Forming method for molecular sieve

A molding method and technology of molecular sieves, which are applied in the direction of molecular sieve catalysts, chemical instruments and methods, and other chemical processes, can solve the problems of molecular sieve structure damage safety, environmental protection, etc., and achieve small structural damage, good technical effects, and small environmental impacts Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The alumina and molecular sieves for molding are purchased commercial alumina and commercial 13X molecular sieve raw powder respectively.

[0017] Add nitric acid molding

[0018] Mix 0.4kg of 13X molecular sieve raw powder, 1.5kg of alumina and 50g of turnip powder in a kneader, stir evenly, add 1.1kg of dilute nitric acid solution with a weight concentration of 3%, knead, extrude into strips, dry and place in a horse In a Furnace, it was fired at 520°C for 4h, and the diameter of the molded sample was 2.5mm, named as sample A.

[0019] Add aluminum nitrate solution molding

[0020] Mix 0.4kg of 13X molecular sieve raw powder, 1.5kg of alumina and 50g of turnip powder in a kneader, stir evenly, add 1.0kg of aluminum nitrate solution with a weight concentration of 7%, knead, extrude into strips, dry and place in a horse In the Furnace, it was fired at 520°C for 4h, and the diameter of the molded sample was 2.5mm, named as sample B.

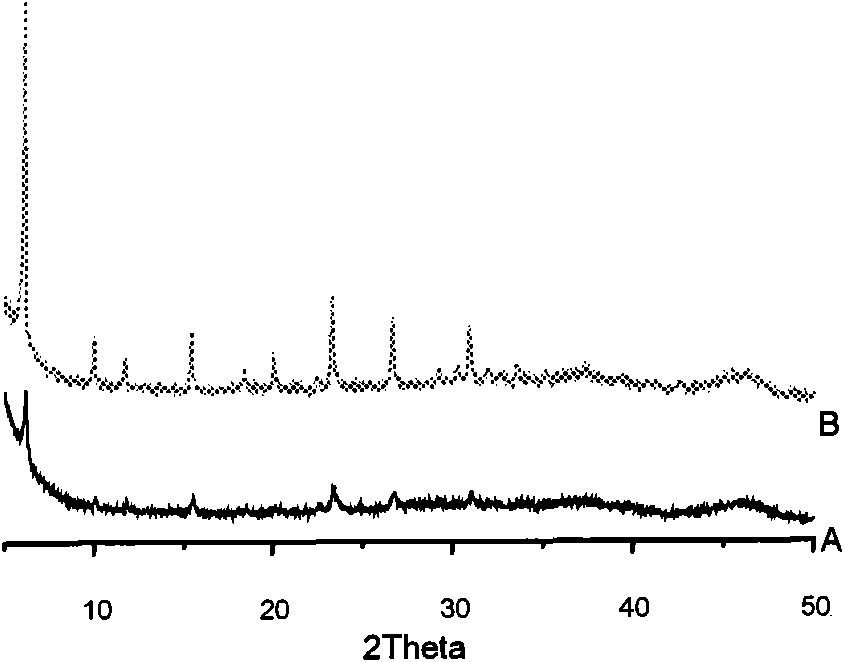

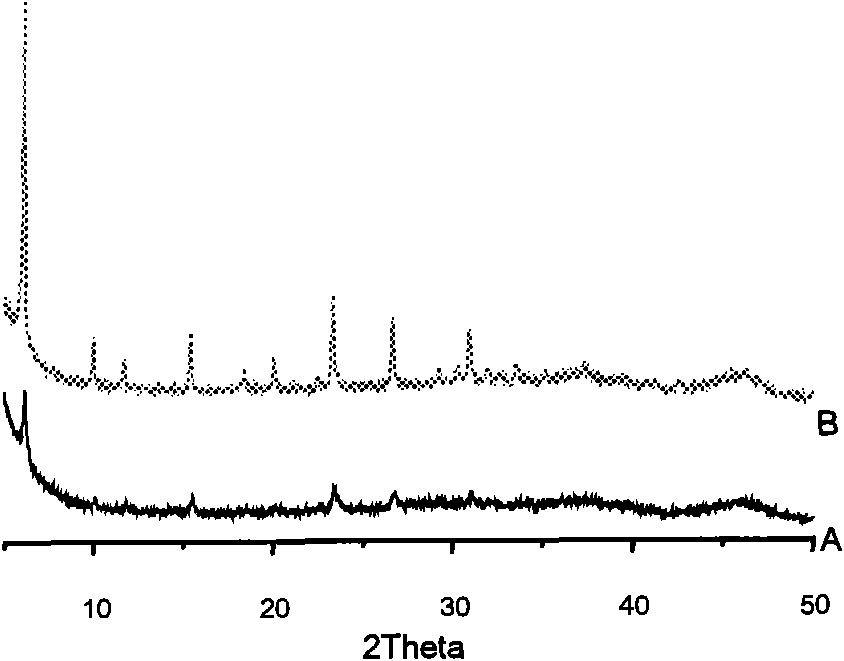

[0021] The properties of sample A...

Embodiment 2

[0032] The alumina and molecular sieves used for molding are purchased commercial alumina and commercial NaY molecular sieve raw powder respectively.

[0033] Add nitric acid molding

[0034] Mix 1.2kg of NaY molecular sieve raw powder, 0.8kg of alumina and 50g of turnip powder in a kneader, stir evenly, add 1.1kg of dilute nitric acid solution with a weight concentration of 5%, knead, extrude into strips, dry and place in a horse In the Furnace, it was fired at 520°C for 4h, and the diameter of the molded sample was 2.5mm, named as sample C.

[0035] Add aluminum nitrate solution molding

[0036] Mix 1.2kg of NaY molecular sieve raw powder, 0.8kg of alumina and 50g of turnip powder in a kneader, and after stirring evenly, add 1.1kg of aluminum nitrate solution with a weight concentration of 10.4%, knead and extrude into strips, dry and place in a horse In the Furnace, it was fired at 520°C for 4h, and the diameter of the molded sample was 2.5mm, named as sample D.

[0037]...

Embodiment 3

[0045] The alumina and molecular sieves for molding are purchased commercial alumina and commercial 5A molecular sieve raw powder respectively.

[0046] Add nitric acid molding

[0047] Mix 0.2kg of 5A molecular sieve raw powder, 1.8kg of alumina and 50g of turnip powder in a kneader, stir evenly, add 1.0kg of dilute nitric acid solution with a weight concentration of 5%, knead, extrude into strips, dry and place in a horse In the Furnace, it was fired at 520°C for 4h, and the diameter of the molded sample was 2.5mm, named as sample E.

[0048] Add aluminum sulfate solution molding

[0049] Mix 0.2kg of 5A molecular sieve raw powder, 1.8kg of alumina and 50g of turnip powder in a kneader, and after stirring evenly, add 1.1kg of aluminum sulfate solution with a weight concentration of 2%, knead, extrude and form, dry and place in a horse In the Furnace, it was fired at 520°C for 4h, and the diameter of the molded sample was 2.5mm, named as sample F.

[0050] The various perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com