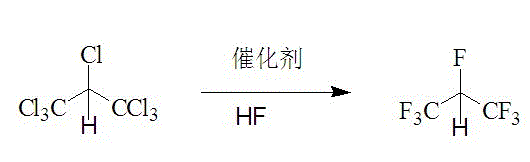

Preparation method for heptafluoropropane through gas phase catalysis fluorination

A technology of heptafluoropropane and heptachloropropane, which is applied in the field of preparing heptafluoropropane gas by a method of fluorine and chlorine replacement, which can solve the problems of restricted places and scope of use, strong corrosion of glassware and precision instruments, etc., and achieve low production costs and lower prices , the effect of simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0022] Activated carbon pretreatment: Pour 150 g of activated carbon particles with a diameter of 2-4mm into 1000 mL of 36.5wt% concentrated hydrochloric acid and 40wt% hydrofluoric acid aqueous solution, stir at room temperature for 24 hours, filter, wash with water until neutral, 120 ℃ for 10 hours, 300 ℃ for 5 hours, and then used as a catalyst carrier.

[0023] 5 g CrCl 3 and 0.5g LaF 3 Dissolve in 50 mL water to make a solution, weigh 44.5 g of the above activated carbon and pour it into CrCl 3 solution, stirred for 3 hours. 120 o C dried for 5 hours and dried at 300°C for 5 hours to obtain 10 wt% CrCl 3 / 1wt%LaF 3 / C catalyst, denoted as Cat-1.

preparation Embodiment 2

[0025] Take 5g Cr 2 o 3 , 0.25g LaF 3 And the activated carbon after the above-mentioned pretreatment of 44.75g, prepare 10wt%Cr in the same way as Example 1 2 o 3 / 0.5wt%LaF 3 / C and recorded as Cat-2, the difference is the use of Cr 2 o 3 Instead of CrCl 3 .

preparation Embodiment 3

[0027] Take 5g CrBr 3 , 0.05g LaF 3 And the activated carbon after the above-mentioned pretreatment of 44.95g, prepare 10wt%CrBr in the same way as Example 1 3 / 0.1wt%LaF 3 / C and denoted as Cat-3, the difference is the use of CrBr 3 Instead of CrCl 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com