Method of forming isolation structure and semiconductor device with the isolation structure

An isolation structure and semiconductor technology, which is applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of inability to provide electrical isolation characteristics, restrict the flow of dielectric materials, etc., and achieve the effect of good electrical isolation characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

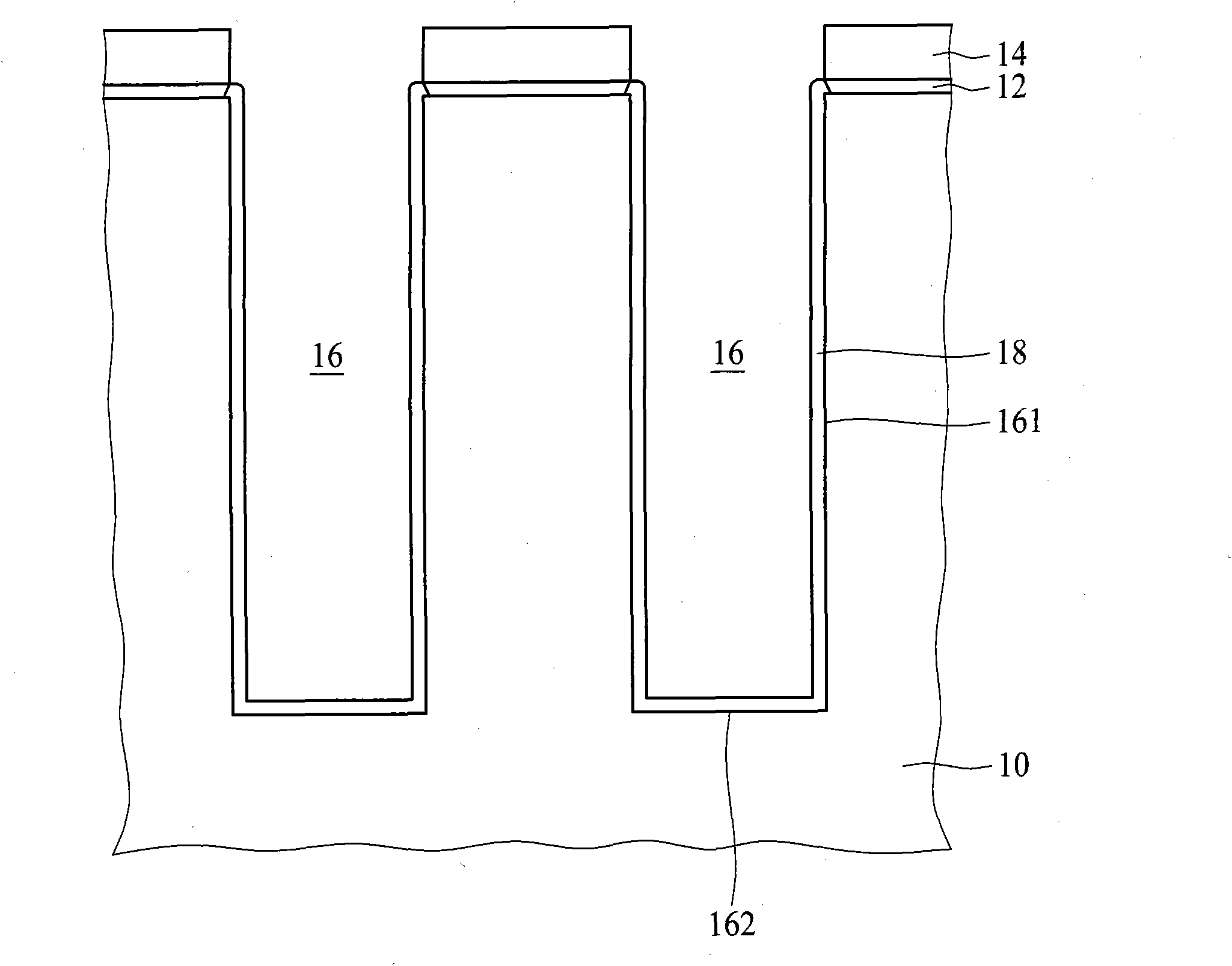

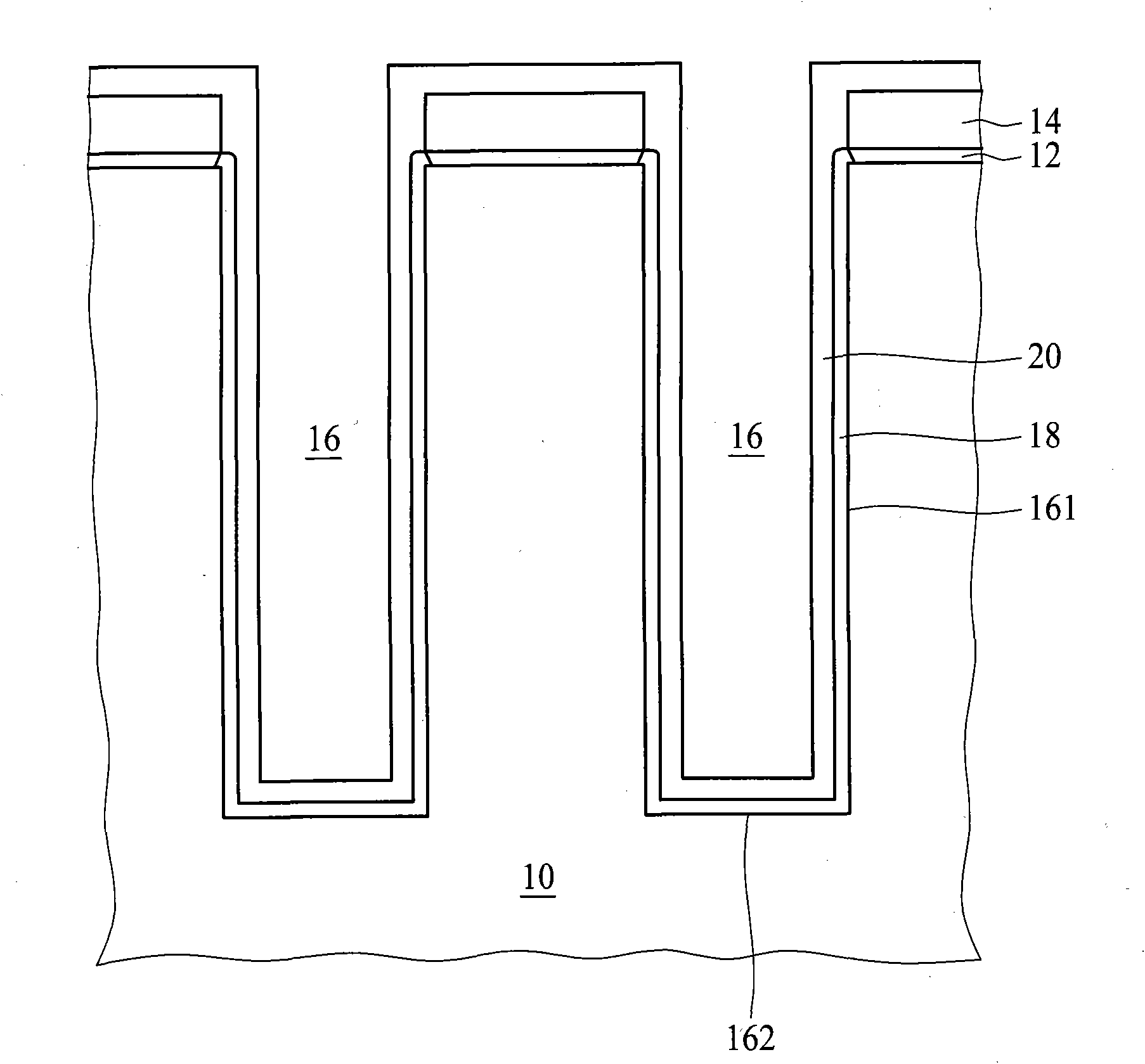

