Catalytic cracking method and device thereof

A catalytic cracking device and catalytic cracking technology, which is applied in the fields of refining and cracking process treatment, petroleum industry, hydrocarbon oil treatment, etc., can solve the problems of difficulty in significantly improving catalyst performance, difficulty in termination control, and impact on economy, etc. , to achieve the effect of enhancing catalytic reaction selectivity, ensuring reactivity, and making simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

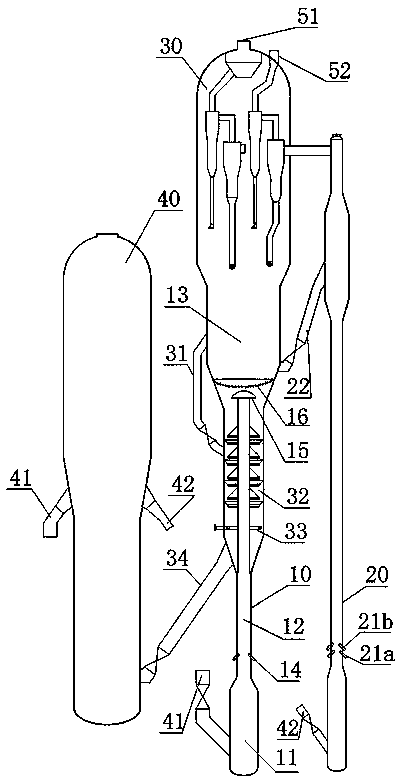

[0046] The design of a catalytic cracking unit in an oil refinery is as follows: figure 1 As shown, the first reaction zone 12 of the main reactor has a diameter of 1.4m, and the second reaction zone 13 has a bed diameter of 7.2m; the secondary reactor 20 is a riser reactor with a diameter of 0.9m; the catalyst return pipe 31 adopts an external circulation pipe; , Secondary reactor oil gas is drawn respectively by oil gas outlet 51,52 and handles separately; Reaction process is as follows:

[0047] The heavy oil preheated at 220°C is atomized through the nozzle 14, enters the riser of the first reaction zone 11 of the main reactor 10, and is mixed with the regenerated catalyst to gasify, then flows upwards along the first reaction zone 11, and reacts continuously, the reaction temperature 520°C, reaction time 1.0s, after the reaction is completed, the mixture is separated from the catalyst through the splitter 15, and the oil and gas enter the fluidized bed of the second reac...

Embodiment 2

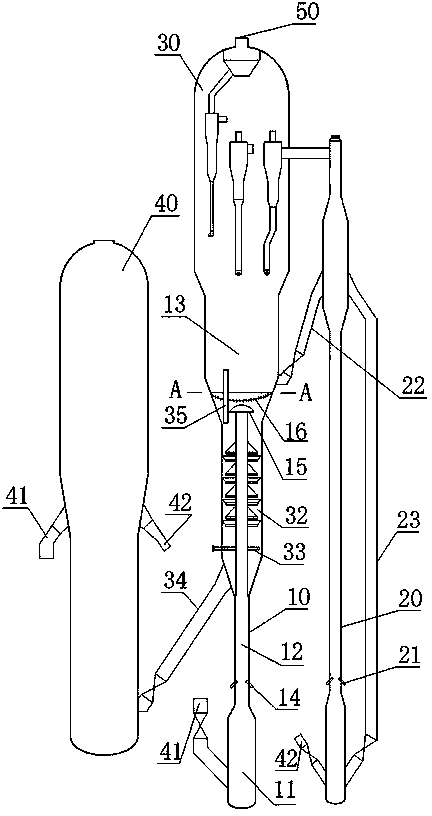

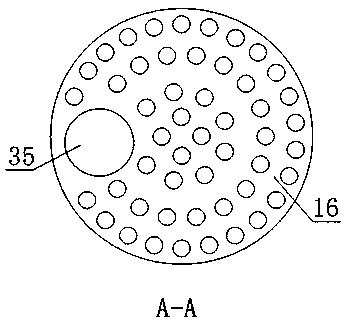

[0050] Such as figure 2 As shown, the catalyst return pipe 35 adopts the form of an inner overflow pipe; the catalyst return pipe 23 is arranged between the middle part and the bottom of the secondary reactor 20; the main and secondary reactors are mixed with oil and gas, and are drawn out from the common outlet 50; the rest of the device structure is the same as figure 1 . During the reaction process of the secondary reactor 20, 20% spent catalyst is introduced into the bottom of the reactor 20 through the catalyst return pipe 22, so as to reduce the thermal cracking process of the secondary reactor. In this embodiment, the specific device A-A direction structure of the inner overflow pipe 35 passing through the distribution plate 16 is as follows image 3 shown.

Embodiment 3

[0052] Such as Figure 4 As shown, the outlet of the lower material leg 37 of the front-stage gas-solid cyclone of the two-stage gas-solid cyclone of the secondary reactor 20 directly extends into the fluidized bed of the second reaction zone 13, thereby introducing into the second reaction zone Standing catalyst. The rest of the device structure is the same as figure 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com