Methods for preparing silver nano-particles and conductive nano-film of silver nano-particles

A technology of silver nanoparticles and silver salts, applied in metal material coating process, coating and other directions, can solve problems such as being unfavorable to environmental protection and increasing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

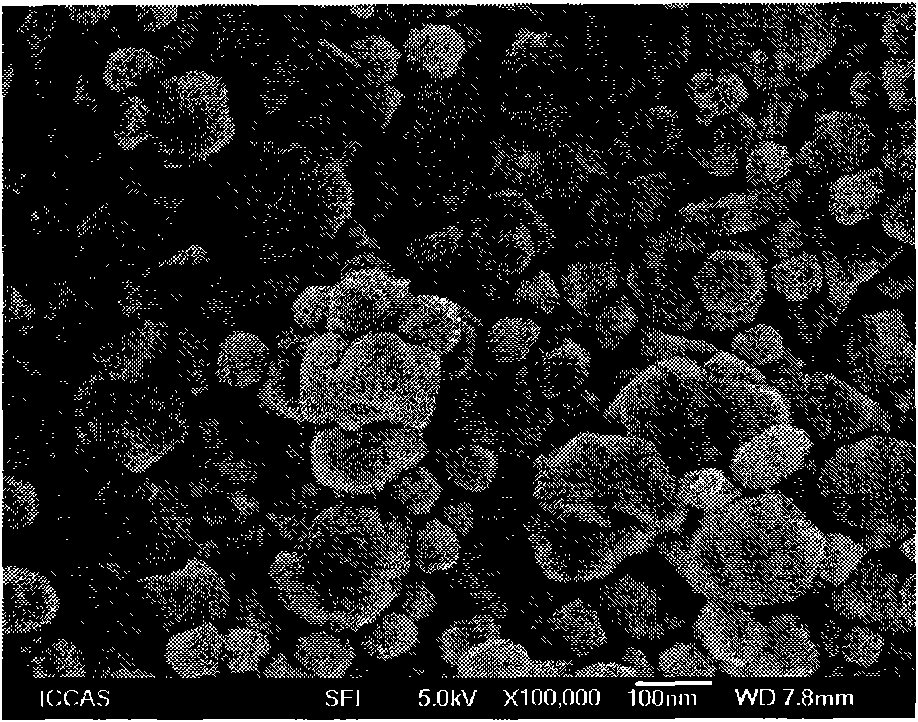

[0027] Embodiment 1, prepare silver nanoparticle and silver nanofilm

[0028] Add 1M ethylenediaminetetraacetic acid salt solution (pH=7.0, EDTA dissolved in 10M NaOH solution, add water to 1M) dropwise to 70g 0.1wt% (0.0004mol) AgNO 3 In the aqueous solution, until the solution turns from cloudy to clear, a total of 0.61 mL of ethylenediaminetetraacetic acid salt solution is consumed. 0.0454g (0.0004mol) of catechol was dissolved in 20g of water to obtain a catechol solution. Add the catechol solution dropwise to the prepared AgNO chelated with EDTA 3 In the solution, stirring is applied at the same time, the speed is 600 rpm, and the reaction temperature is 25°C. The dropwise addition was completed in 1 hour, and the reaction was continued for 1 hour to stop the reaction, and the solution turned gray-black. The resulting product was precipitated by centrifugation, washed with water, and repeated three times. The obtained silver nanoparticles were redispersed in 30mL of w...

