Method of reducing the viscosity of hydrocarbon fluids

A hydrocarbon fluid, apparent viscosity technology, used in chemical instruments and methods, drilling compositions, etc., can solve problems such as difficulty in obtaining, pump equipment fatigue, low fluid flow production rate, etc., to improve oil-water separation, reduce equipment Loss, the effect of increasing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

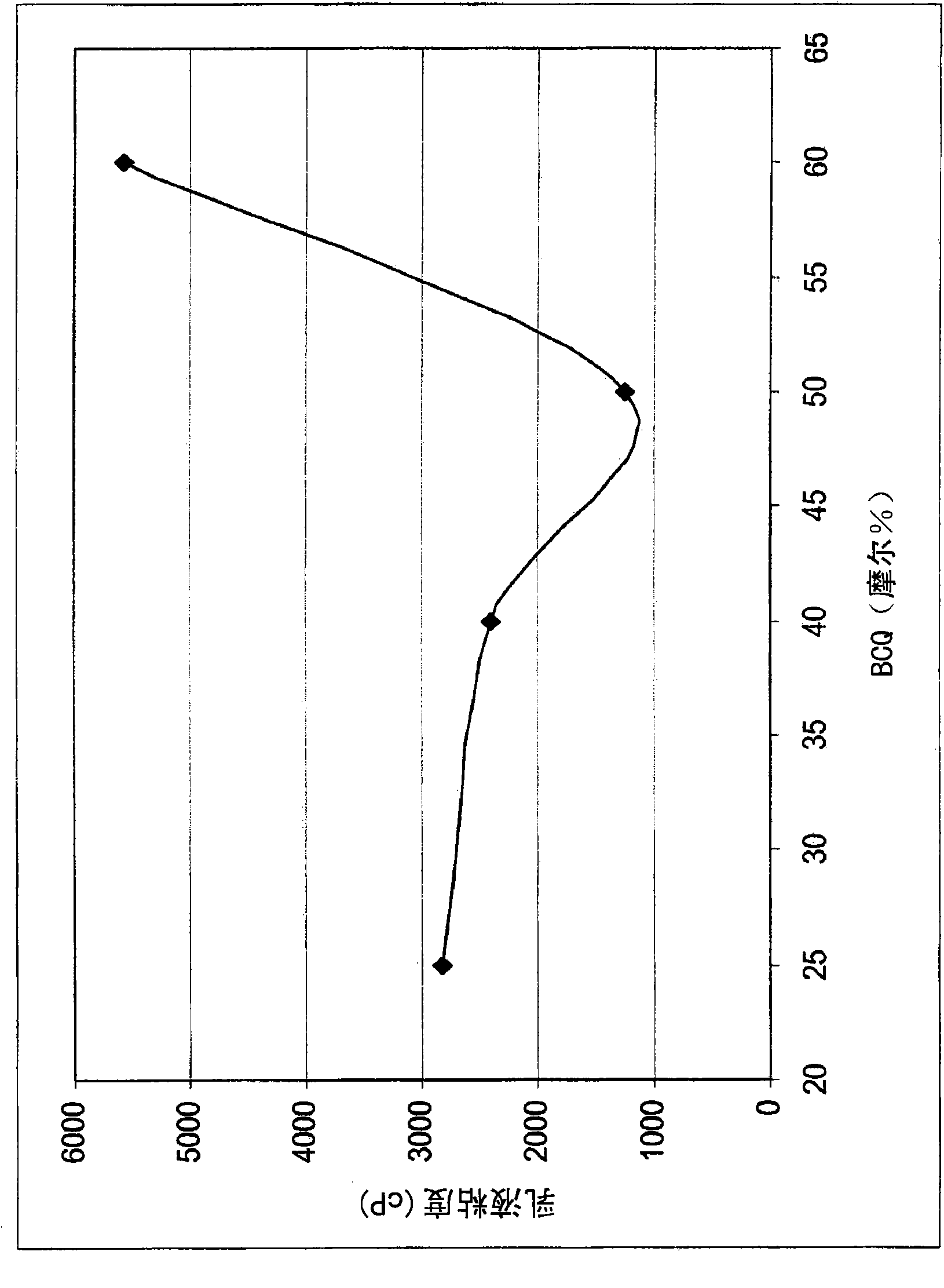

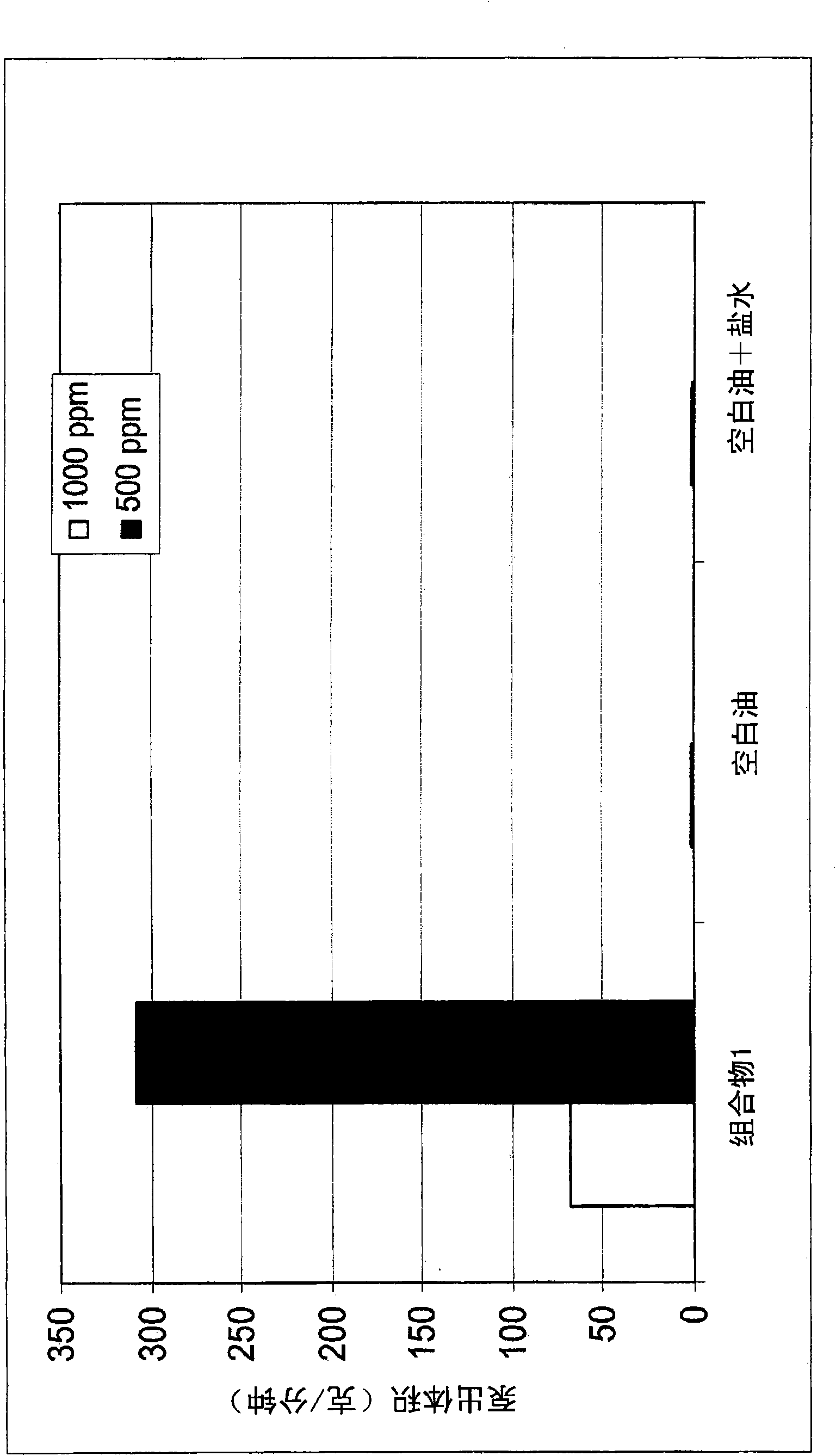

[0056] As an initial screen, two different polymer compositions were analyzed to determine their ability to reduce the apparent viscosity of crude oil at different concentrations. It was found that the use of acrylamide (Acam), N,N-dimethylaminoethylacrylate-benzyl chloride quat (DMAEA-BCQ) and N,N-dimethylaminoethylacrylate The cationic polymer material (composition 1) composed of ester-methyl chloride quaternary salt (DMAEA-MCQ) can significantly reduce the viscosity under a certain range of dosage and water content conditions. Data collected using Composition 1 (11:61:28 Acam:DMAEA-BCQ:DMAEA-MCQ) showed a viscosity reduction of over 80% and showed a dynamic range of water content for viscosity reduction (see Table 1).

