Novel material for needled carpet of car

A car and needle punching technology, applied to carpets, etc., to achieve good low temperature resistance, easy processing and molding, and a wide range of hardness effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0031] raw material

Embodiment 3

[0034] The new materials for automotive needle-punched carpets produced in the above three embodiments were sampled and tested respectively, and the test results showed that their physical properties were better than existing products. Wherein the test result of embodiment 3 is optimal.

[0035] Now select two of the products in Example 3, numbered 7821B-NB-7 and 8522B-NB, and disclose their test results. The test result data are as follows:

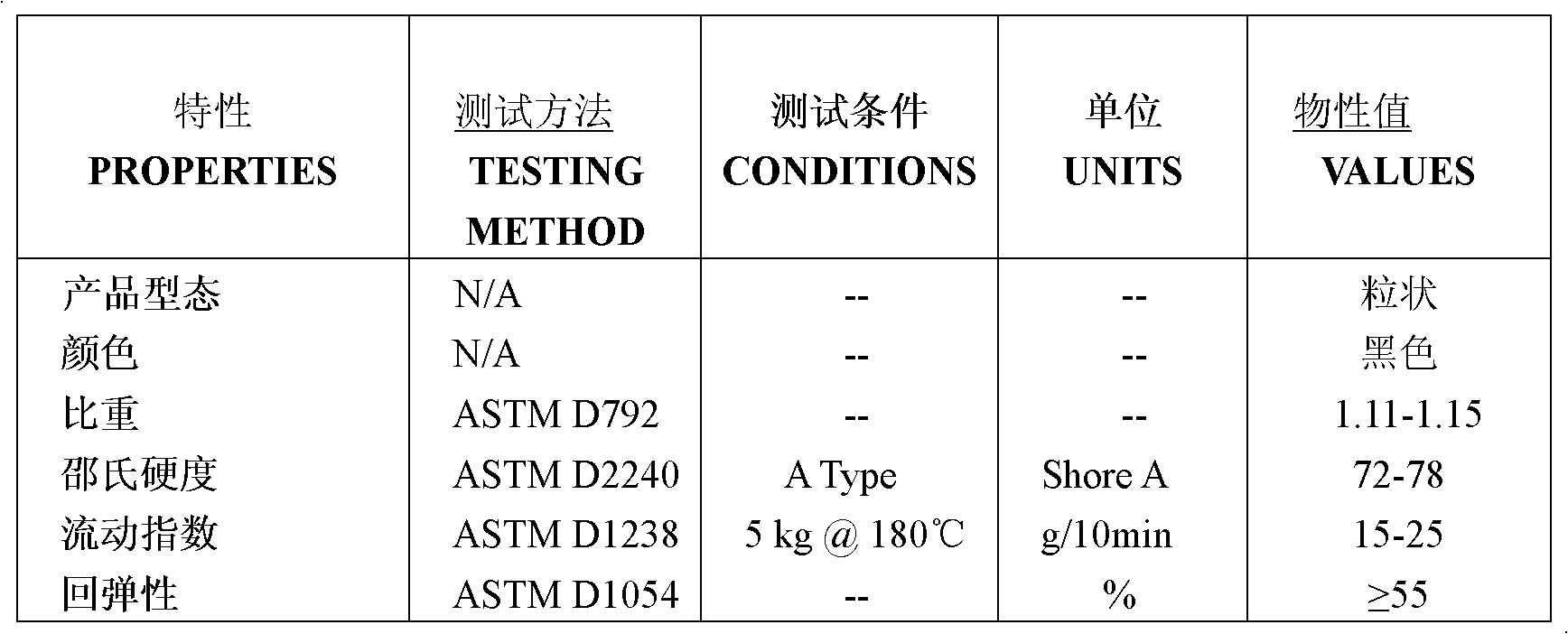

[0036] a. 7821B-NB-7 physical properties:

[0037]

