Method of making cefquinome particles

A technology of cefquinome and splequinme, which is applied in the field of production of cefquinome acid addition salt granules, and can solve the problems of reducing particle size and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

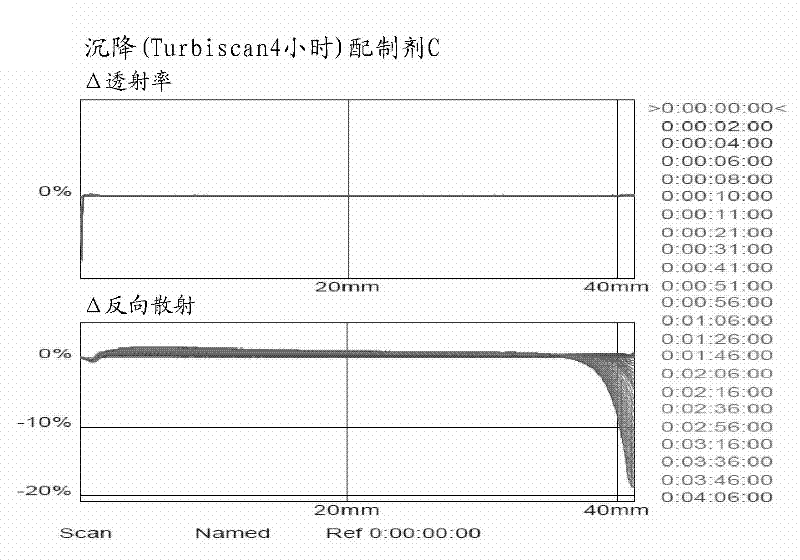

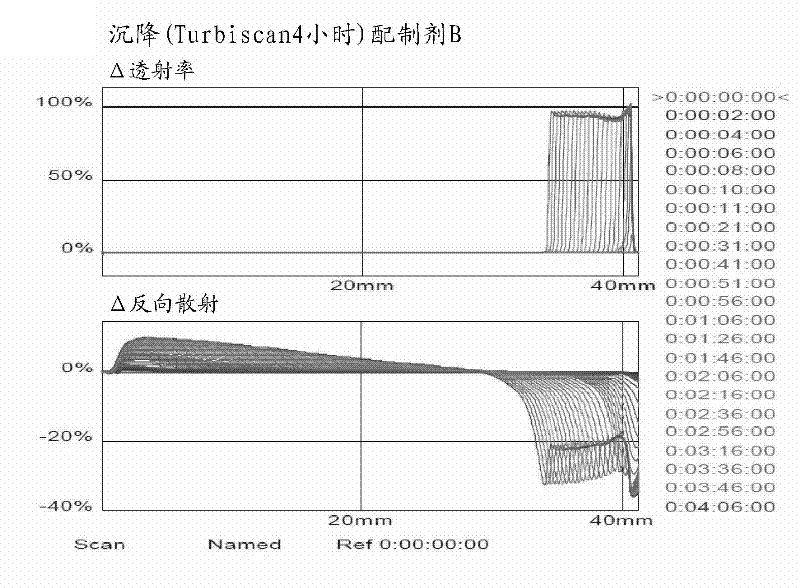

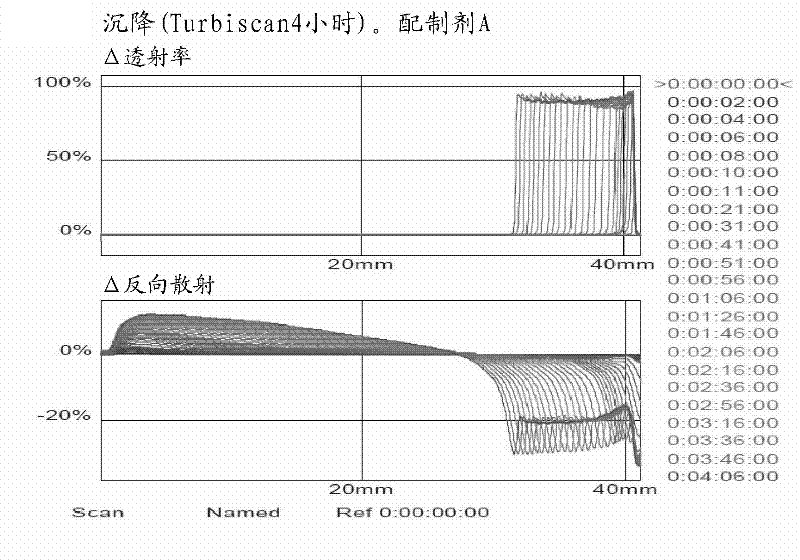

Embodiment 1

[0059] Suspend 250.3 g of cefquinome sulfate in 740 ml of water at a temperature below 10 °C, then add 150 ml of 16.3% NaOH, followed by 1020 ml of acetone to precipitate sodium sulfate (Na 2 SO 4 ). After filtering and washing the salt with 375 ml of a mixture of acetone / water=1.27 / 1, the combined liquid was decolorized by treatment with 21 g of charcoal. After washing the charcoal with 150 ml of acetone / water=2 / 1, the combined liquid mixture was heated to 19° C., and then 388 ml of 15.1% sulfuric acid were added within 5 minutes. Stirring of the reaction mixture was continued at 19-21 °C for 35 min, then 1200 ml of acetone were added. With stirring, the suspension was poured into 12400 ml of acetone. After filtration and washing twice with 2500 ml of acetone, the precipitate was dried overnight at 32°C to yield 225 g of material for the preparation of ethyl oleate formulations A, B or C. The material was sampled for particle size distribution (PSD) measurements after add...

Embodiment 2

[0062] Corresponding to the method described in Example 1, 1200ml of water and 500g of cefquinome sulfate were reacted with 350g of 16.3% NaOH and 1325ml of acetone at 5°C. Both the salt and 15 g of charcoal were washed with 300 ml of acetone / water=3 / 1 each, followed by an additional charcoal wash with 215 ml of acetone / water=3.3 / 1, resulting in 3472 g of combined liquid, which was Used as stock solution. This stock solution was divided into three equal portions and used in Examples 2-1, 2-2 and 2-3.

Embodiment 2-1

[0064] A portion of 1158 g of the stock solution was heated to 18°C. 334 ml of acetone were added, followed by 286 g of a 15.1% dose of sulfuric acid within 5 minutes. The reaction mixture was stirred and then diluted with 800 ml of acetone with continuous stirring. The material was sampled for particle size distribution (PSD) measurements after addition of sulfuric acid and immediately before addition of acetone. Ultrasound is applied for 60 seconds.

[0065] PSD: D(100)=104.71 μm; D(90)=36.24 μm; D(50)=9.67 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com