Rock bolt system based on fiber reinforced plastic bolt and ultrahigh-performance cement-based bonding and anchoring medium

A fiber-reinforced plastic, ultra-high-performance technology, applied in infrastructure engineering, construction, sheet pile walls, etc., can solve the problems affecting structural safety and durability, large amount of materials and underground engineering, prone to corrosion and aging, etc. problem, to achieve the effect of light weight, good durability, and weight-free rust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

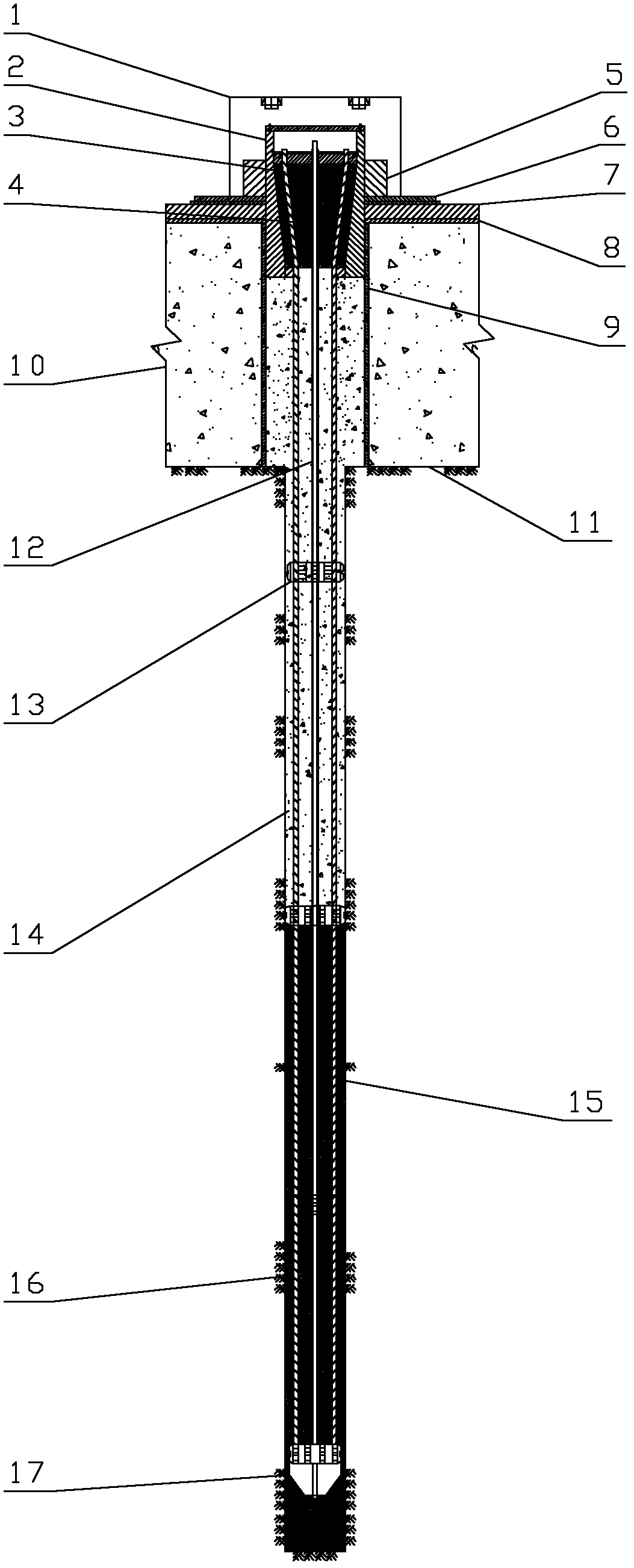

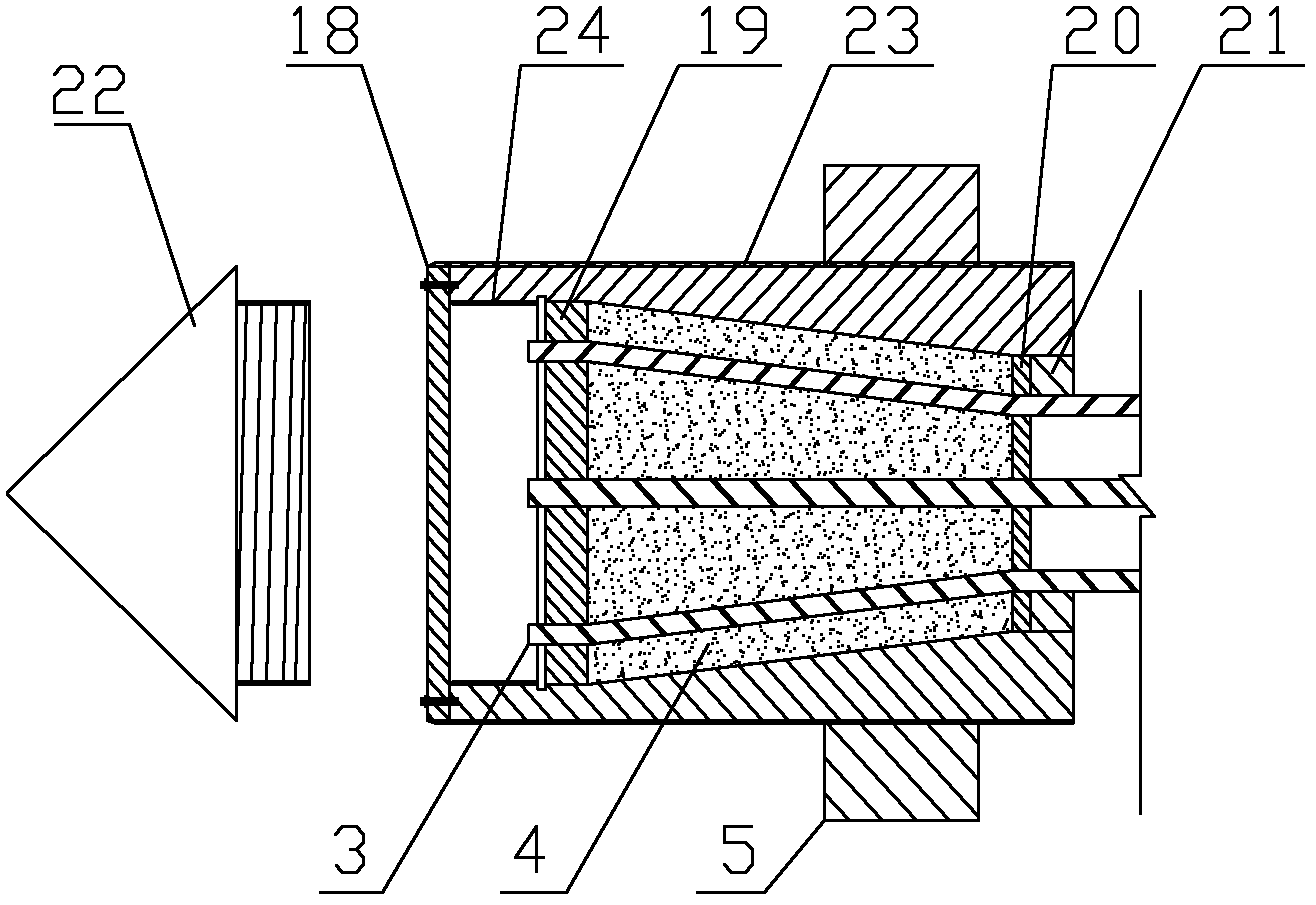

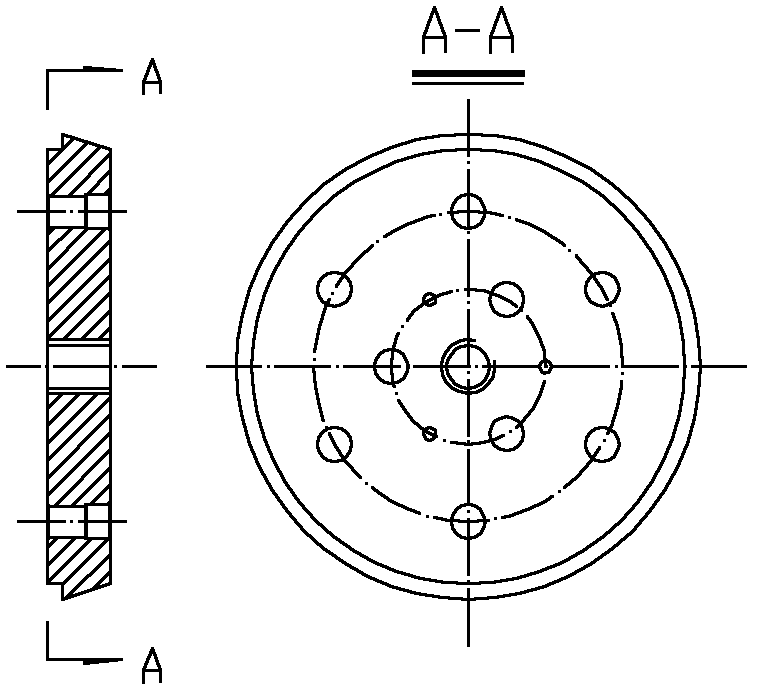

[0033] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the implementation manners of the present invention are not limited thereto.

[0034] According to the present invention, a rock anchor system based on fiber-reinforced plastic bar anchor and ultra-high-performance cement-based bonded anchoring medium, the specific implementation steps are as follows:

[0035] (1) Determine the anchor material and anchoring bonding medium: determine the specific type of fiber-reinforced composite plastic bars, use it as the anchor material, determine the raw materials and ratio of ultra-high performance cement-based composite materials, and use it as the anchoring bond medium;

[0036] (2) Design the anchoring system: After the material is determined, the material properties are studied, and the multi-fiber reinforced plastic tendon anchor rod 3 and the ultra-high performance cement-ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Taper | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com