Method for processing fireproof flame retardant bamboo, wood, hemp and grass and curtain made of fireproof flame retardant bamboo, wood, hemp and grass

A processing method, a fire-proof and flame-retardant technology, which is applied to wood processing equipment, curtains, tents, etc., can solve the problems of poor flame-retardant performance of bamboo, and achieve the effects of bright coloring, improved flame-retardant performance, and improved durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

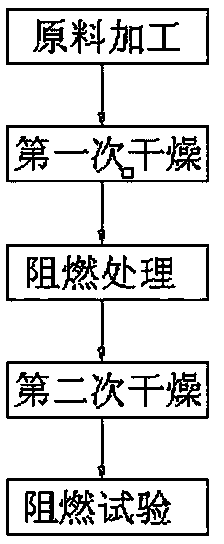

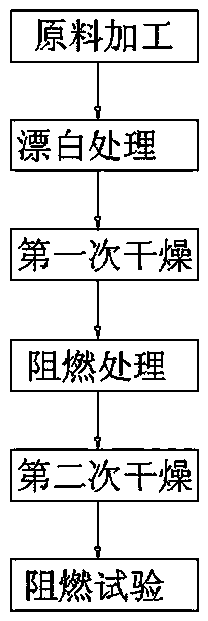

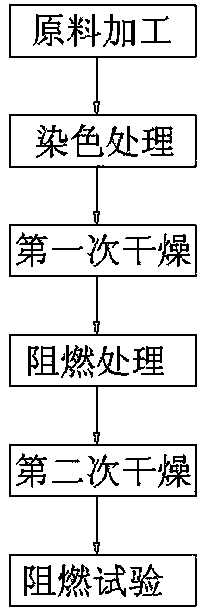

[0027] see Figure 1-Figure 4 , the present invention a kind of processing method of fireproof flame retardant bamboo wood, it is characterized in that, comprises the following steps:

[0028] 1. First process the raw material into a filamentous structure, and the processed size meets the size of the curtain processing. For example, the size and length of bamboo pieces are 160, 190, 260 or 320mm, and the width and thickness are 6mm×1.2mm, 7mm×1.8mm, 12mm× 1.8mm, the length of bamboo filaments is 130mm, 160mm, 190mm, 260mm, 320mm, the diameter of bamboo filaments is 2.5, 1.8 or 1.2mm, and the width of wooden louvers is 2.5-5mm. These dimensions are determined according to the size of the curtain, generally according to the thickness and width of the curtain, taking into account the width of the bamboo to form various stripes; the material can also be wood, grass (rope) or hemp.

[0029] 2. Bleaching treatment (this step can also be omitted for materials with very white texture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com