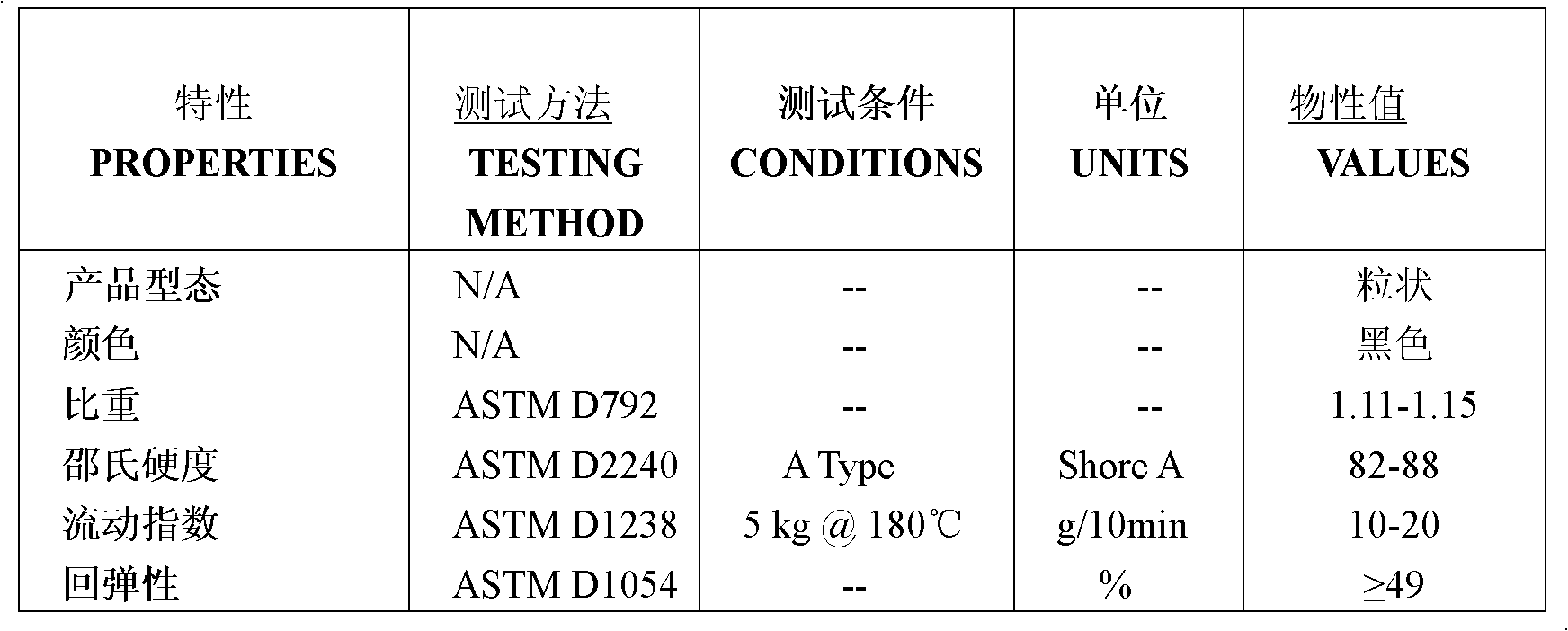

[0038] b. 8522B-NB physical properties:

[0039]

[0040] The performance of the above-mentioned products is excellent, that is to say, the new-type automotive needle-punched carpet materials produced are suitable for market promotion.

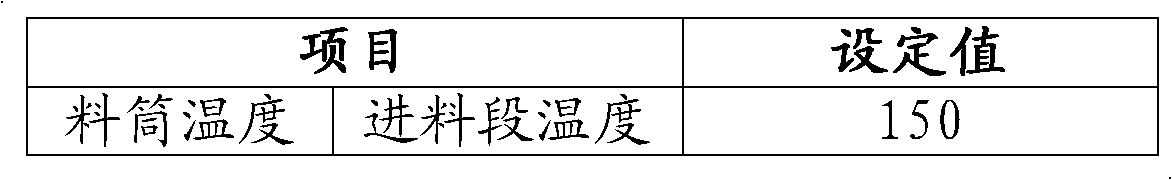

[0041] Using the above 7821B-NB-7 and 8522B-NB to process injection molded automotive needle-punched carpets requires:

[0042]

[0043]

[0044] The injection molded T-7821B-NB-7 and T-8522B-NB all meet the physical properties of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com