Controller area network (CAN)-control-based auxiliary control unit for locomotive

An auxiliary control unit and network control technology, applied in the direction of total factory control, total factory control, electrical program control, etc., can solve problems such as real-time performance and poor reliability, and achieve the effect of meeting work requirements and overcoming real-time performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

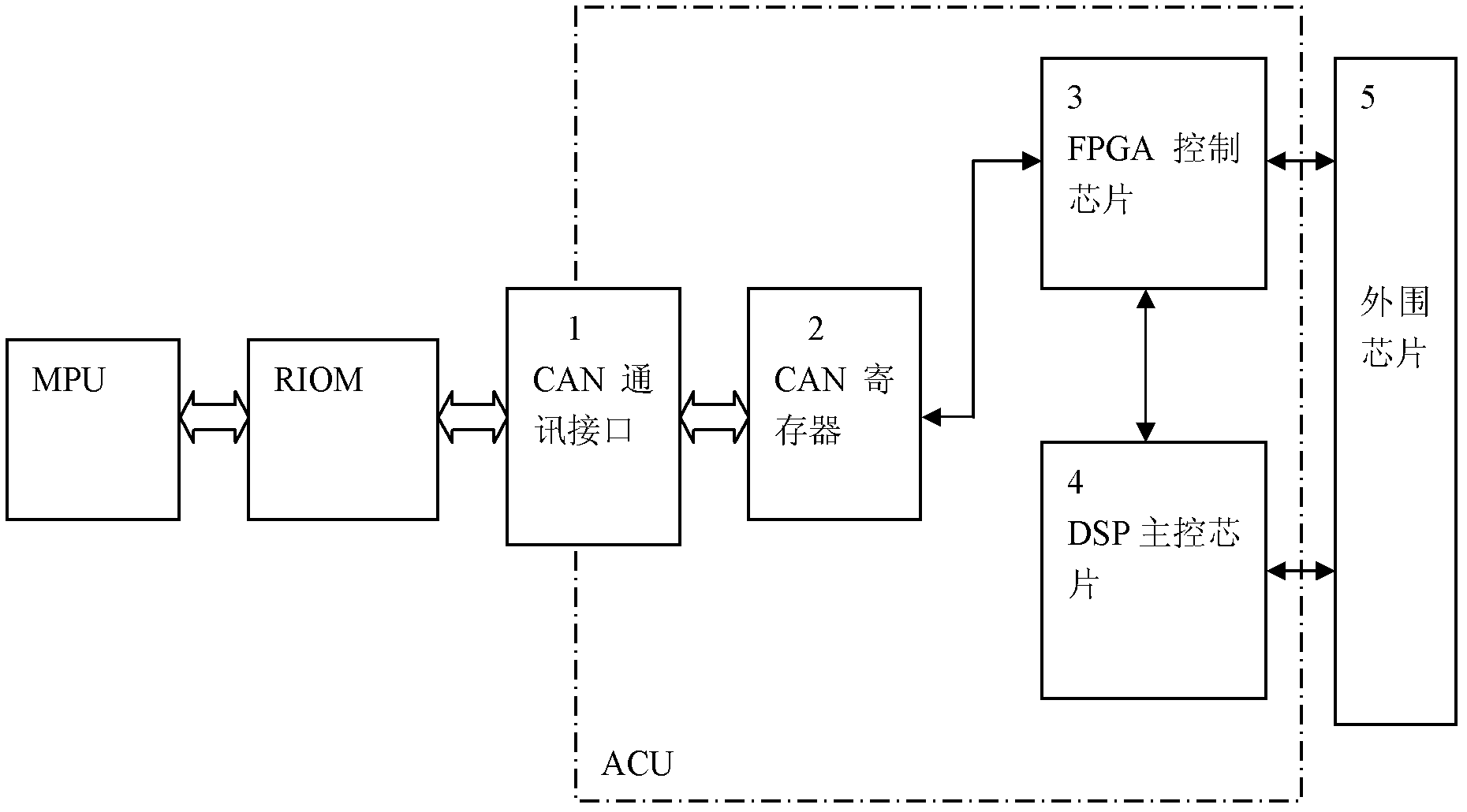

[0013] Such as figure 1 As shown, the locomotive auxiliary control unit based on CAN network control includes CAN communication interface 1, CAN register 2, FPGA control chip 3 and DSP main control chip 4; CAN communication interface 1 and CAN register 2 are mainly for processing input and output The network data input by the module (RIOM) is converted and stored; the FPGA control chip 3 is used for simple processing of the data in the CAN register 2, and the program converts the CAN communication data into the data that can be recognized by the DSP main control chip 4 form, control the logic circuit, and send the data to the DSP main control chip 4 for control processing; the DSP main control chip 4 realizes the logic of controlling the start, stop, emergency mode, and action of the contactor through the CAN bus of the entire auxiliary control unit, and at the same time Send the collected analog and digital values to the main control unit (MPU), feed back the actual contact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com