Optical proximity correction method of covered shape

A technology of optical proximity effect and topography, which is applied in the photo-engraving process of optics, pattern surface, and originals for opto-mechanical processing, etc. The actual value of the size becomes smaller, etc., to achieve the effect of improving the coverage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Such as image 3 As shown, the flow chart of the method for correcting the optical proximity effect of the coverage topography of the present invention is shown. The method for correcting the optical proximity effect of the overlay topography according to the embodiment of the present invention includes the following steps:

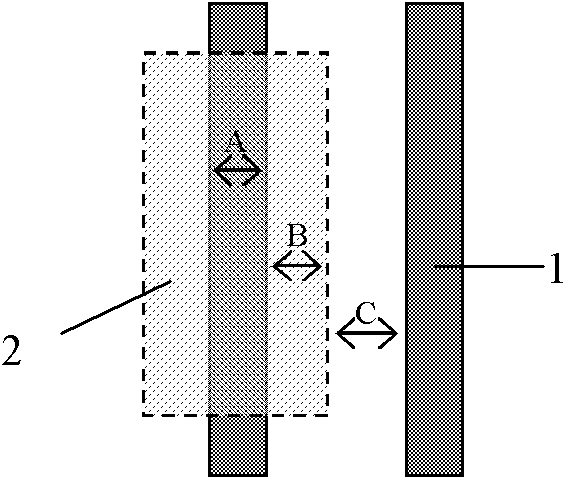

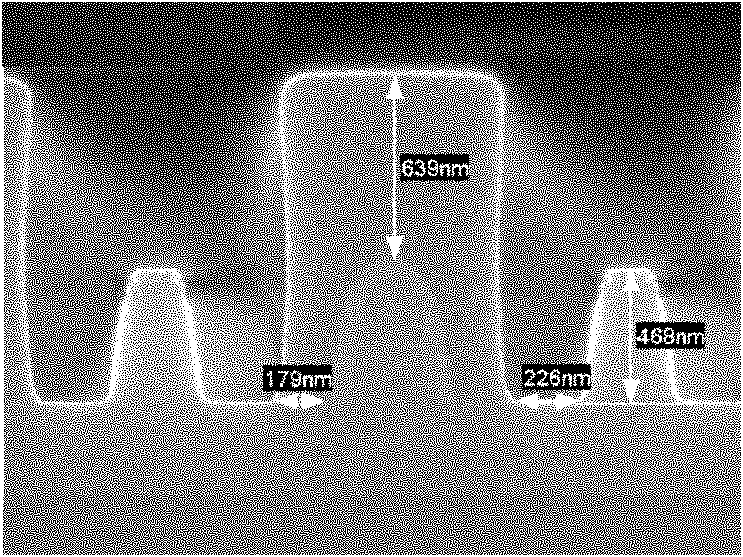

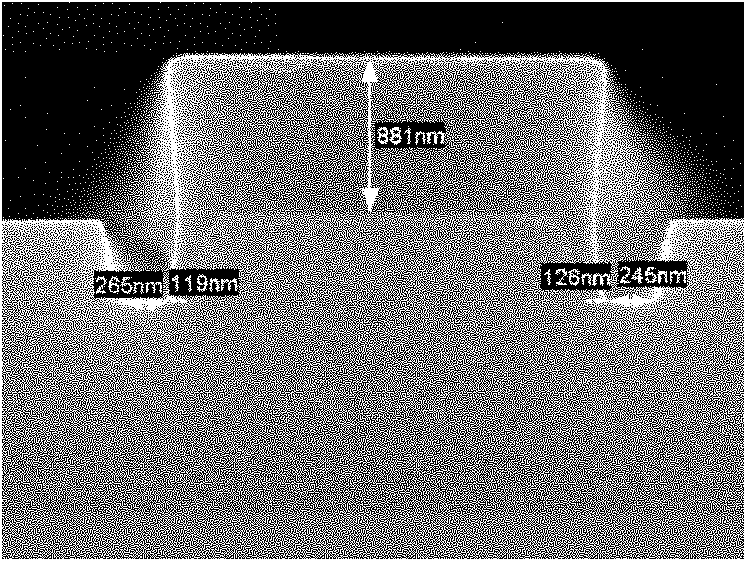

[0022] Step 1, such as figure 1 As shown, a group of test patterns are designed according to the existing optical proximity effect correction method, including the design on the front layer mask, the design on the current layer mask, and the interaction between the design on the current layer mask and the design on the front layer mask. Overlap; through the design on the front mask plate, the front layer etching pattern is formed on the flat sheet, that is, only different film layers, but no lower layer graphics, through the design on the current layer mask plate, the The design on the mask plate of the current layer and the design on the mask pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com