Transparent cold resistance high melt-strength polypropylene material used for automobile expansion water tank and its preparation method

A high-melt-strength, polypropylene material technology, applied in the field of polypropylene material modification, can solve the problems of not being able to meet the needs of automobile expansion tanks, complex equipment and production steps, and insufficient low-temperature toughness, etc., and achieve low damage rate and melt Strength Transparency and easy blow molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

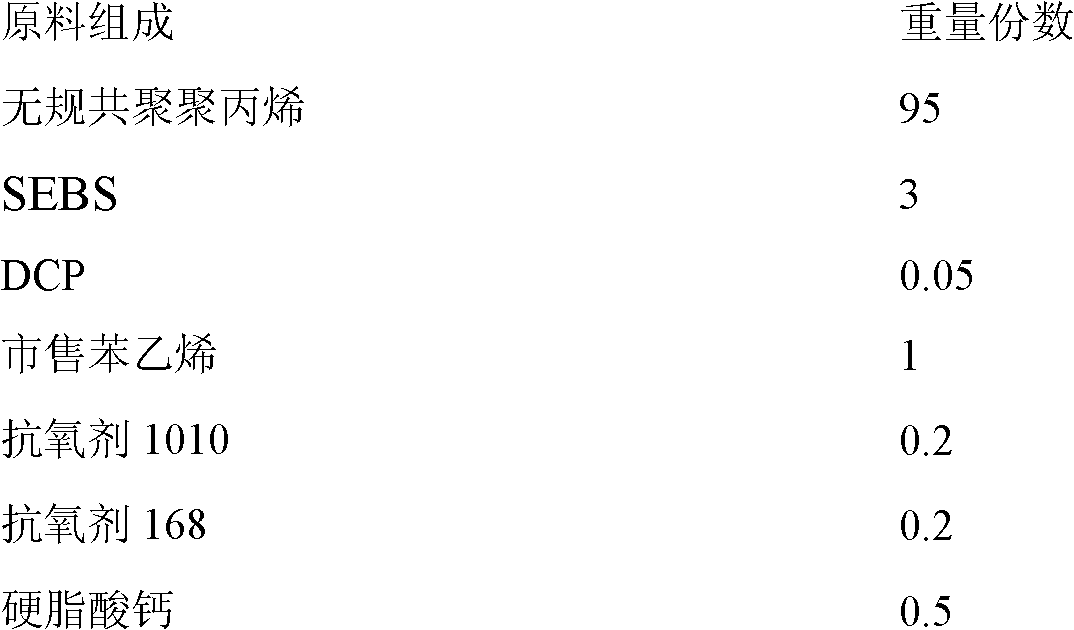

Embodiment 1

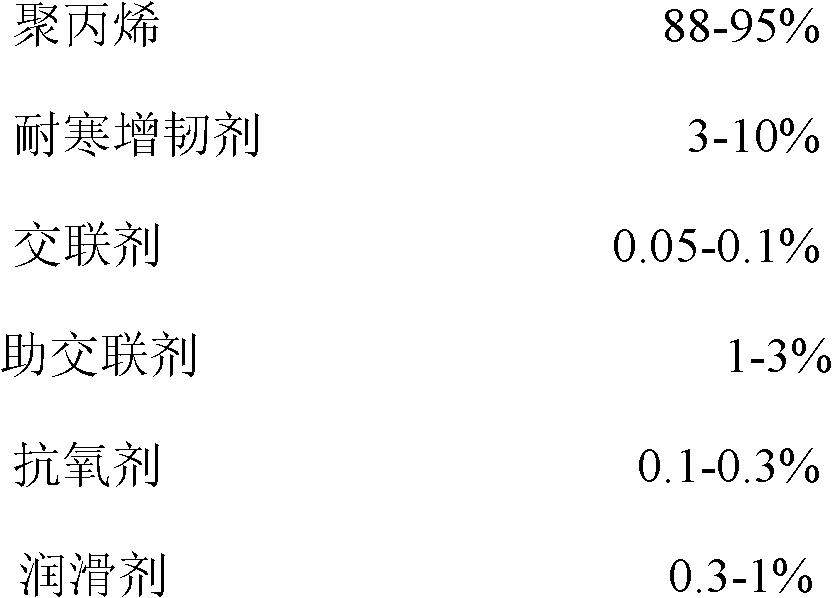

[0016] A transparent, cold-resistant and high-melt-strength polypropylene material for an automobile expansion tank, mainly composed of the following raw materials:

[0017]

