Sensing device

A technology of detection equipment and detectors, which is applied in the direction of testing/calibration of speed/acceleration/shock measurement equipment, measuring devices, measuring devices, etc., and can solve problems such as increasing system costs and error detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

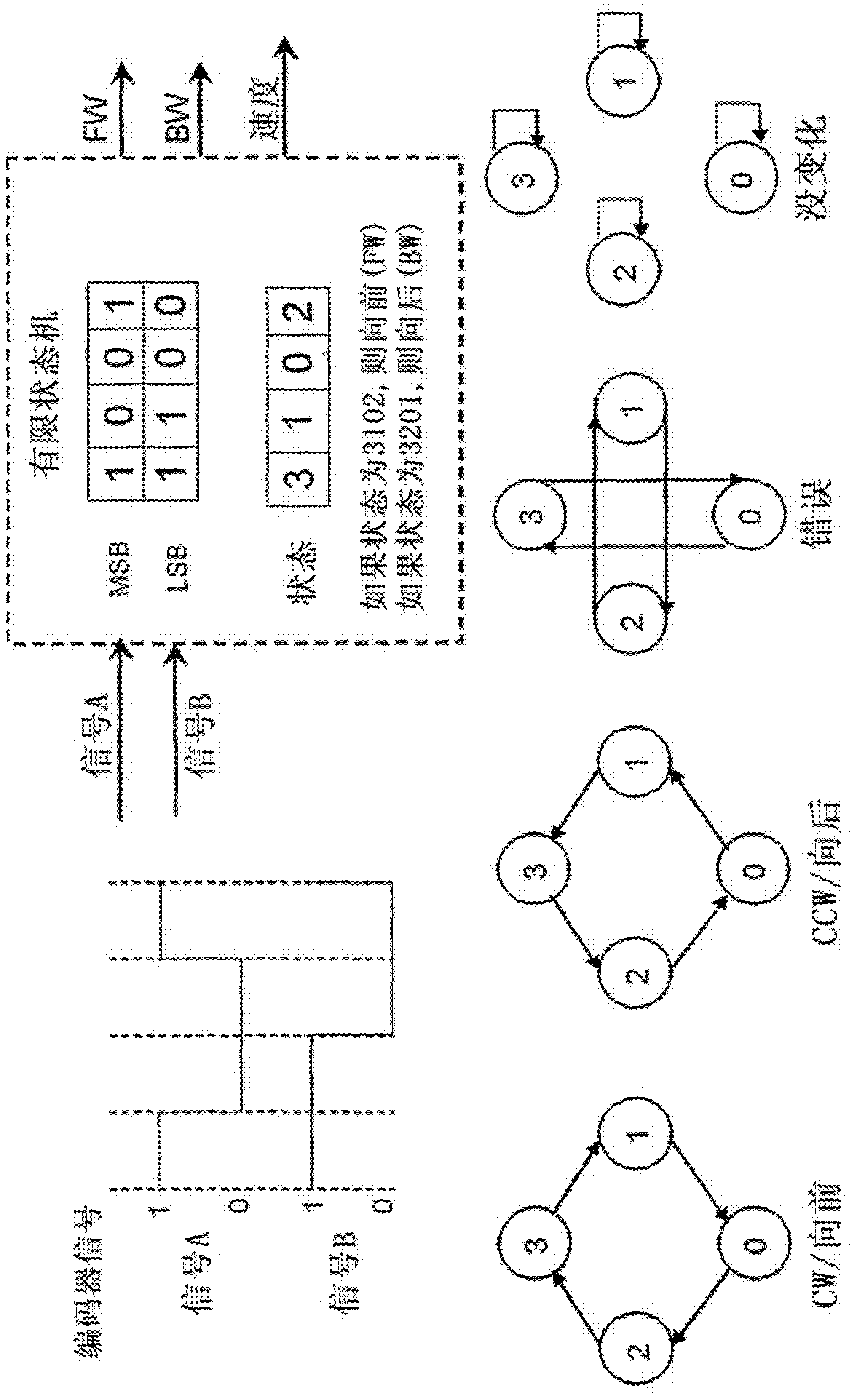

[0039] An example of state transitions and dominant states of an encoder with dual detectors (prior art) has been described in the background of the invention and is given by figure 1 It is shown that the encoder generates double pulses staggered by 90 degrees.

[0040] exist figure 1 In , assign a value to each encoder state, namely the decimal state (3, 1, 0, and 2). If the state transitions to: eg figure 1 3 to 1 to 0 to 2 shown in , then the direction of motion is clockwise (CW), ie forward or upward. If the state transition is reversed (see figure 1 ), the direction of motion is counterclockwise (CCW), that is, backward or downward.

[0041] figure 1 Invalid transitions between different states are also shown in , which can also be used for error detection (prior art). However, the main disadvantage is that there is no error detection based on the current state (only transitions from invalid states) since there is no invalid state in the current state.

[0042] To ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com