Organosilicon-modified styrene-acrylic architectural waterproof latex and preparation method thereof

A technology of building waterproofing and silicone, which is applied in the field of latex for building waterproofing coatings and its preparation. It can solve the problems of poor compatibility, low surface energy, water resistance and air permeability, and achieve improved compatibility, wide distribution, and excellent storage stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

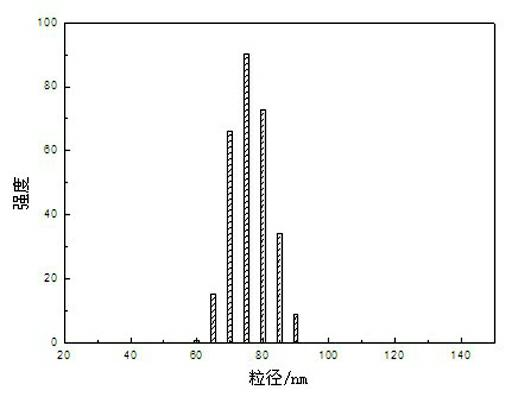

Embodiment 1

[0032] The total amount of emulsifier is 1.2 (wt)% of the system, of which the weight ratio of anion: non-ionic emulsifier is 2:1, and the amount of γ-methacryloxypropyl trimethoxysilane (KH570) is 0.5 (wt) % as an example:

[0033] 1. Weighing:

[0034] Weigh 13.5 kg styrene, 32.7 kg butyl acrylate, 0.7 kg acrylamide, 0.6 kg acrylic acid, 0.3 kg sodium bicarbonate, 0.7 kg sodium dodecylbenzenesulfonate, 0.4 kg nonylphenol polyoxyethylene ether, 0.1 kg propenyl ether sulfonic acid sodium salt, 0.5 kg KH570, 0.5 kg potassium persulfate and 50 kg deionized water.

[0035] And 0.7 kg sodium dodecylbenzene sulfonate, 0.4 kg nonylphenol polyoxyethylene ether, 0.1 kg propenyl ethyl ether sulfonic acid sodium salt are mixed to form 1.2kg emulsifier mixture, and then 1.2 kg emulsifier mixture is divided into Two servings, one is 0.84kg and the other is 0.36kg.

[0036] Divide 0.5 kg of potassium persulfate into three parts, the first part is 0.16kg, the second part is 0.24kg, and t...

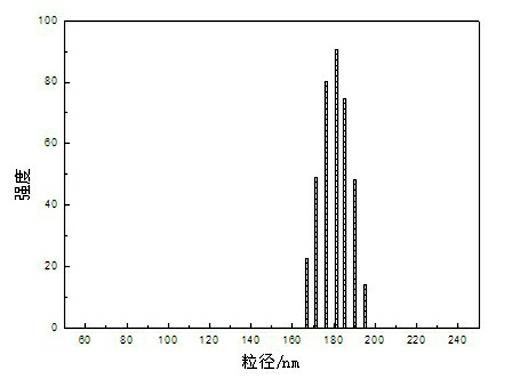

Embodiment 2

[0043] The total amount of emulsifier is 1.2 (wt)% of the system, where the weight ratio of anion: non-ionic emulsifier is 1:2, without KH570 as an example:

[0044] 1. Weighing:

[0045] Styrene 13.5%

[0046] Butyl Acrylate 33.2%

[0047] Acrylamide 0.7%

[0048] Acrylic 0.6%

[0049] Sodium bicarbonate 0.3%

[0050] Sodium dodecylbenzenesulfonate 0.3%

[0051] Nonylphenol ethoxylate 0.8%

[0052] Sodium propenyl ether sulfonate 0.1%

[0053] Potassium persulfate 0.5%

[0054] Deionized water 50%

[0055] 2. Preparation process:

[0056] 1. Add 70% emulsifier, deionized water, styrene, butyl acrylate, pH regulator, and functional monomer into the emulsifier for pre-emulsification at room temperature to obtain a pre-emulsion;

[0057] 2. In the stirred polymerization reactor, add the remaining emulsifier and water, 20% of the pre-emulsion and 50% of the initiator solution in step (1), and add the reaction system water bath to 70±1°C until the blue light appears in the...

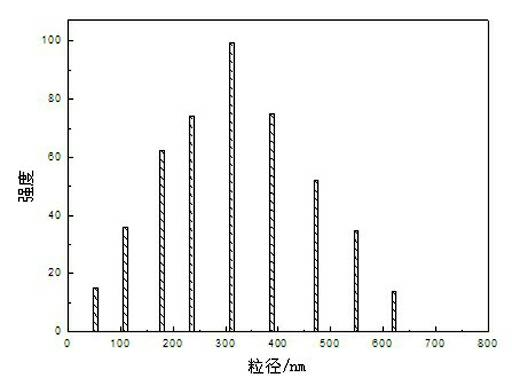

Embodiment 3

[0061] The total emulsifier dosage is 1.2 (wt)% of the system, where the anion: nonionic emulsifier weight ratio is 1:2, and the KH570 dosage is 0.5 (wt)% as an example:

[0062] 1. Weighing:

[0063] Styrene 13.5%

[0064] Butyl Acrylate 32.7%

[0065] Acrylamide 0.7%

[0066] Acrylic 0.6%

[0067] Sodium bicarbonate 0.3%

[0068] Sodium dodecylbenzenesulfonate 0.3%

[0069] Nonylphenol ethoxylate 0.8%

[0070] Sodium propenyl ether sulfonate 0.1%

[0071] γ-Methacryloxypropyltrimethoxysilane 0.5%

[0072] Potassium persulfate 0.5%

[0073] Deionized water 50%

[0074] 2. Preparation process:

[0075] 1. Add 70% emulsifier, deionized water, styrene, butyl acrylate, pH regulator, and functional monomer into the emulsifier for pre-emulsification at room temperature to obtain a pre-emulsion;

[0076] 2. In the stirred polymerization reactor, add the remaining emulsifier and water, 20% of the pre-emulsion and 50% of the initiator solution in step (1), and add the react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap