Factory seedling-culturing method for dwarf bamboos

A kind of industrialized ground cover bamboo technology, applied in botany equipment and methods, horticulture, application, etc., can solve the problems of low efficiency and high cost of ground cover bamboo seedlings, achieve good economic benefits and social effects, low cost, and high seedling growth high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Ground cover bamboo industrialized seedling raising method is as follows:

[0016] Choose a flat area that is windy, sunny, convenient for transportation, and convenient for irrigation and drainage, and excavate 6 to 8 drainage ditches with a width of 30 cm and a depth of 50 cm around the seedlings and the interior to form a "field" structure to ensure smooth drainage and achieve seedlings. In the event of heavy rainfall, there should be no water accumulation in the venue.

[0017] Select loose and fertile, deep soil, rich in organic matter, and mountainous yellow soil with a pH value between 4.5 and 7.0 for soil mining. Use a hoe to sort out the fresh soil samples, and through sorting, the soil can meet the requirements of fineness and softness. Put the peat soil and the collected yellow loam into a large mixer according to different volumes, depending on different bamboo species, and add KMnO 4 Carbendazim solution, etc. are used for soil insecticidal disinfection, ...

Embodiment 2

[0022] With reference to the industrialized seedling raising method of ground cover bamboo in Example 1, the effects of emerald green bamboo seedling raising under different substrate ratios (volume ratio, the same below) were compared, and the results are shown in Table 1. It can be seen from Table 1 that under the conditions of different substrate ratios of emerald bamboos, the ratio of peat soil: loess = 1:3, the number of emerald bamboos is the largest, reaching 20, and the rate of emerald bamboos can reach 55.56%. Followed by 1:1 ratio.

[0023] Table 1 The ratio of different substrates to the growth rate of emerald bamboo seedlings

[0024] Matrix ratio

Germination number

Germination rate

Number of withdrawn bamboo shoots

Bamboo number

success rate

1∶1

104

45

43.27%

28

62.22%

17

37.78%

1∶2

104

36

34.62%

23 ...

Embodiment 3

[0042] Material: Phyllostachys spp., a dwarf bamboo species, with a culm height of 0.2-0.8m, a diameter of 0.1-0.2cm, cylindrical internodes, and a flat culm ring. 5 branches per node. Culm sheaths persistent, glabrous. Each twig has 4-7 leaves, the sheath is glabrous, and the mouth of the sheath has white hairs; the leaves are small, lanceolate, 6-15cm long, 0.8-1.4cm wide, except for two white pilose, the back is denser. The leaves are green with distinct white or yellowish stripes. The bamboo shoot period is from April to May. Ornamental garden or potted plants. Distribution: Native to Japan. Introduced and cultivated in Jiangsu, Zhejiang and Shanghai.

[0043] Method: with reference to embodiment 2.

