Preparation method of heptafluoropropane

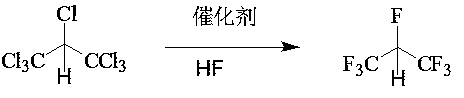

A technology for heptafluoropropane and heptachloropropane, which is applied in the field of heptafluoropropane gas preparation by a method of fluorine and chlorine replacement, can solve the problems of strong corrosion of glassware and precision instruments, restricted places and ranges of use, etc., and achieves low production cost and high production cost. The effect of lowering and lowering prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Heat and vaporize 1,1,1,2,3,3,3-heptachloropropane, then mix 1,1,1,2,3,3,3-heptachloropropane gas with hydrogen fluoride gas (according to the molar ratio of 1: 5) into a fixed-bed reactor equipped with a catalyst (chromium trichloride supported on aluminum oxide, purchased from Nanhua Research Institute), at 30 atmospheres, at a temperature of 230 ° C, the time for passing the catalyst is 9 seconds, 1,1,1,2,3,3,3-heptafluoropropane was separated by rectification, and 1,1,1,2,3,3,3-heptachloropropane was converted into 1,1,1,2 , The single conversion rate of 3,3,3-heptafluoropropane is 46%.

Embodiment 2-9

[0019] Heat and vaporize 1,1,1,2,3,3,3-heptachloropropane, then mix 1,1,1,2,3,3,3-heptachloropropane gas with hydrogen fluoride gas (according to the molar ratio of 1: 5) into a fixed-bed reactor equipped with a catalyst (chromium trichloride supported on aluminum oxide, purchased from Nanhua Research Institute), and rectified to separate 1,1,1,2,3,3, 3-Heptafluoropropane. Wherein reaction temperature, pressure, feed gas pass through catalyst time and gained productive rate are shown in the following table:

[0020] Example 2 3 4 5 6 7 8 9 temperature / ℃ 320 380 230 320 380 230 320 380 pressure / atm 30 30 10 10 10 2 2 2 time / second 9 9 40 22 15 40 15 9 Yield / % 45 47 46 47 48 47 48 46

Embodiment 10

[0022] Heat and vaporize 1,1,1,2,3,3,3-heptachloropropane, then mix 1,1,1,2,3,3,3-heptachloropropane gas with hydrogen fluoride gas (according to the molar ratio of 1: 6) Into a fixed-bed reactor equipped with a catalyst (chromium trifluoride supported on aluminum oxide, purchased from Nanhua Research Institute), at 30 atmospheres, at a temperature of 230°C, the time for passing the catalyst is 9 seconds, 1,1,1,2,3,3,3-heptafluoropropane was separated by rectification, and 1,1,1,2,3,3,3-heptachloropropane was converted into 1,1,1,2 , The single conversion rate of 3,3,3-heptafluoropropane is 47%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com