Rotary bioreactor

A bioreactor, rotary technology, used in bioreactor/fermenter combinations, specific-purpose bioreactors/fermenters, biochemical instruments, etc., can solve the problems of non-uniformity, high cost, cross-contamination, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

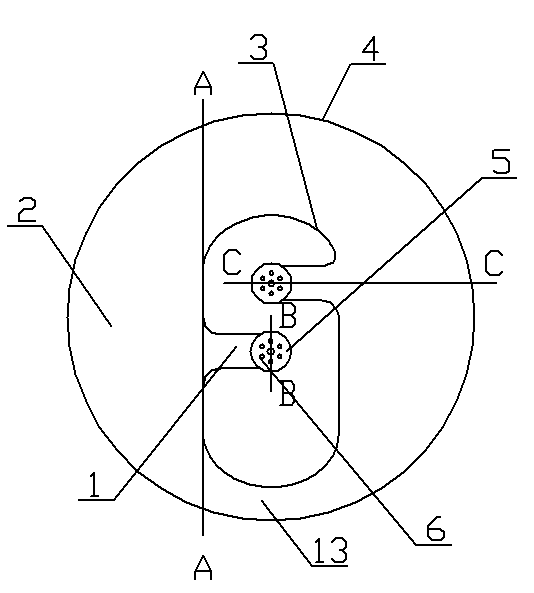

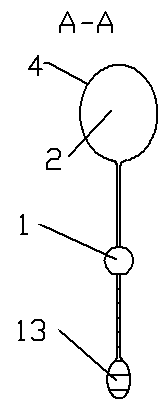

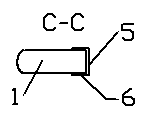

[0060] A kind of embodiment 1 of rotary bioreactor, in Figure 1~4 Among them, the bioreactor includes a loop cavity, and the inner cavity wall of the loop cavity is a smooth cavity wall without sharp edges and corners. The outer edge 4 of the loop cavity is circular, and the inner edge 3 of the loop cavity is waist-shaped. The waist shape here is formed by the convex arcs provided at both ends and connecting the two arcs. A shape formed by two straight lines. The center point of the inner edge 3 is not at the center of the outer edge 4. In this way, a narrow section 13 appears on the loop cavity, and adjacent to the narrow section 13 is an open section 2. The length of the narrow section 13 is much smaller than that of the open section. The length of segment 2. An inlet and outlet pipe 1 is provided on the inner side wall of the open section 2, and the inlet and outlet pipe 1 is used for feeding in and out of culture materials such as culture fluid, cultured cells and gas. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com