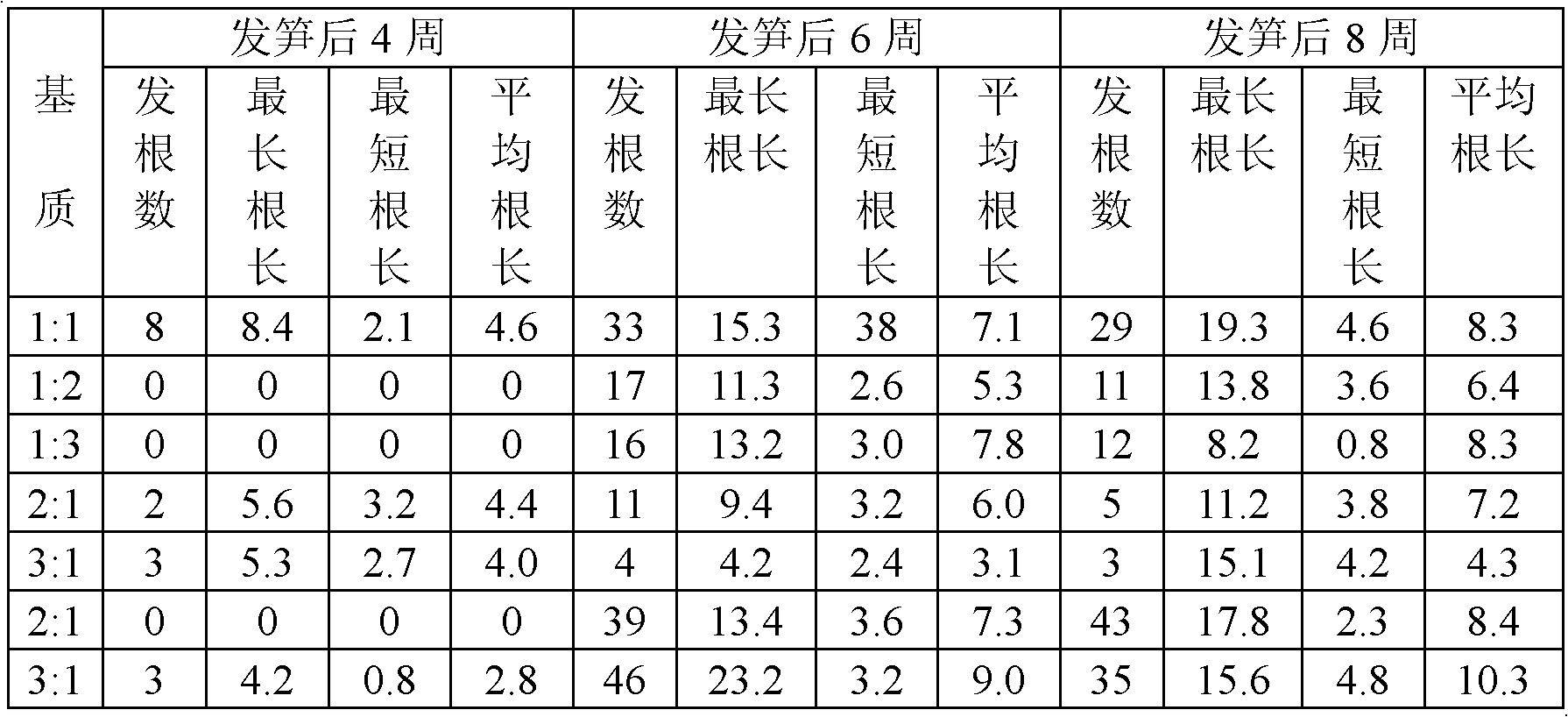

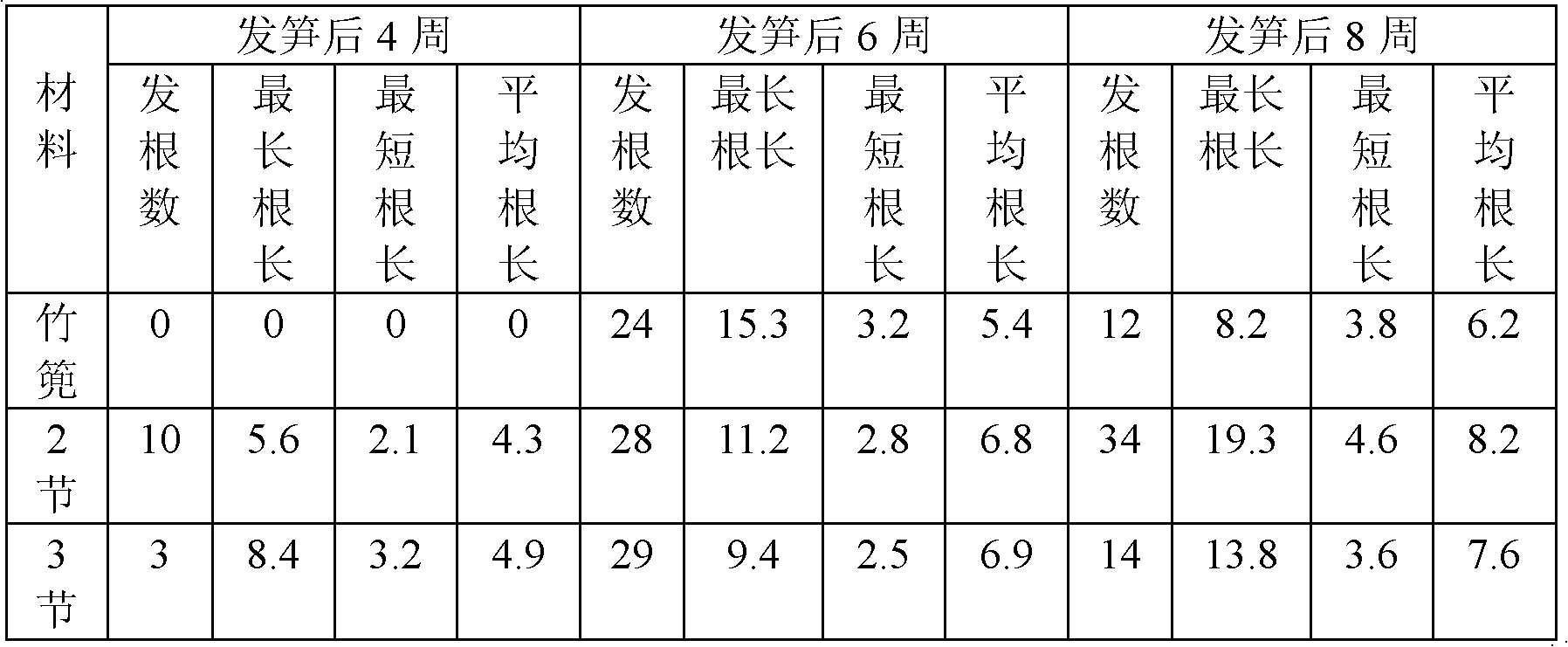

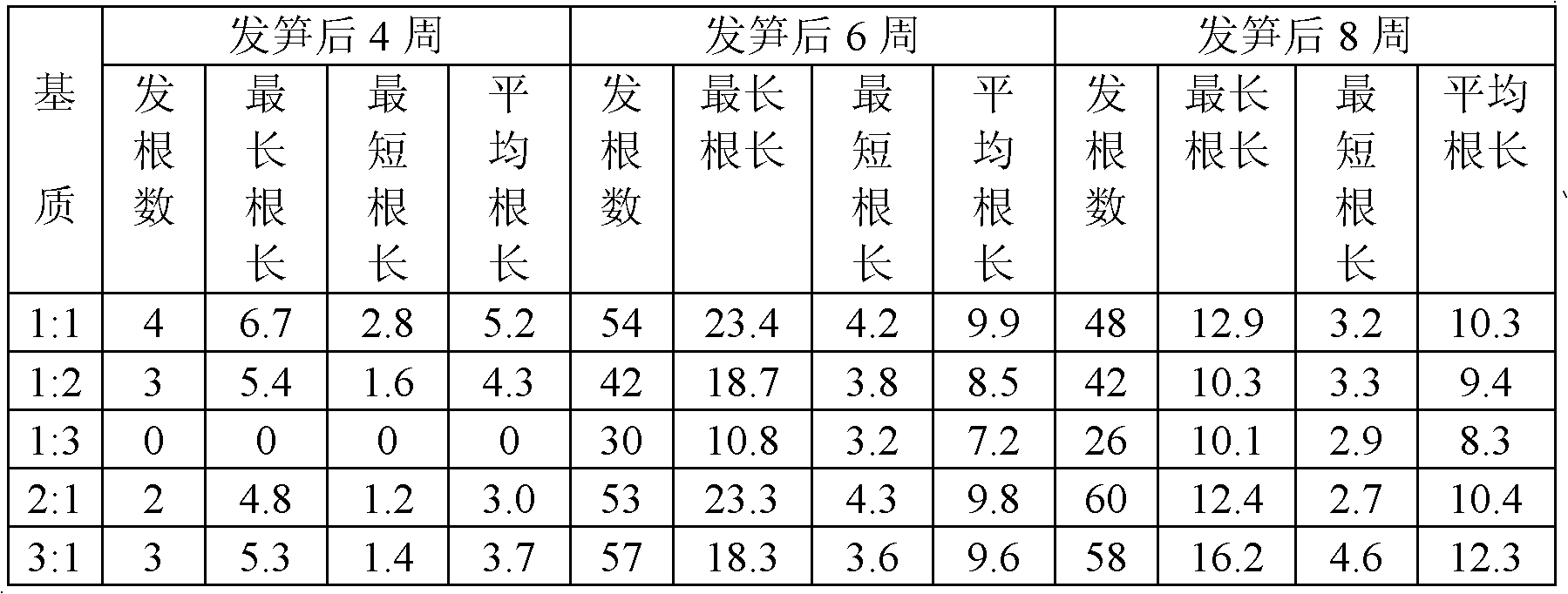

[0044] (1) The effect of different substrate ratios on the rate of bamboo growth of Phyllostachys phenanthae seedlings, the results are shown in Table 7. It can be seen from Table 7 that in the case of different substrate ratios, peat soil: loess = 3:1, the number of m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average root length | aaaaa | aaaaa |

| Average root length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com