High-power inverter system

An inverter and high-power technology, applied in the field of high-power inverter systems, can solve problems such as system complexity, achieve the effects of reducing costs, improving system reliability, and simplifying software and hardware control circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

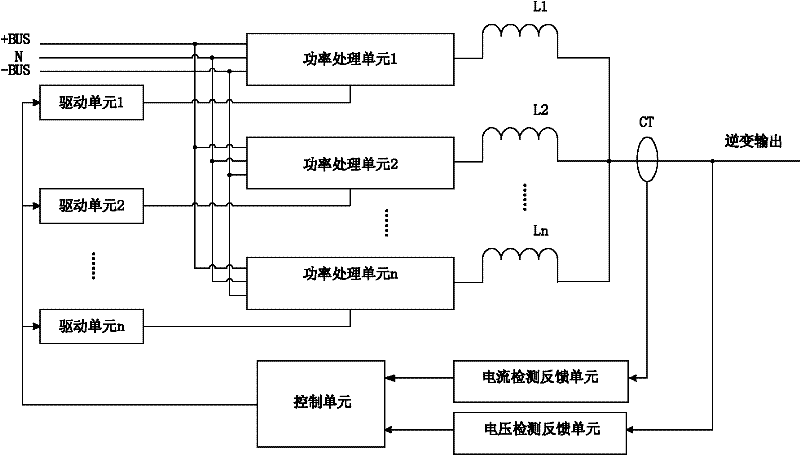

[0034] Figure 4 It is a schematic structural diagram of a high-power inverter system according to Example 1 of the present invention. Such as Figure 4 As shown, the above-mentioned high-power inverter system is a two-branch parallel three-phase inverter system composed of IGBT as the main power device. The system mainly includes: 6 half-bridge arms, high-voltage DC bus, output filter inductor, output filter capacitor, drive circuit, DSP control unit, three-phase current detection feedback unit and three-phase voltage detection feedback unit.

[0035] Among them, each inverter parallel branch (equivalent to the above-mentioned power processing unit) adopts a half-bridge topology, the midpoint of each bridge arm is connected to its own output filter inductor, and each two branches are directly connected in parallel after the output filter inductor as a Phase output; 6 bridge arms are connected in parallel to realize three-phase output.

[0036] After the output filter induc...

example 2

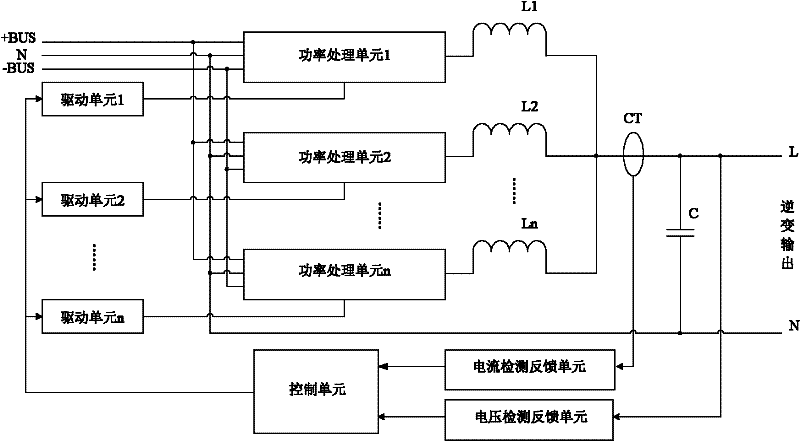

[0039] Figure 5It is a schematic structural diagram of a high-power inverter system according to Example 2 of the present invention. Such as Figure 5 As shown, the above-mentioned high-power inverter system is a three-branch parallel single-phase high-power inverter system composed of power MOSFETs and fast recovery diodes. The system mainly includes: 3 inverter parallel branches and peripheral high-voltage DC input unit, DSP control unit, drive unit, sampling unit, and LC filter unit.

[0040] Among them, each inverter parallel branch (equivalent to the above-mentioned power processing unit) is a diode-clamped three-level inverter circuit. Taking branch 1 as an example, it includes four internal inverters connected in series between the positive and negative bus bars. Power MOS transistors VT1, VT2, VT3, VT4 of parallel diodes; and clamping diodes VD1, VD2 connected between the MOS transistors and the neutral point. The MOS tube and the clamping diode can be in the form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com