[0057] Table 1

[0058]

Embodiment 2

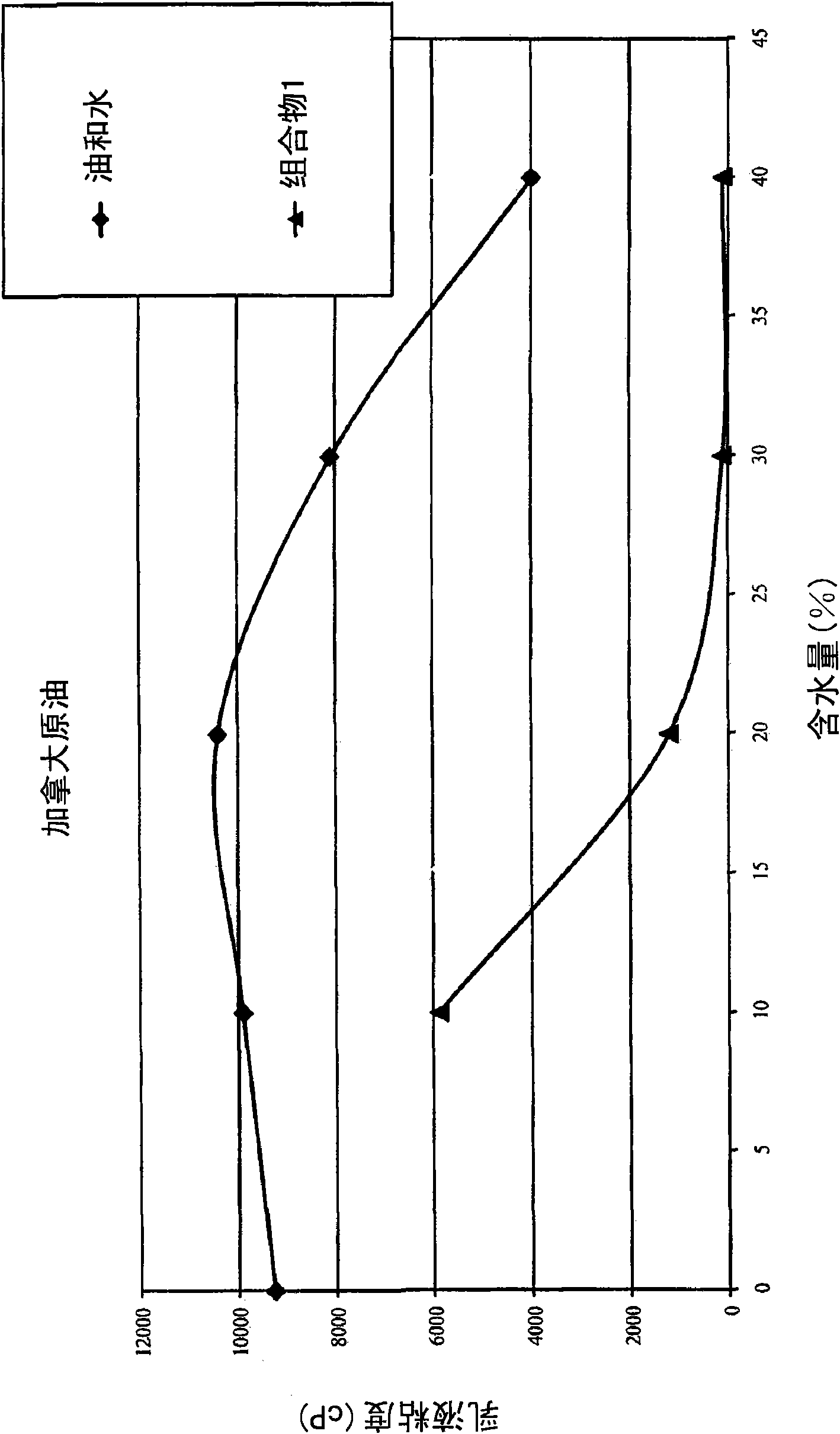

[0060] This example demonstrates the effectiveness of the invention in reducing viscosity based on the amount of water added to the crude oil, which is limited to a minimum of 10% water in order to maintain a significantly lower viscosity emulsion that flows easily (see figure 1 ).

Embodiment 3

[0062] The high molecular weight cationic polymers of Composition 1 provide a unique class of W ) is 5,000,000-15,000,000kD - using type M W =∑(N i m i 2 ) / ∑(N i m i ) calculation, where N i = number of molecules of this molecular weight, M i = molecular weight of the molecule) high cationic charge density polymers of quaternary amines such as methyl chloride and benzyl chloride. Additional studies using similar lower molecular weight (less than 100,000 kD) charged polymers demonstrated that molecular weight has a significant effect on the performance of the charged material and its ability to emulsify (see Table 2). It should be noted that the viscosity increases with time and the amount of water decreases over time, making the emulsion unstable.

[0063]In Table 2, the chemical numbers are as follows: Composition 2 is 50 / 50 Acam / DMAEA-BCQ; Composition 3 is 50 / 50 Acam / DMAEA-BCQ; Composition 4 is 50 / 25 / 25 Acam / DMAEA- BCQ / DMAEA-MCQ; Composition 5 was 25 / 75 Acam DMAEA-B...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com