Production method of kraft cardboard with ultra low gram weight

A production method and technology of heavy kraft cardboard, applied in the production field of ultra-low grammage kraft cardboard, can solve the problems of heavy grammage, poor strength, and large process investment, etc., achieve high vehicle speed, reduce production costs, and improve economic efficiency. benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

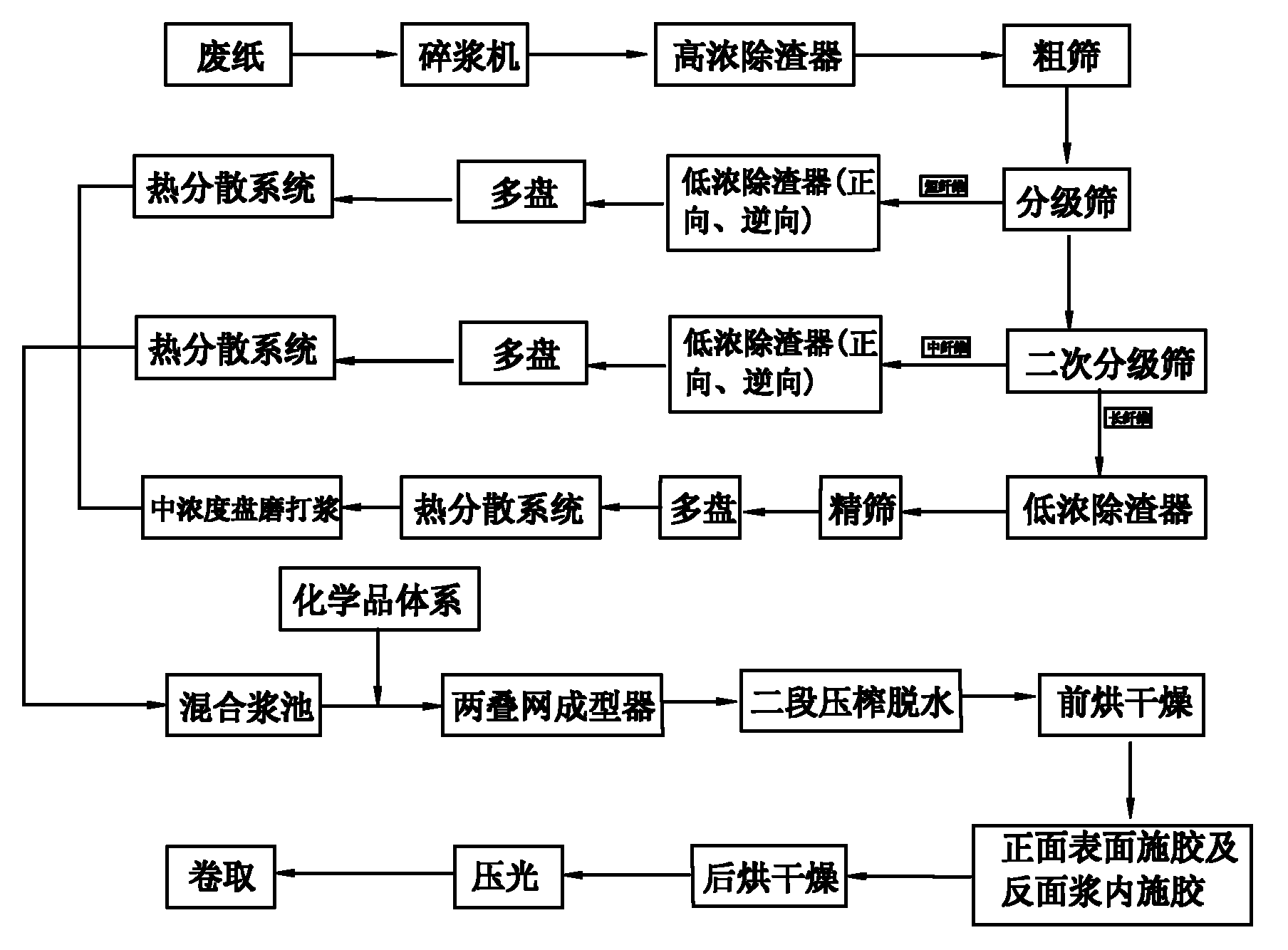

[0042] Such as figure 1 As shown, the ultra-low grammage kraft cardboard production method of the present embodiment comprises the following process steps:

[0043] 1) Ingredients; the ingredients mentioned are imported waste paper: domestic waste paper in the weight percentage of 40%: 60%. Imported waste paper includes American waste and European waste. American waste (AOCC) is one or both of 11#AOCC and 12#AOCC; European waste (EOOC) is one or both of A5 EOOC and A4 EOOC; Domestic waste paper (COCC) refers to used packaging cartons and cardboard recycled in the domestic market; imported waste paper with a weight percentage of 40% is one or a mixture of American waste or European waste. The ingredients in the present invention do not add any UKP wood pulp; the UKP wood pulp is kraft wood pulp refined from primary wood pulp, which mainly improves the indicators such as paper breakage resistance and ring pressure, and is expensive.

[0044] 2) Add water and disintegrate to m...

Embodiment 2

[0060] Such as figure 1 As shown, the ultra-low grammage kraft cardboard production method of the present embodiment comprises the following process steps:

[0061] 1) Ingredients; the ingredients mentioned are imported waste paper: domestic waste paper in a weight percentage of 50%: 50%. Imported waste paper includes American waste and European waste. American waste (AOCC) is one or both of 11#AOCC and 12#AOCC; European waste (EOOC) is one or both of A5 EOOC and A4 EOOC; Domestic waste paper (COCC) refers to used packaging cartons and cardboard recycled in the domestic market; imported waste paper with a weight percentage of 50% is one or a mixture of American waste or European waste. The ingredients in the present invention do not add any UKP wood pulp; the UKP wood pulp is kraft wood pulp refined from primary wood pulp, which mainly improves the indicators such as paper breakage resistance and ring pressure, and is expensive.

[0062] 2) Add water and disintegrate to mak...

Embodiment 3

[0078] Such as figure 1 As shown, the ultra-low grammage kraft cardboard production method of the present embodiment comprises the following process steps:

[0079] 1) Ingredients; the ingredients mentioned are imported waste paper: domestic waste paper in a weight percentage of 60%: 40%. Imported waste paper includes American waste and European waste. American waste (AOCC) is one or both of 11#AOCC and 12#AOCC; European waste (EOOC) is one or both of A5 EOOC and A4 EOOC; Domestic waste paper (COCC) refers to used packaging cartons and cardboard recycled in the domestic market; imported waste paper with a weight percentage of 60% is one or a mixture of American waste or European waste. The ingredients in the present invention do not add any UKP wood pulp; the UKP wood pulp is kraft wood pulp refined from primary wood pulp, which mainly improves the indicators such as paper breakage resistance and ring pressure, and is expensive.

[0080] 2) Add water and disintegrate to mak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tightness | aaaaa | aaaaa |

| Ring pressure index | aaaaa | aaaaa |

| Bursting strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com