A kind of catalyst for synthesizing 3,5-dichloroaniline and its preparation method and application

A technology of dichloroaniline and catalyst, which is applied in the field of catalyst for the synthesis of 3,5-dichloroaniline and its preparation, which can solve the problems of serious environmental pollution, reduced reaction rate, and low dechlorination rate, and achieve high catalytic activity and adsorption Strong ability and low dechlorination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

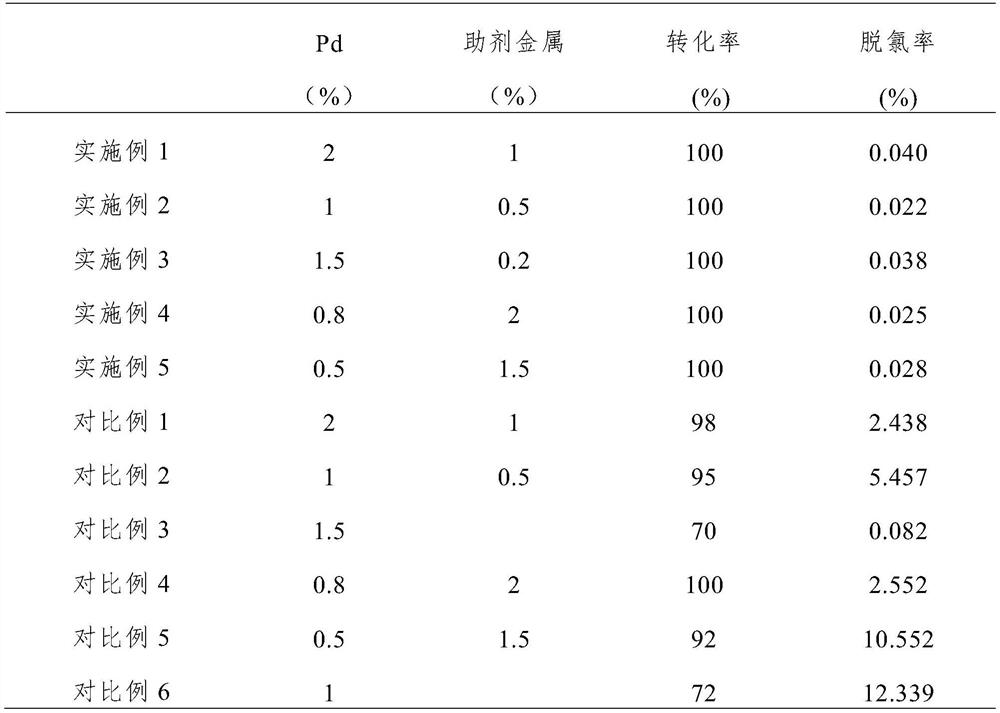

Examples

Embodiment 1

[0030] The catalyst for synthesizing 3,5-dichloroaniline in this embodiment includes a barium sulfate carrier, Pd and auxiliary metals supported on the barium sulfate carrier, and the mass percentage of Pd in the catalyst is 2.0%, The mass percentage of auxiliary metal is 1.0%, and the auxiliary metal is Mn.

[0031] The preparation method of the catalyst for synthesizing 3,5-dichloroaniline of the present embodiment comprises the following steps:

[0032] Step 1. Add 50 g of barium sulfate carrier to 500 mL of boric acid solution with a mass percentage of 2%, stir and reflux in a water bath at 80°C for 3 hours, filter, wash the retentate, and place the washed retentate in a 100°C oven for vacuum drying After 24 hours, it was added to 250 mL of sodium phosphite solution with a mass percentage of 5%, stirred at room temperature for 24 hours, filtered, washed, and vacuum-dried in a 100°C oven for 24 hours to obtain pretreated barium sulfate;

[0033] Step 2, mixing and beatin...

Embodiment 2

[0036]The catalyst for synthesizing 3,5-dichloroaniline in this embodiment includes a barium sulfate carrier, Pd and auxiliary metals supported on the barium sulfate carrier, and the mass percentage of Pd in the catalyst is 1.0%, The mass percentage content of the auxiliary metal is 0.5%, and the auxiliary metal is Co.

[0037] The preparation method of the catalyst for synthesizing 3,5-dichloroaniline of the present embodiment comprises the following steps:

[0038] Step 1. Add 50 g of barium sulfate carrier to 500 mL of boric acid solution with a mass percentage of 15%, stir and reflux in a 100°C water bath for 5 hours, filter, wash the retentate, and place the washed retentate in a 100°C oven for vacuum drying After 24 hours, it was added to 250 mL of sodium phosphite solution with a mass percentage of 10%, stirred at room temperature for 20 hours, filtered, washed, and vacuum-dried in a 100°C oven for 24 hours to obtain pretreated barium sulfate;

[0039] Step 2, mixing...

Embodiment 3

[0042] The catalyst for synthesizing 3,5-dichloroaniline in this embodiment includes a barium sulfate carrier, Pd and auxiliary metals supported on the barium sulfate carrier, and the mass percentage of Pd in the catalyst is 1.5%, The mass percentage content of the auxiliary metal is 0.2%, and the auxiliary metal is Cu.

[0043] The preparation method of the catalyst for synthesizing 3,5-dichloroaniline of the present embodiment comprises the following steps:

[0044] Step 1. Add 50 g of barium sulfate carrier to 500 mL of boric acid solution with a mass percentage of 25%, stir and reflux in a 100°C water bath for 5 hours, filter, wash the retentate, and place the washed retentate in a 100°C oven for vacuum drying After 24 hours, it was added to 250 mL of sodium phosphite solution with a mass percentage of 20%, stirred at room temperature for 20 hours, filtered, washed, and vacuum-dried in a 100°C oven for 24 hours to obtain pretreated barium sulfate;

[0045] Step 2, mixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com