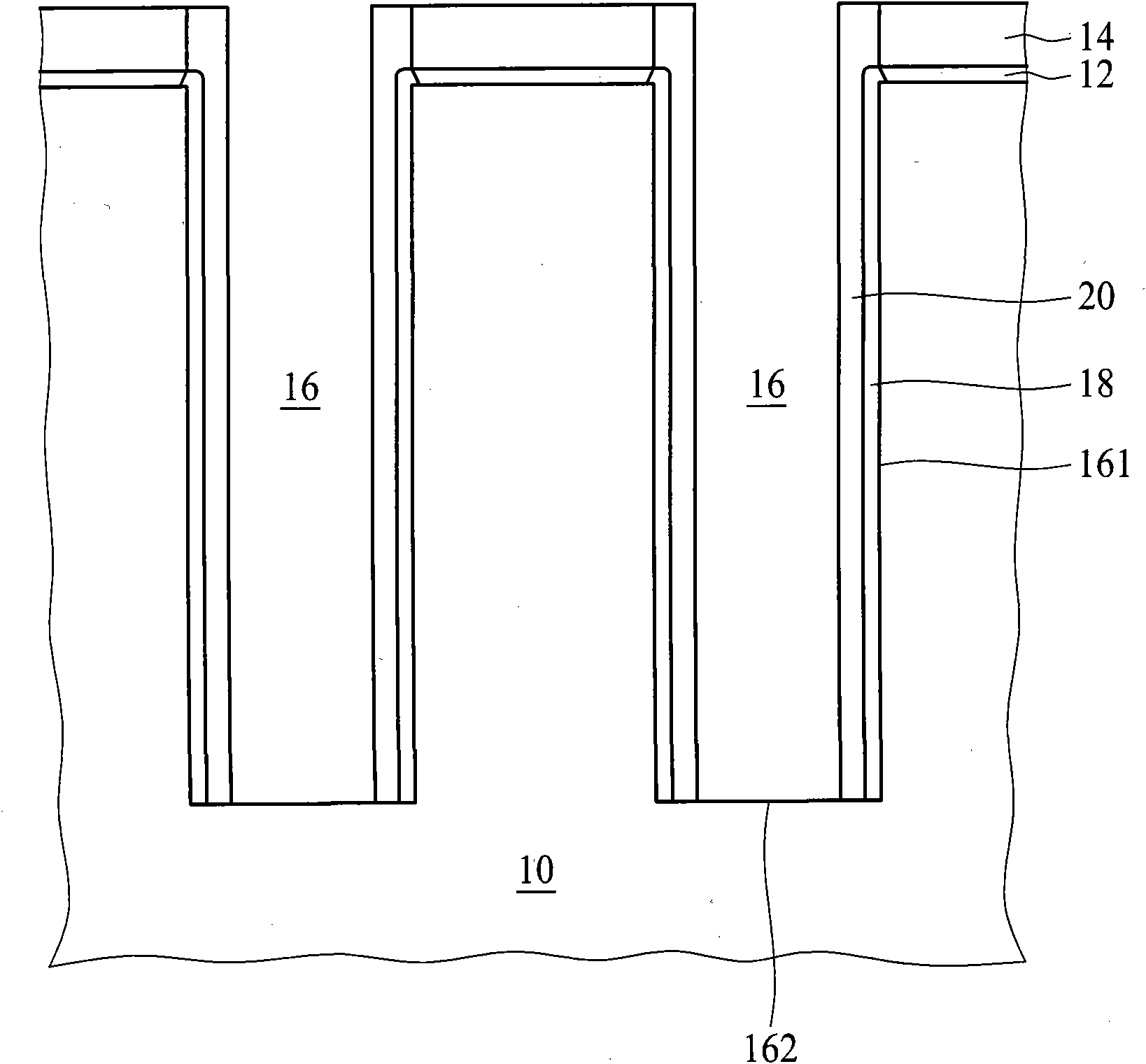

[0030] In one embodiment of the present invention, the dielectric material is first formed on the lower portion of the trench to reduce the filling depth of the trench, so that conventional deposition techniques can be applied to fill the trench. In an embodiment of the present invention, the lower portion of the trench can be filled with a dielectric material or a substance that can be oxidized into a dielectric material. Afterwards, the upper portion of the trench (that is, above the filled dielectric material) can be filled with a spin-on dielectric material or a chemical vapor deposition dielectric material.

[0031] In one embodiment of the present invention, the lower portion of the trench can be filled with epitaxial silicon, which can be converted to silicon oxide in a subsequent thermal oxidation process. In this embodiment, the nitride liner can be formed on the sides of the trench, and the epitaxial silicon can be selectively grown on the bottom of the trench and no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com