A kind of anti-high-power microwave shielding film and preparation method thereof

A high-power microwave and shielding film technology, applied in the direction of magnetic/electric field shielding, electrical components, etc., can solve the problems of not being able to shield electromagnetic effects and ultraviolet rays, the effect of shielding electromagnetic interference is not good enough, and the production process of shielding film is not perfect, etc., to achieve Enhanced electromagnetic shielding effect, excellent microwave absorption performance, and improved surface activity

Active Publication Date: 2022-06-03

广东国科电磁科技有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] In addition, in addition to electromagnetic interference, ultraviolet rays are ubiquitous in the environment. At the same time, they will cause damage to the human body and affect material devices. However, most of the electronic device casings on the market are made of plastic, but as we all know, plastic is only an insulating material. It cannot shield electromagnetic effects and ultraviolet rays. Therefore, shielding films are produced on the market to solve these problems. However, the existing production process of shielding films on the market is not perfect enough, and the effect of shielding electromagnetic interference is not good enough.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

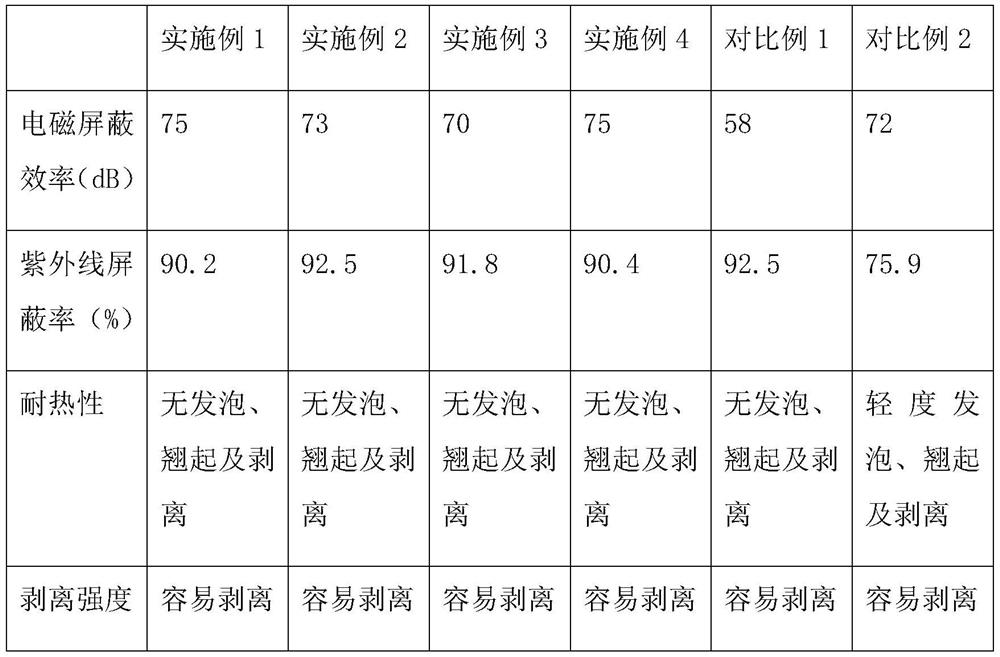

Effect test

Embodiment 1

[0054] S5: soak the polyimide fiber in a 5% sodium hydroxide solution at 60° C., react for 20 min, wash with water,

[0058] S8: the slurry is extruded, solidified, and dried to form a shielding film.

Embodiment 2

[0070] S8: the slurry is extruded, solidified, and dried to form a shielding film.

Embodiment 3

[0082] S8: the slurry is extruded, solidified, and dried to form a shielding film.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a high-power microwave-resistant shielding film and a preparation method thereof, comprising the following steps: S1: coating the surface of a modified carbon nanotube with a metal layer, that is, a coated carbon nanotube; S2: combining zinc ferrite and wood Mixing plain-titanium dioxide is modified zinc ferrite; S3: preparing polypropylene elastomer; S4: mixing polyimide fiber, aramid pulp, and carbon fiber evenly, and performing in-situ polymerization and activation reactions, which is Electromagnetic shielding material; S5: Prepare adhesive; S6: Dissolve epoxy resin in acetone solution, add coated carbon nanotubes, graphite, modified zinc ferrite, polypropylene elastomer, electromagnetic shielding material, and adhesive and mix evenly. It is the slurry; S7: The slurry is extruded, solidified, and dried to form the shielding film. The shielding film prepared by this preparation method has good electromagnetic shielding effect, heat resistance, wave absorption, tensile strength, and stability. properties, insulation and UV shielding.

Description

A kind of shielding film against high-power microwave and preparation method thereof technical field [0001] The present invention relates to the technical field of shielding films, in particular to a shielding film resistant to high-power microwaves and a preparation method thereof. Background technique [0002] With the development of science and technology, the 5G era has come, and the frequency of use of electronic products is getting higher and higher. Mobile phones have become a part of our lives, but these electronic devices are unavoidable to generate electromagnetic interference, which makes the Electromagnetic interference is ubiquitous in our daily environment. In addition to affecting the normal operation of electronic devices, electromagnetic interference also It will cause harm to the human body. In some European and American countries, strict regulations have been made on electromagnetic interference. In addition, in addition to electromagnetic interferen...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08L63/00C08L53/00C08L23/08C08L79/08C08L77/10C08L33/08C08K9/02C08K9/04C08K3/04C08K3/24C08K9/10C08K3/22C08K7/06C08J5/18H05K9/00

CPCC08J5/18H05K9/0081C08J2363/00C08J2453/00C08J2423/08C08J2479/08C08J2477/10C08J2433/08C08K9/02C08K9/04C08K3/041C08K2201/011C08K3/24C08K9/10C08K2003/2241C08K2003/222C08K7/06

Inventor 代忠信戴宗良王为皓邓海扑刘锋马鑫海王丽萍

Owner 广东国科电磁科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com