Rigid PE-RT (polyethylene of raised temperature resistance) pipe and production process thereof

A PE-RT and production process technology, applied in the field of hard PE-RT pipe and its production process, to achieve the effect of improving production efficiency, prolonging service life and good ring stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

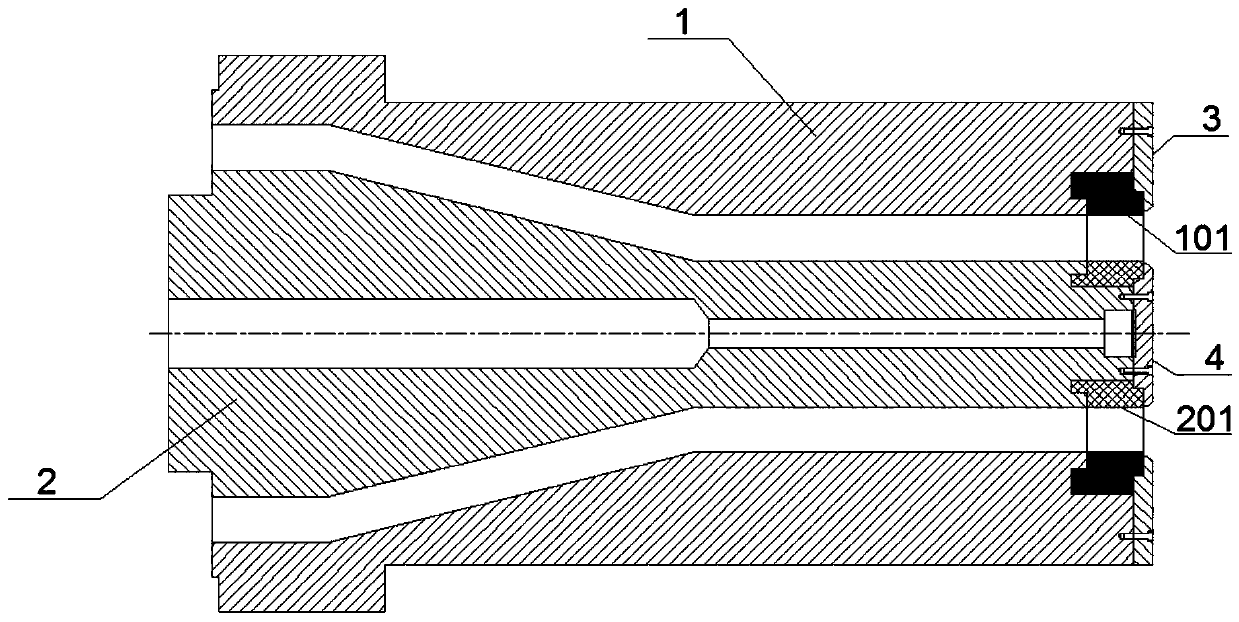

Image

Examples

Embodiment 1

[0028] Embodiment 1, carry out the production of the PE-RT pipe material of diameter 30-50mm, described pipe material comprises 100 parts of PE-RT resins, 1.6 parts of tribasic lead sulfate, 1 part of tribasic sulfuric acid Lead phosphate, 0.3 parts lead stearate, 0.2 parts calcium stearate, 0.3 parts barium stearate, 0.4 parts stearic acid, 0.35 parts paraffin wax, 0.15 parts PE wax, 15 parts light calcium carbonate and 0.011 parts carbon black , the production process of the rigid PE-RT pipe according to the above-mentioned proportioning comprises the following steps:

[0029] A. Raw material mixing

[0030] PE-RT resin, tribasic lead sulfate, tribasic lead phosphite, lead stearate, calcium stearate, barium stearate, stearic acid, paraffin wax, PE wax, light calcium carbonate and carbon black Add it into the drying mixer according to the proportion, remove the water, dry it fully, and mix it to get the mixture. The drying temperature is set at 75°C;

[0031] B. Mixing

[...

Embodiment 2

[0043] Example 2, as another embodiment of the proportioning of the pipes in Example 1, the pipes include 100 parts of PE-RT resin, 1 part of tribasic lead sulfate, 0.8 parts of tribasic lead sulfate according to the ratio of parts by mass. Lead phosphite, 0.25 parts lead stearate, 0.2 parts calcium stearate, 0.3 parts barium stearate, 0.55 parts stearic acid, 0.45 parts paraffin, 0.18 parts PE wax, 28 parts light calcium carbonate and 0.012 parts carbon black.

Embodiment 3

[0044] Example 3, as another embodiment of the proportioning of the pipes in Example 1, the pipes include 100 parts of PE-RT resin, 2.3 parts of tribasic lead sulfate, 1.3 parts of tribasic lead sulfate according to the ratio of parts by mass. Lead phosphite, 0.38 parts of lead stearate, 0.2 parts of calcium stearate, 0.3 parts of barium stearate, 0.25 parts of stearic acid, 0.25 parts of paraffin, 0.12 parts of PE wax, 4 parts of light calcium carbonate and 0.01 part of carbon black.

[0045] The pipe material ratio and processing technology adopted in the present invention have improved low-temperature brittleness resistance. The low-temperature brittleness resistance is -78°C, which is 8°C higher than the existing -70°C. Generally, there will be no low-temperature brittleness problem in the environment; there is also a relatively obvious increase in high-temperature resistance, and the long-term high-temperature resistance is 94 ° C, which is 4 ° C higher than the conventio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com