Cold-rolled steel strip for flux-cored welding wire with low-temperature toughness and production method thereof

A technology of cold-rolled strip steel and flux-cored welding wire, which is applied in the direction of metal rolling, etc., can solve the problems of poor low-temperature toughness, poor formability, and unreasonable composition control of strip steel, so as to eliminate the yield plateau and prevent Lüdes stripping. , Improve the effect of anti-aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

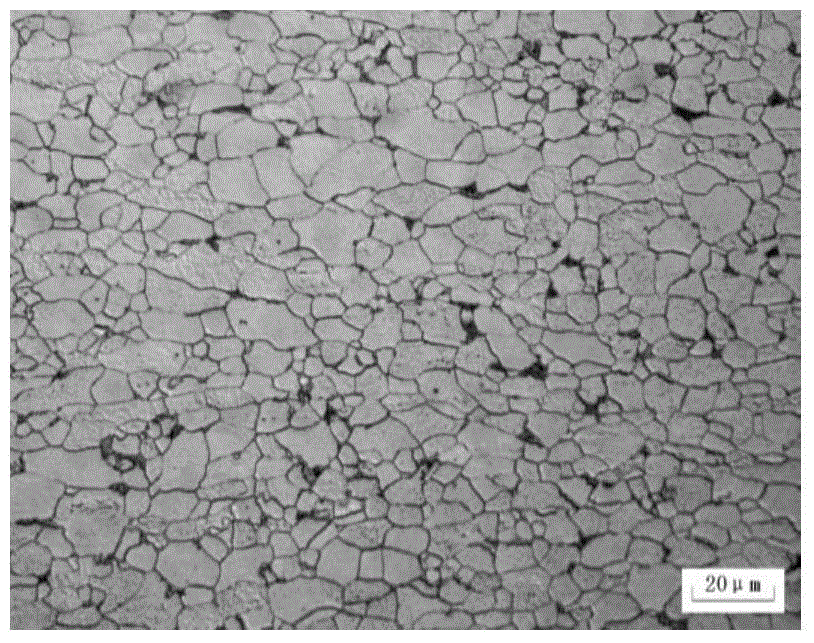

Image

Examples

Embodiment Construction

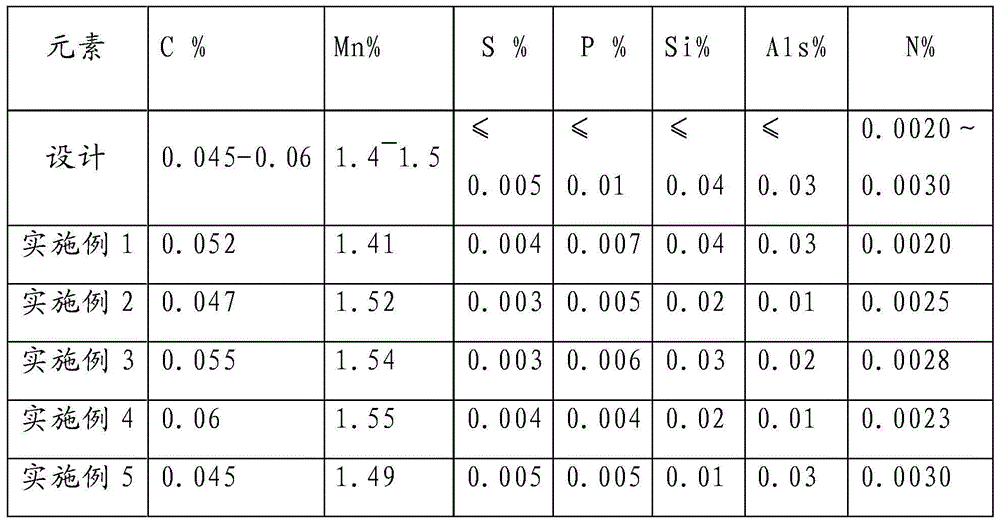

[0016] A cold-rolled steel strip for flux-cored welding wire with low-temperature toughness provided by the embodiment of the present invention, its chemical composition and mass percentage are: C, 0.045-0.06%; Mn, 1.4-1.5%; Si, ≤0.04%; P, ≤0.01%; S, ≤0.005%; Als, ≤0.03%, N, 0.0020~0.0030%, the balance is Fe and unavoidable impurities.

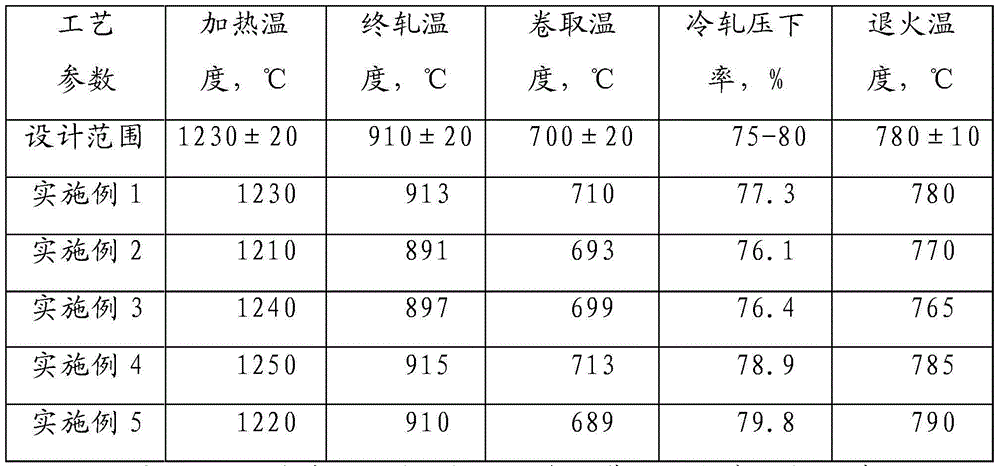

[0017] A kind of production method that the present invention provides has the cold-rolled steel strip for flux-cored welding wire of low-temperature toughness, comprises the following steps:

[0018] 1) The chemical composition and mass percentage are: C, 0.045-0.06%; Mn, 1.4-1.5%; Si, ≤0.04%; P, ≤0.01%; S, ≤0.005%; Als, ≤0.03%, N, 0.0020~0.0030%, the balance is Fe and unavoidable impurities, desulfurization, converter blowing, RH vacuum refining, continuous casting to obtain continuous casting slabs;

[0019] 2) Heating the continuous casting slab to 1230±20°C for hot rolling, controlling the temperature at 910±20°C during final rolling, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact absorption energy | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com