Heat-conducting double-faced soft and hard combined base plate and manufacturing method thereof

A combination of soft and hard, substrate technology, applied in the direction of circuit substrate materials, printed circuit manufacturing, printed circuit components, etc., can solve the problems of high junction temperature, no deflection, hard material, etc., to achieve high heat conduction efficiency, durability Breakdown voltage, effect of high breakdown voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

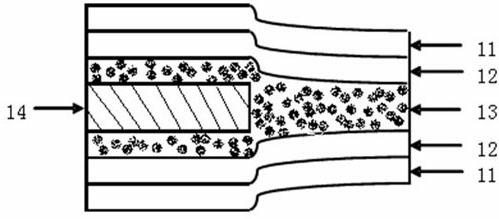

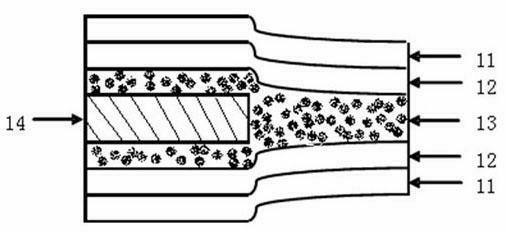

[0024] Example: a thermally conductive double-sided rigid-flex substrate, comprising a copper foil layer 11, an aluminum plate 14, an insulating thermally conductive polymer layer 12 and an adhesive layer 13, the insulating thermally conductive polymer layer 12 is fixedly attached to both sides of the adhesive layer 13 , the copper foil layer 11 is fixedly attached to the two outer sides of the insulating and thermally conductive polymer layer 12, the aluminum plate 14 is fixedly arranged inside the adhesive layer 13, the surface area of the aluminum plate 14 is smaller than the surface area of the adhesive layer 13, and the insulating and thermally conductive polymer layer is 12 includes solid material and heat-dissipating powder, and adhesive layer 13 includes resin layer and heat-dissipating powder. Of course, the insulating and thermally conductive polymer layer may include accelerators, catalysts, etc. in addition to solid materials and heat-dissipating powder. The hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com