Magnetic sensor based on amorphous magnetic core coil and working method thereof

A magnetic sensor and magnetic core technology, applied in the direction of instruments, measuring magnetic variables, measuring devices, etc., can solve the problems of increasing power consumption, affecting the accuracy of measurement, thermal drift, etc., to improve stability and accuracy, improve accuracy, The effect of reducing distractions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

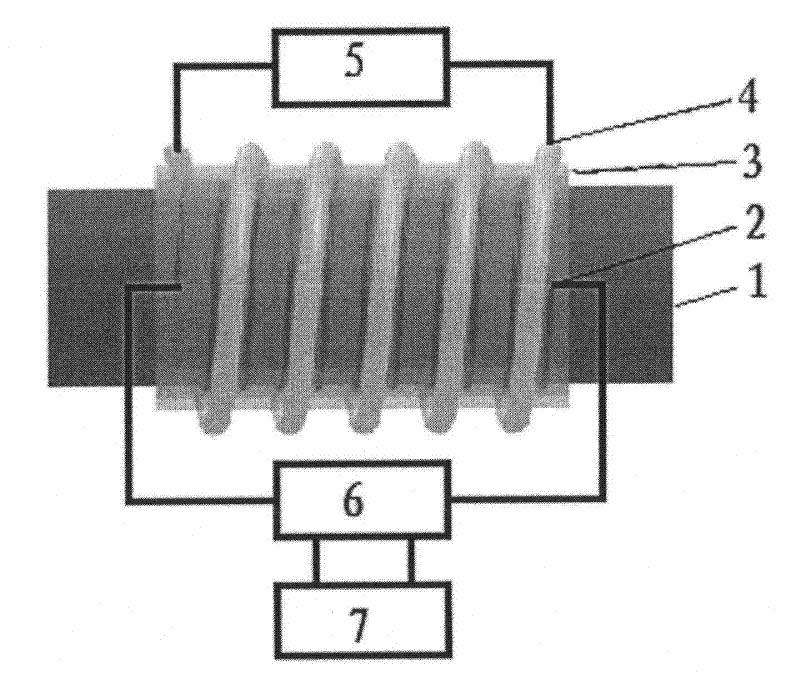

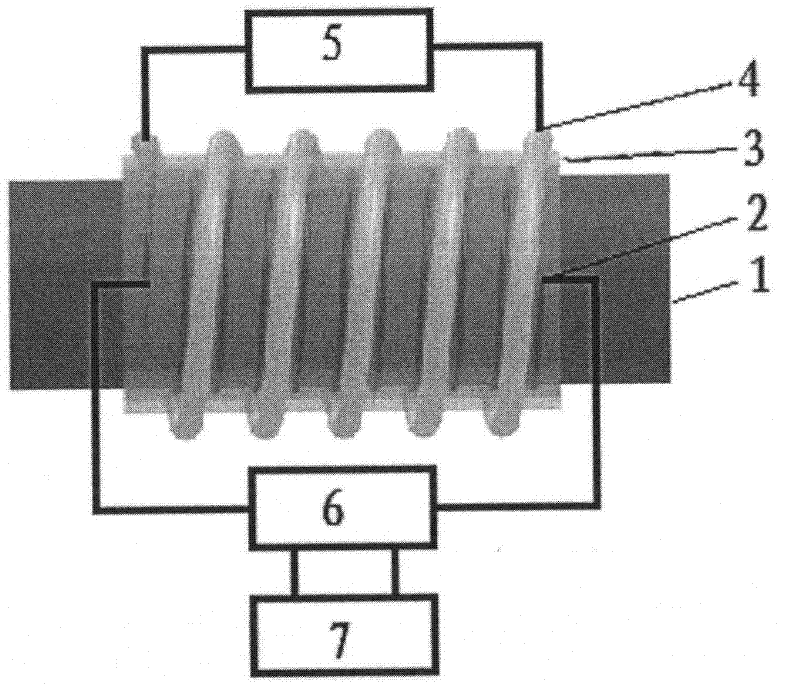

[0020] see figure 1 , the magnetic sensor based on the amorphous magnetic core coil is composed of the magnetic sensitive element of the amorphous magnetic core and the working circuit. in,

[0021] Amorphous magnetic core magnetic sensitive element is a bulk magnetic core 1 composed of laminated sheet-shaped amorphous materials, and an inductance coil 2, an insulating layer 3 and a bias coil 4 are placed outside in sequence; the amorphous material is a cobalt-based amorphous material (or nickel-based amorphous material or iron-based amorphous material), the sheet-shaped amorphous material has a length of 20 mm, a thickness of 0.1 mm, and a width of 6 mm. The block length of the block magnetic core 1 is 20 mm, and the block width is 10mm, and the block height is 10mm.

[0022] The working circuit is composed of a bias circuit 5, an oscillating circuit 6 and a frequency measuring circuit 7; the inductance coil 2 is the inductance coil in the oscillating circuit 6; the oscilla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com