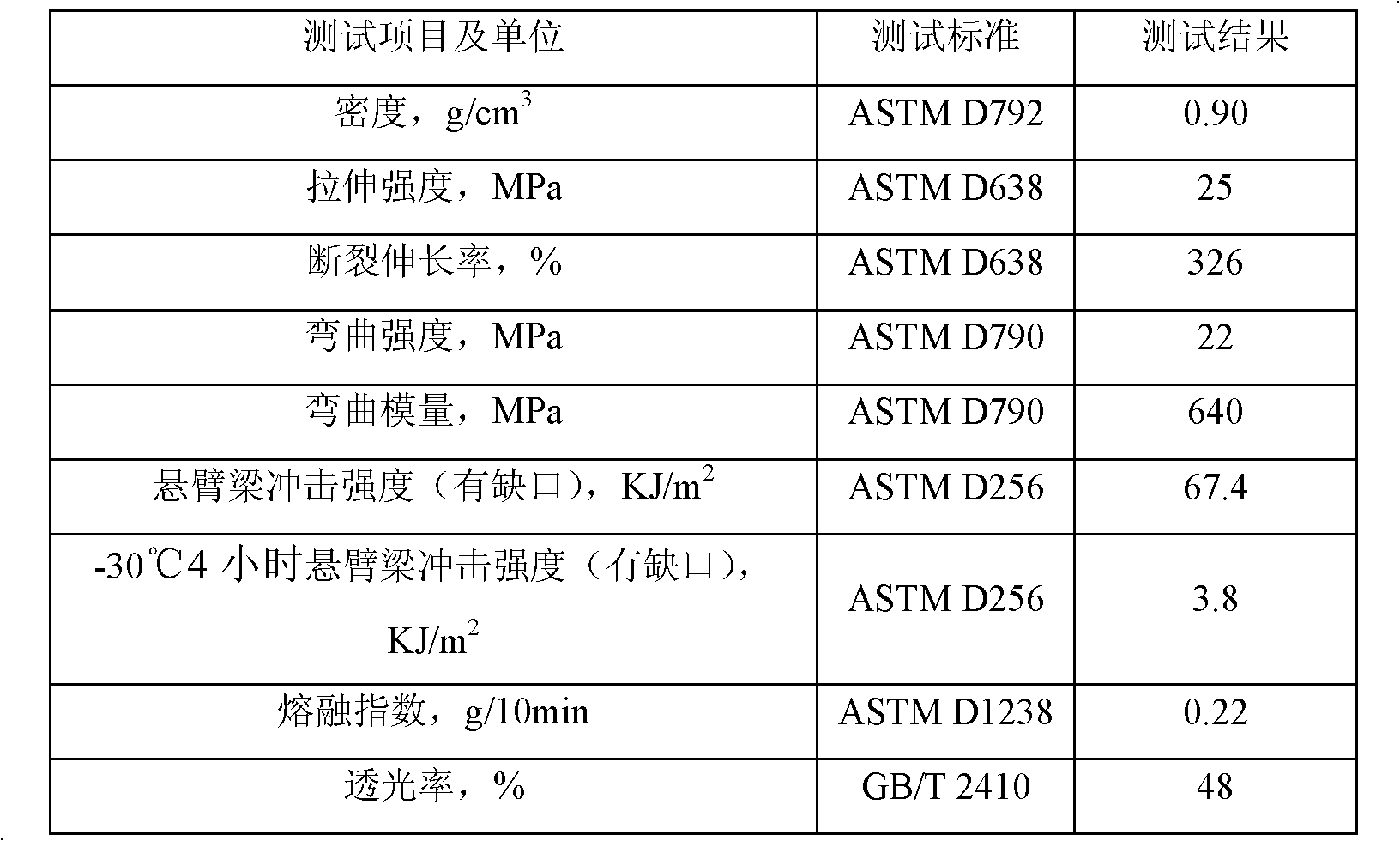

[0018] Weigh polypropylene, cold-resistant and toughening agent, cross-linking agent, styrene, antioxidant and lubricant in a high-speed mixer and mix them uniformly in a high-speed mixer, and then melt, blend, react, extrude and granulate in a twin-screw extruder. The process conditions of the extruder are: the temperature of the 1-2 zone of the twin-screw extruder is 160-190°C, the temperature of the 3-4 zone is 210-230°C, the temperature of the 5-6 zone is 220-240°C, and the temperature of the 7-8 zone The temperature is 220-230°C, the head temperature is 210-220°C, and the screw speed is 300-350 rpm. The obtained extruded pellets were dried and then injection-molded into standard specimens to test their properties. The results are shown in Table 1.

[0019] Table 1 embodiment 1 gained material pe...

Embodiment 2

[0022] A transparent, cold-resistant and high-melt-strength polypropylene material for an automobile expansion tank, mainly composed of the following raw materials:

[0023]

[0024] The preparation steps are the same as in Example 1.

[0025] The obtained extruded pellets were dried and injection-molded into standard specimens, and their properties were tested. The results are shown in Table 2.

[0026] Table 2 embodiment 2 gained material properties test result

[0027]

[0028]

Embodiment 3

[0030] A transparent, cold-resistant and high-melt-strength polypropylene material for an automobile expansion tank, mainly composed of the following raw materials:

[0031]

[0032] The preparation steps are the same as in Example 1.

[0033] The obtained extruded pellets were dried and injection-molded into standard specimens, and their properties were tested. The results are shown in Table 3.

[0034] Table 3 embodiment 3 gained material properties test result

[0035]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com