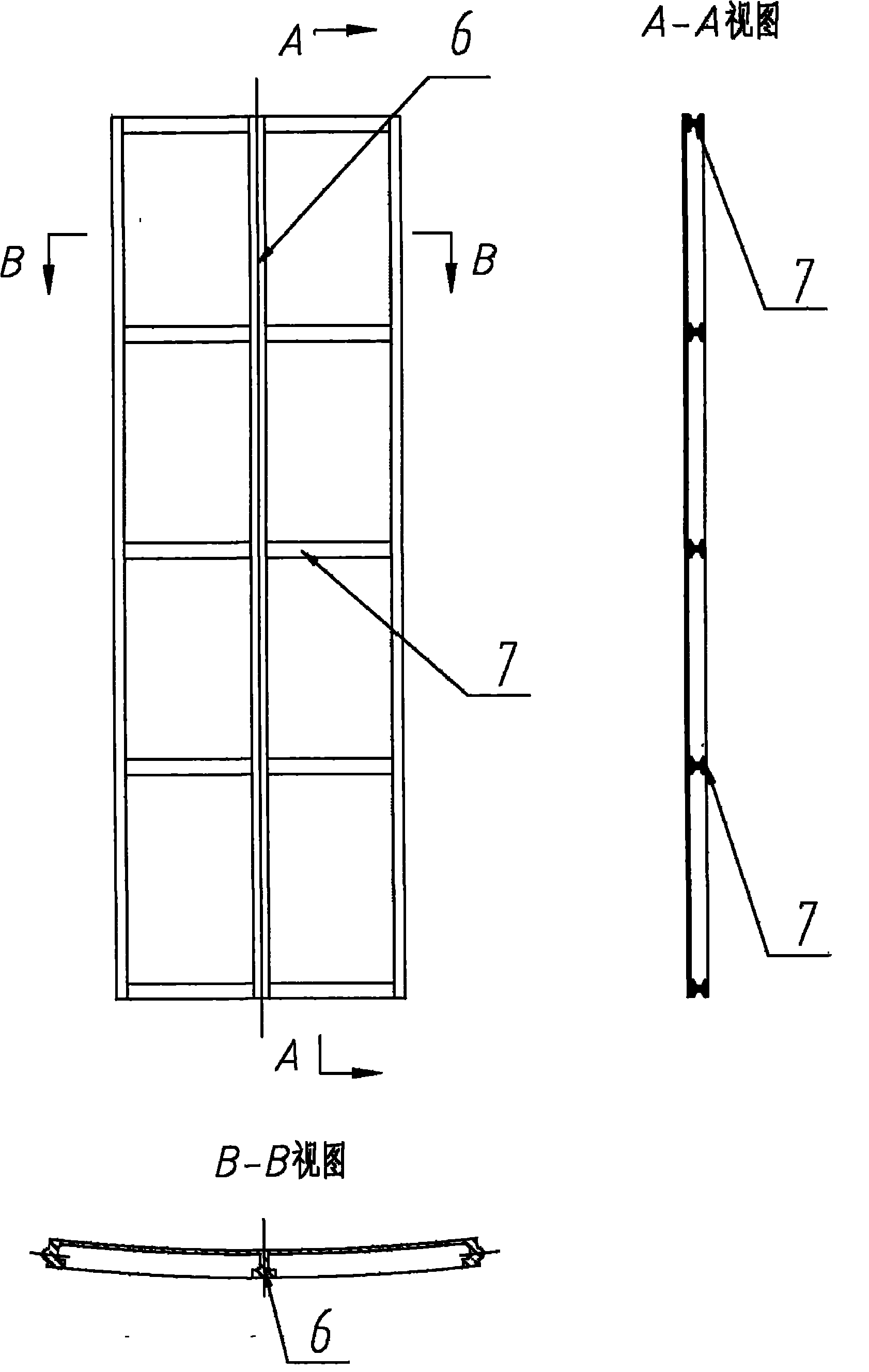

[0043] The present invention proposes a method for anticorrosion of flue gas chimneys after wet desulfurization. The method is as follows: according to the specific structural shape of the inner surface of the chimney exhaust pipe 1, a glass fiber reinforced plastic protective plate 2 with a reasonable size is designed; the glass reinforced plastic protective plate 2 By hanging ( Figure 4a ), bolted ( Figure 4b ), bonded or welded fixing point 3 is fixed on the inner surface of the chimney exhaust pipe 1; the glass fiber reinforced plastic protective plate 2 is connected 4 and circumferentially connected 5 along the longitudinal direction of the chimney, thereby forming an integral glass fiber reinforced plastic protection suitable for the inner surface of the chimney The structure of the glass fiber reinforced plastic protective tube is airtight, which can effectively prevent the leakage of flue gas and avoid the corrosion of the chimney by the flue gas after wet desulfuriz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com