Preparation method for ultraviolet-proof thin-film solar cell

A solar cell and anti-ultraviolet technology, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems that cannot be directly applied, and cannot effectively prevent the adverse effects of ultraviolet rays on thin-film solar cells, and achieve expanded utilization, low cost, and simple process easy to control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

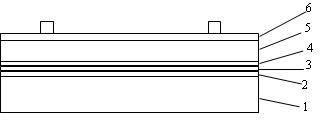

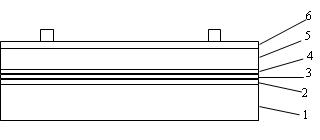

[0022] A kind of preparation method of anti-ultraviolet thin-film solar cell, selects glass as substrate material, at first on glass substrate 1 material by plasma-enhanced chemical vapor deposition (PECVD) (microwave power 600W, H 2 Flow 20sccm, SiH 4 The flow rate is 8 sccm, the substrate temperature is 200°C, and the deposition time is 2 minutes) to prepare a 12nm thick amorphous silicon film; then turn off the SiH 4 Gas source, maintain H plasma discharge, use H plasma to etch the amorphous silicon film in situ for 1 minute, and prepare a layer of nano-silicon film layer 2 with a diameter of 2 nm and a thickness of 8 nm; Si prepared by microwave plasma technology 3 N 4 Anti-reflection layer 3 (microwave power 550-600W, N2 flow rate 25-35sccm, SiH4 flow rate 8-10sccm, substrate temperature 200-300°C, deposition time 30 minutes-2 hours); finally follow the conventional thin film battery preparation process before Electrode 4, p-i-n single-junction or multi-junction batter...

Embodiment 2

[0024] A preparation method of an ultraviolet-resistant thin-film solar cell, select glass as the substrate material, first pass plasma enhanced chemical vapor deposition (PECVD) on the glass substrate 1 material (parameters are the same as in Example 1, and deposit for 90 seconds) Prepare a 10nm thick amorphous silicon film; then turn off the SiH 4 gas supply, then close the SiH 4 Gas source, maintain H plasma discharge, use H plasma to etch the amorphous silicon film in situ for 3 minutes, and prepare a nano-silicon film layer 2 with a diameter of 5 nm and a thickness of 5 nm; Prepared on Si 3 N 4 Anti-reflection layer 3; finally prepare the front electrode 4, p-i-n single-junction or multi-junction battery 5 and back electrode 6 sequentially according to the conventional thin-film battery preparation process, and the ultraviolet-proof thin-film solar cell can be obtained after conventional battery packaging. After testing, this Thin film solar cells (such as figure 1 ) ...

Embodiment 3

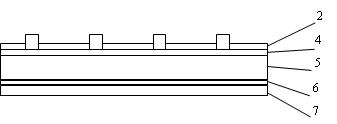

[0026] A method for preparing an ultraviolet-resistant thin-film solar cell. Stainless steel is selected as an opaque substrate 7. First, a back electrode 6, an n-i-p single-junction or multi-junction cell 5 and a front electrode 4 are sequentially prepared on the stainless steel material according to a conventional thin-film cell manufacturing process; Then prepare a 10nm thick amorphous silicon film by plasma enhanced chemical vapor deposition (PECVD) (parameters are the same as in Example 1, deposited for 90 seconds); then close the SiH 4 Gas source, maintain H plasma discharge, use H plasma to etch the amorphous silicon film in situ for 1 minute, and prepare a nano-silicon film layer 2 with a diameter of 2 nm and a thickness of 6 nm; finally, after conventional battery packaging UV-resistant thin-film solar cells (such as figure 2 ), after testing, the conversion efficiency of this thin-film solar cell in the ultraviolet band has increased by 61%, and the service life has...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com