Multi-disk wet-type brake for loading machine

A technology of wet brakes and loaders, applied in hydraulic brakes and other directions, can solve problems such as poor heat dissipation conditions, unstable work, and potential safety hazards, and achieve the effects of good sealing and heat dissipation, simple structure, and convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

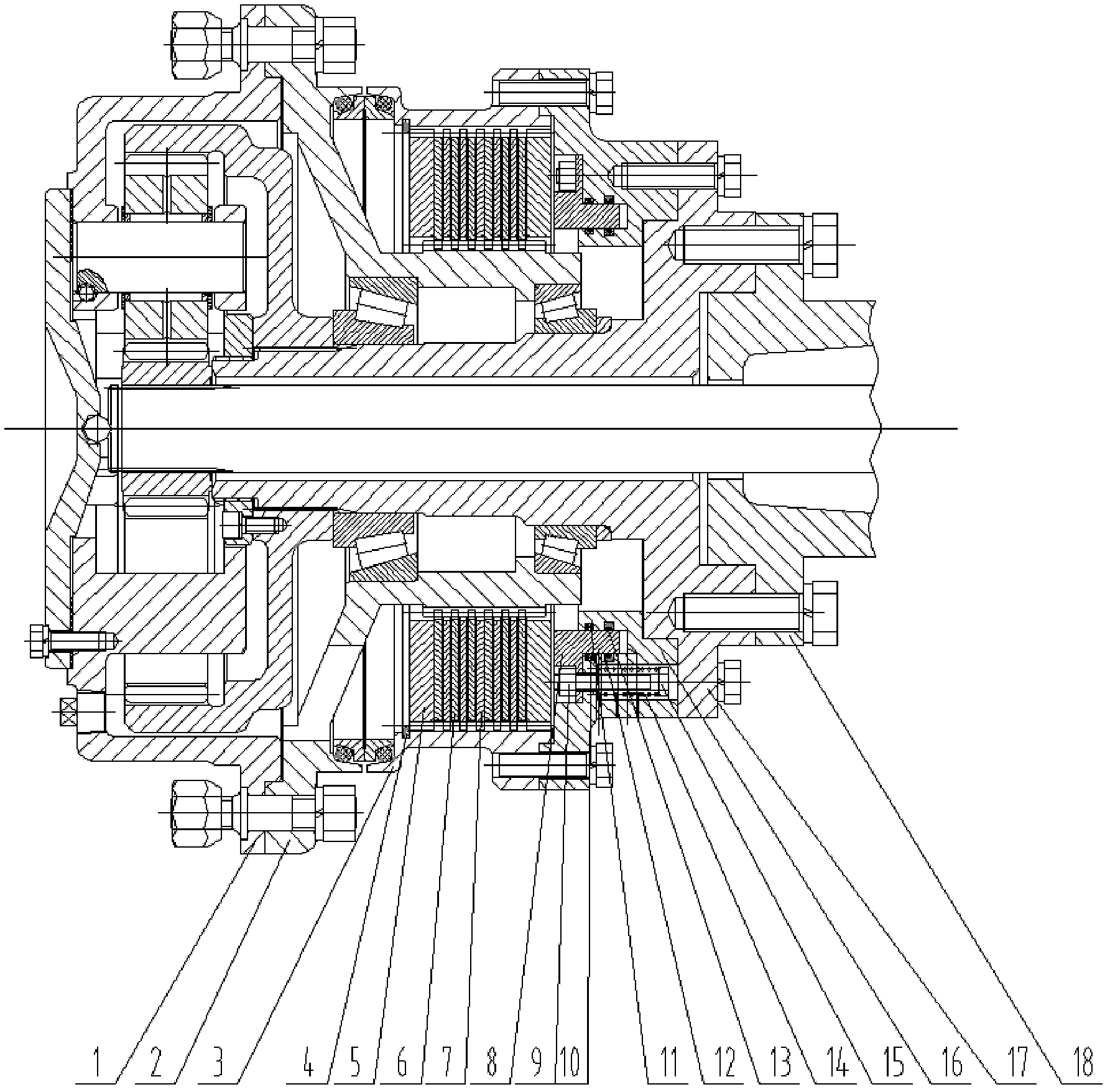

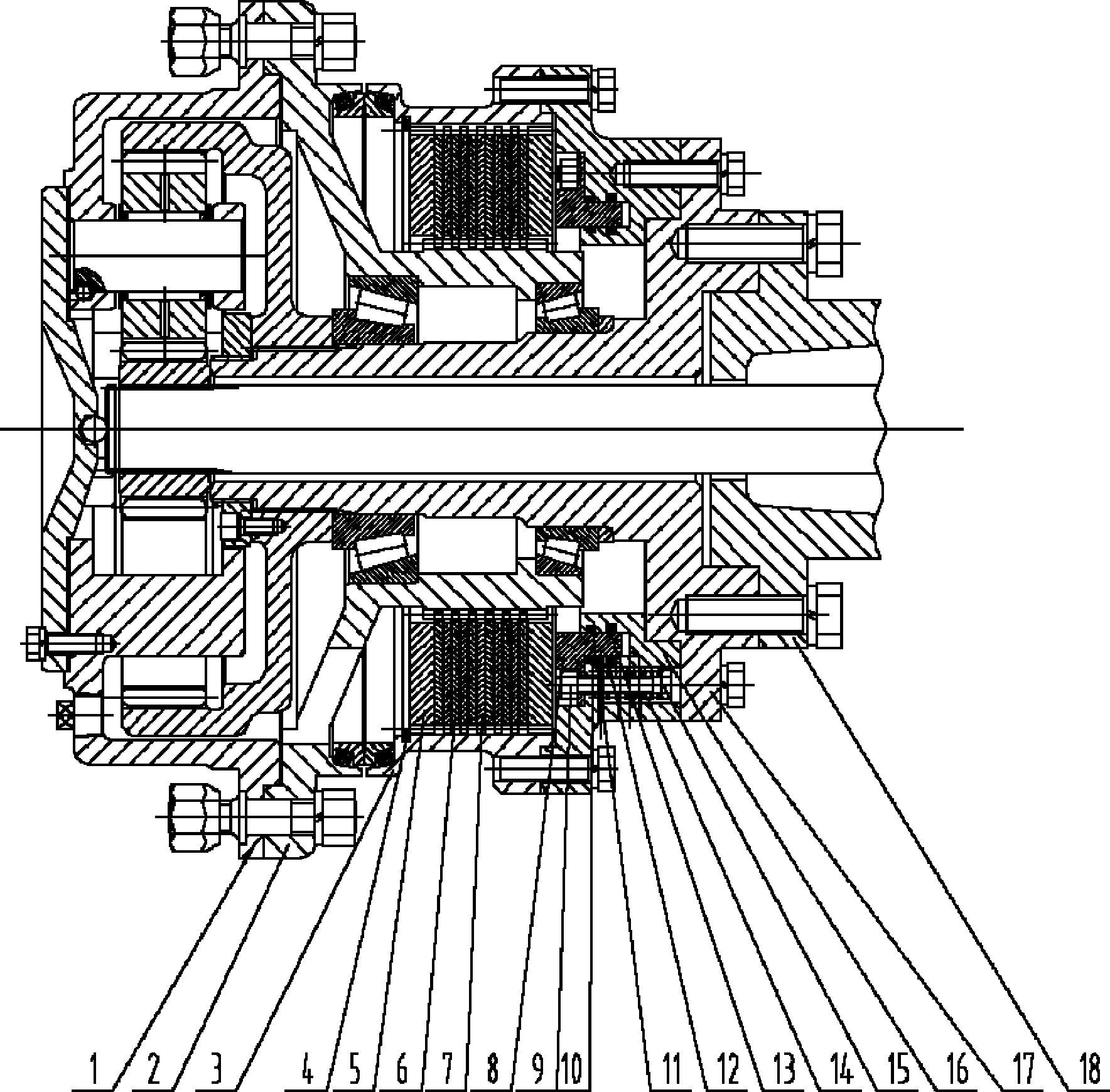

[0025] A multi-disc wet brake for a loader, the wheel housing 2 is installed on the planetary wheel frame 1, and the brake housing 3 has a retaining ring 4, a left pressure bearing plate 5, a right pressure bearing plate, a friction plate 6 and a brake plate 7, The retaining ring 4 restricts the left pressure bearing plate 5, the friction discs 6 and brake discs 7 arranged at intervals, and the right pressure bearing plate in the brake housing 3, and the brake housing 3, the oil cylinder 16 and the support shaft 17 are connected into one body by bolts , the support shaft 17 is fixed to the axle housing 18, the friction discs 6 arranged at intervals are splined with the wheel housing 2 and can move axially, the brake discs 7 arranged at intervals, the left pressure plate 5, the right pressure plate and the brake The housing 3 has a spline connection and can move axially, and the piston 8 of the oil cylinder 16 can move axially to push the pressure bearing plate, and the piston 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com