Embodiment 2

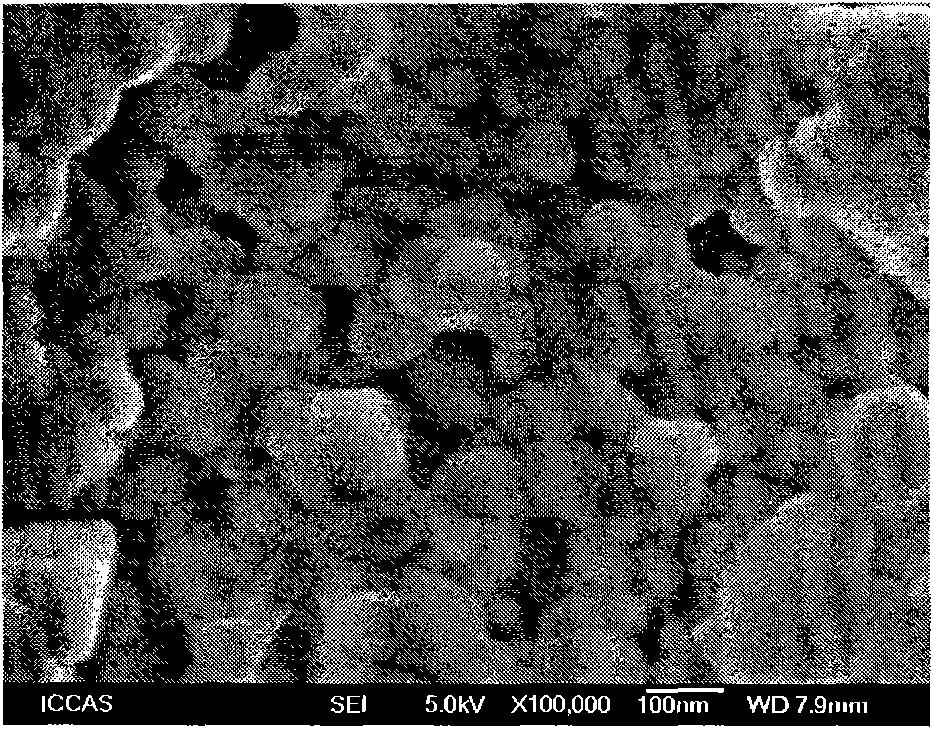

[0029] Embodiment 2, preparation silver nanoparticle and silver nanofilm

[0030] Add 1M ethylenediaminetetraacetic acid salt solution (pH=7.0, EDTA dissolved in 10M NaOH solution, add water to 1M) dropwise to 70g 0.2wt% (0.0008mol) AgNO 3 In the aqueous solution, until the solution turns from cloudy to clear, a total of 1.34 mL of ethylenediaminetetraacetic acid salt solution was consumed. 0.0908g (0.0008mol) of catechol was dissolved in 20g of water to obtain a catechol solution. Slowly drop the catechol solution into the prepared EDTA chelated AgNO 3 In the solution, stirring is applied at the same time, the speed is 800 rpm, and the reaction temperature is 40°C. The dropwise addition was completed in 1 hour, and the reaction was continued for 1 hour to stop the reaction, and the solution turned gray-black. The resulting product was precipitated by centrifugation, washed with water, and repeated three times. The obtained silver nanoparticles were redispersed in 30 mL of...

Embodiment 3

[0031] Embodiment 3, preparation silver nanoparticle and silver nanofilm

[0032] A 1.5 M EDTA salt solution (tetrasodium EDTA was dissolved in water, and then adjusted to pH 7.0) was added dropwise to 70 g of 0.4 wt% (0.0016 mol) AgNO 3 In the aqueous solution, until the solution turns from cloudy to clear, a total of 1.83 mL of ethylenediaminetetraacetic acid salt solution was consumed. 0.1816g (0.0016mol) of catechol was dissolved in 40g of water to obtain a catechol solution. Add the catechol solution dropwise to the prepared AgNO chelated with EDTA 3 In the solution, stirring is applied at the same time, the speed is 900 rpm, and the reaction temperature is 80°C. The dropwise addition was completed in 1.5 hours, and the reaction was continued for one hour to stop the reaction, and the solution turned gray-black. The resulting product was precipitated by centrifugation, washed with water, and repeated three times. Gained silver nanoparticles were redispersed in 30mL of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com