Ozonated water treatment method with nano ceria as catalyst

A nano-ceria, ozonated water technology, applied in the direction of oxidized water/sewage treatment, etc., can solve the problems of backward development and utilization technology, and achieve the effects of accelerated degradation rate, improved mineralization, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

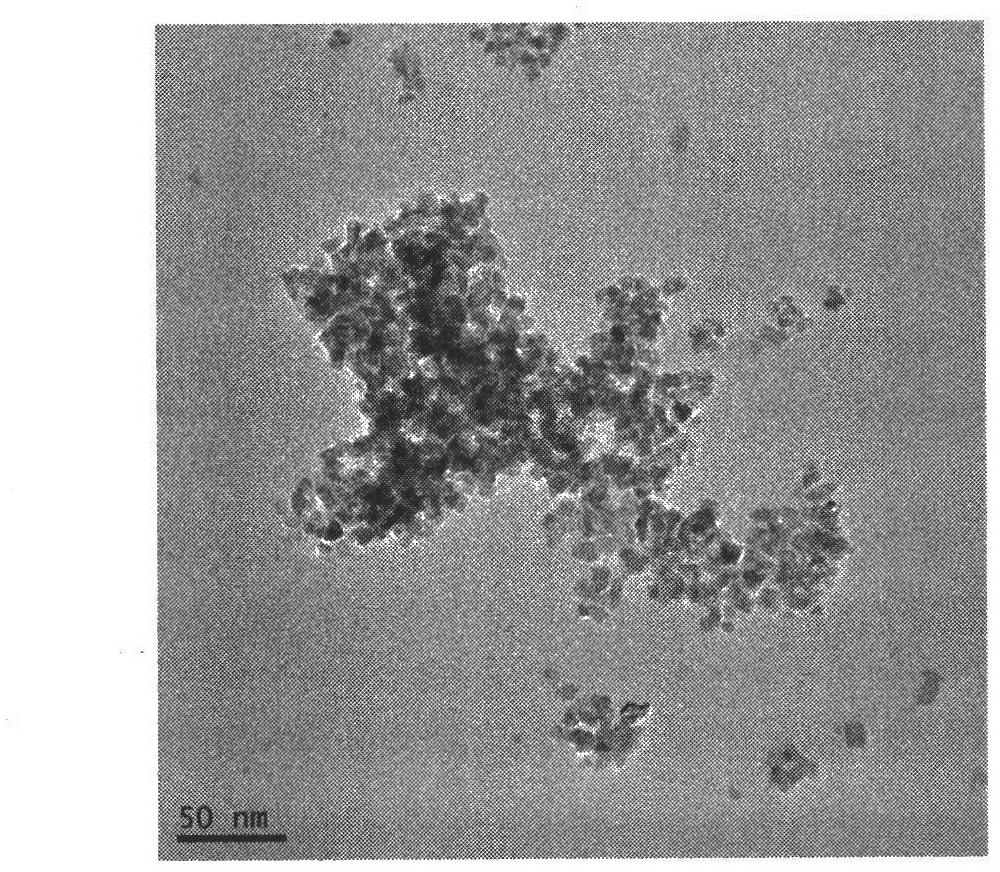

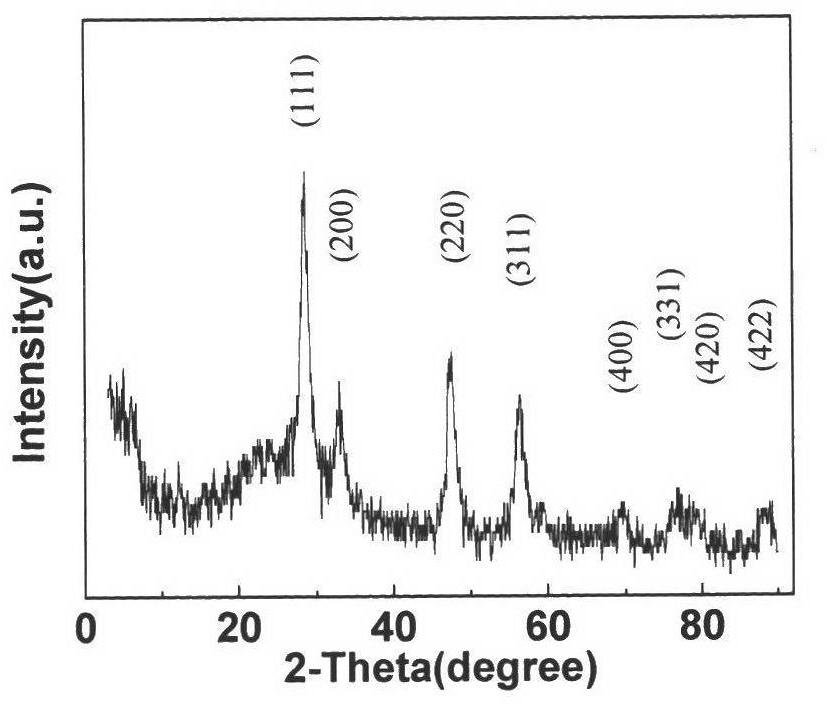

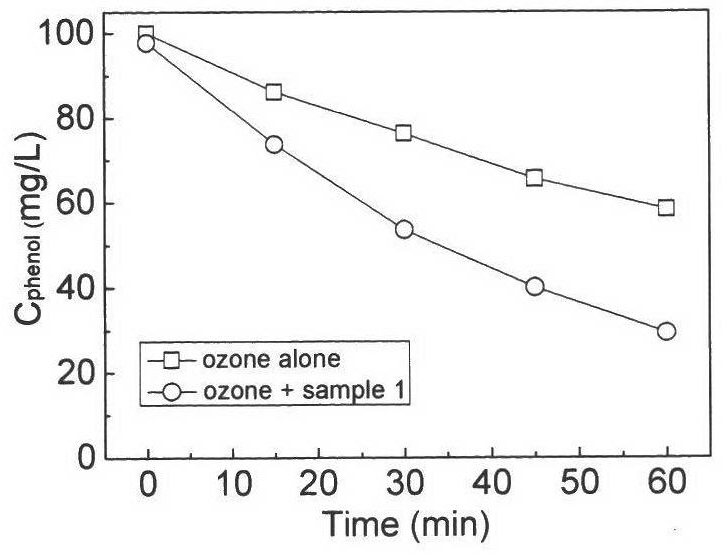

[0021] Weigh 6.01g Ce(NO 3 ) 3 ·6H 2 Dissolve O in 40ml of deionized water (clear and transparent solution), weigh 9.62g of NaOH, and dissolve it in 80ml of deionized water to obtain a 3mol / L NaOH solution. Quickly add the NaOH solution to the cerium salt solution while stirring continuously. After 1h After the precipitate was filtered, it was fully washed with deionized water until the pH was close to neutral, and dried in an oven at 100°C for 24 hours. The dried sample was ground, placed in a muffle furnace and calcined at 400°C for 3h to obtain Sample 1. Its TEM picture is shown in figure 1 , indicating that it is a nanoparticle smaller than 10nm; XRD pattern see figure 2 , all the diffraction peaks can be compared with the cubic CeO 2 The peak position of the spectrum (JCPDS Card No.43-1002) matches, indicating that it is CeO 2 ;BET specific surface area is 113m 2 / g.

Embodiment 2

[0023] Weigh 6.01g Ce(NO 3 ) 3 ·6H 2 Dissolve O in 40ml of deionized water (clear and transparent solution), weigh 9.62g of NaOH, and dissolve it in 80ml of deionized water to obtain a 3mol / L NaOH solution. Quickly add the NaOH solution to the cerium salt solution while stirring continuously. After 1h After the precipitate was filtered, it was fully washed with deionized water until the pH was close to neutral, and dried in an oven at 100 ° C for 24 hours, the dried sample was ground, and it was calcined at 300 ° C in a muffle furnace for 3 h to obtain Sample 2.

Embodiment 3

[0025] Weigh 8.60g Ce(NO 3 ) 3 ·6H 2 Dissolve O in 40ml of deionized water (clear and transparent solution), weigh 9.62g of NaOH, and dissolve it in 80ml of deionized water to obtain a 3mol / L NaOH solution. Quickly add the NaOH solution to the cerium salt solution while stirring continuously. After 1h After the precipitate was filtered, it was fully washed with deionized water until the pH was close to neutral, and dried in an oven at 100°C for 24 hours. The dried sample was ground, placed in a muffle furnace and calcined at 400°C for 3h to obtain Sample 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com