Electrostatic coalescer for separating oil from water

A technology of electrostatic coalescence and oil-water separation, which is applied in the direction of electrical separation of liquids, electrical/magnetic dehydration/demulsification, etc. It can solve the problems of pollution, oil-water separation, and high water content of produced crude oil, and achieve good results and rapid separation. , Improve the effect of water-oil separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

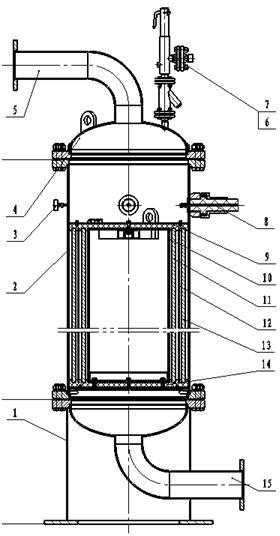

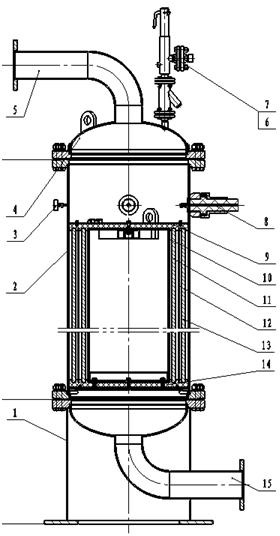

[0011] exist figure 1 Among them, the present invention is provided with cylinder body 2, and cylinder body 2 is installed on base 1, and instrument 3 is installed on cylinder body 2, and the bottom of cylinder body 2 is processed with oil outlet 15, and the top of cylinder body 2 is processed with oil inlet 5. A filter 6 and a safety valve 7 are installed on the top cover 4 of the cylinder 2, a high-voltage wiring joint 8 is fixed on the side wall above the cylinder 2, and the inner cavity of the cylinder 2 is sequentially fitted with cylindrical insulation Electrode B13, grounding electrode B12, insulating electrode A11 and grounding electrode A10, the upper and lower ends of insulating electrode B13, grounding electrode B12, insulating electrode A11, and grounding electrode A10 are respectively equipped with insulating top plate 9 and insulating bottom plate 14, insulating electrode B13, insulating electrode A11 is electrically connected to the high-voltage connection joint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com