Method for preparing paeoniflorin and albiflorin

A technology of paeoniflorin and alba paeoniflorin, which is applied in the field of preparation of paeoniflorin and alba peony, can solve the problems that paeoniflorin and alba paeoniflorin cannot be separated, the operation of column packing and detection is complicated, and it is difficult to realize industrial production. Effects of recovery and recycling, realization of automation and operability, and simplification of process burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

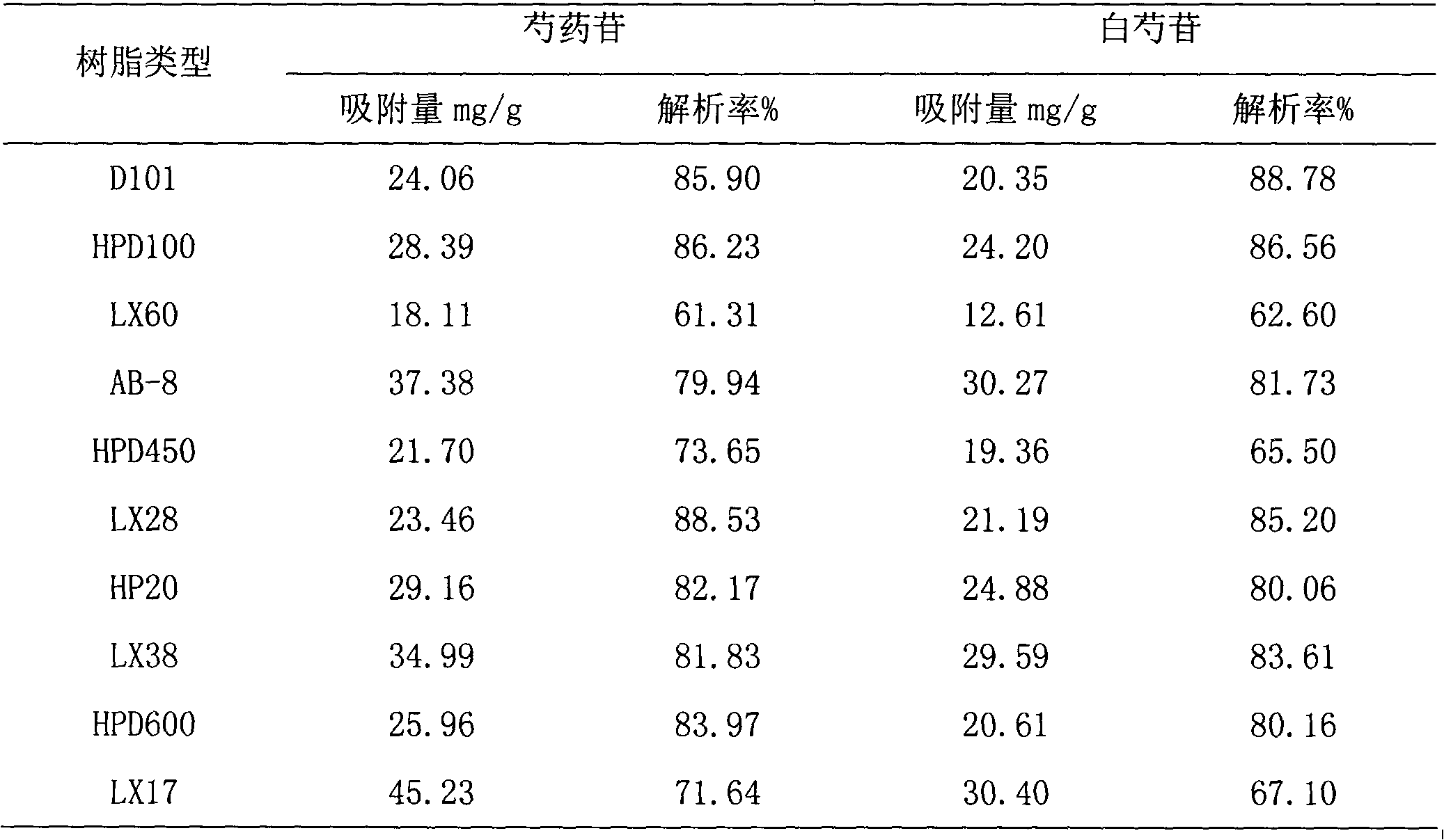

[0016] Embodiment 1 macroporous resin static adsorption performance investigation

[0017] Weigh 1kg Radix Paeoniae Alba decoction pieces, extract twice with 8L of 70% ethanol under reflux, each time for 2h, filter, combine the filtrates, concentrate under reduced pressure until there is no alcohol smell, adjust the medicinal solution so that each 1ml medicinal solution is equivalent to 0.5g crude drug, and set aside.

[0018] Weigh 1.00g of the dry weight of each type of resin, place them in ten 50ml conical flasks with stoppers, add 10ml of Radix Paeoniae Alba extract (0.5g crude drug / ml), shake in a constant temperature shaking box at 35°C for 6h, The vibrating speed was 180prm, and the adsorbed Radix Paeoniae Alba extract was vacuum filtered, and the filtrate was properly diluted, and the contents of Paeony Radix and Radix Paeoniae Alba were determined by HPLC with reference to the method of the 2010 edition of Pharmacopoeia. The adsorbed resin was washed with water for 3 ...

Embodiment 2

[0025] The preparation of embodiment 2 Radix Paeoniae Alba extract

[0026] Weigh 40kg of Radix Paeoniae Alba, soak overnight in 70% ethanol, reflux extraction twice, each time for 2 hours, filter, combine the filtrate, and rotary evaporate until there is no alcohol smell, adjust the liquid so that every 1ml of liquid is equivalent to 0.5g of crude drug, spare. Weigh 120kg (wet weight) of LX38 resin, put it into a stainless steel column (300×2300cm), the column volume is 60L, load the sample, after adsorption for 1h, first remove impurities with 300L of water, 300L of 10% ethanol, and then use 360L of 50% ethanol Elute paeoniflorin and paeoniflorin, and finally regenerate the resin with 95% ethanol at a flow rate of 150-200L / h. Concentrate and evaporate the 50% ethanol part to obtain 2.52kg, wherein the purity of paeoniflorin is 24%, and that of paeoniflorin is 16 %.

Embodiment 3

[0027] The preparation of embodiment 3 Radix Paeoniae Alba extract

[0028] Weigh 40kg Radix Paeoniae Alba decoction pieces, soak overnight with 70% ethanol, reflux extraction twice, each time for 2 hours, filter, combine the filtrate, rotary evaporate to no alcohol smell, adjust the liquid medicine so that every 1ml liquid medicine is equivalent to 0.5g crude drug, spare. Weigh 120kg (wet weight) AB-8 resin, put it into a stainless steel column (300×2300cm), the column volume is 60L, load the sample, after adsorption for 1h, first remove impurities with 300L of water and 300L of 10% ethanol, and then use 50% Elute paeoniflorin and paeoniflorin with 360L of ethanol, and finally regenerate the resin with 95% ethanol at a flow rate of 150-200L / h. Concentrate and evaporate the 50% ethanol part to obtain 2.32kg, wherein the purity of paeoniflorin is 22%, and the purity of paeoniflorin is 22%. 12%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com