Production process and production line of automatically-installed decorating strip

A technology of automatic installation and production process, which is applied in lamination devices, layered products, manufacturing tools, etc. It can solve the problems of uneven manual glue application, damage to the outer surface of wooden door frames, and low work efficiency, so as to achieve mass production , Increase per capita production capacity and reduce work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

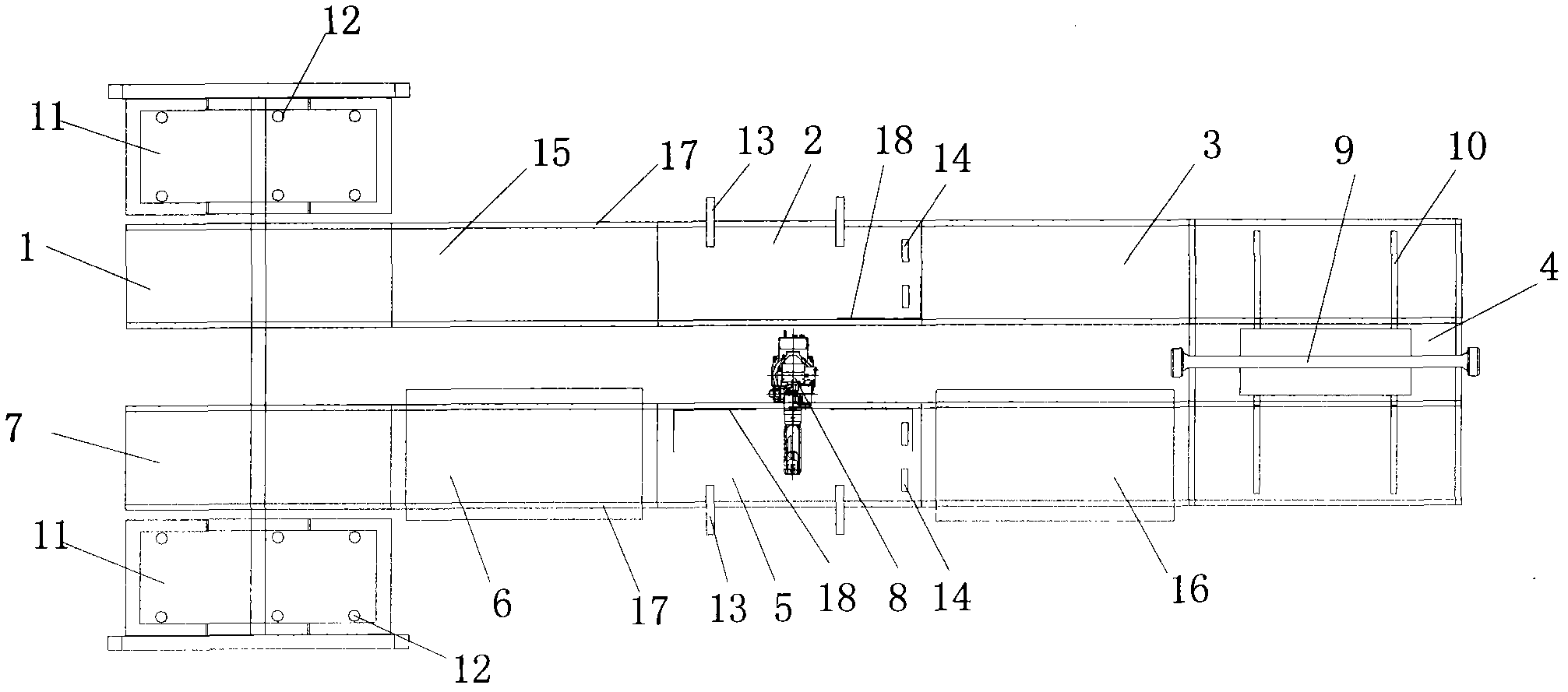

[0038] The present invention will now be described in further detail in conjunction with the accompanying drawings and preferred embodiments. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0039] Such as figure 1 As shown, a production process for automatically installing decorative strips includes the following process steps: feeding, the workpiece is placed on the conveyor belt 14 through the feeding device 1, and transported to a predetermined position; positioning, the workpiece is transferred to the first positioning device Accurate positioning at 2 places; gluing, after positioning the workpiece, apply glue to the position where the decorative strip needs to be installed on the workpiece through the gluing device 8; pressing, after the gluing workpiece is placed with the decorative strip, it is sent to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com