Wireless sensor network (WSN)-based staff tracking and monitoring system for petrochemical sulfur-containing device

A monitoring system and employee technology, applied in transmission systems, signal transmission systems, instruments, etc., can solve the problems of untimely data, high price, and danger of measuring personnel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

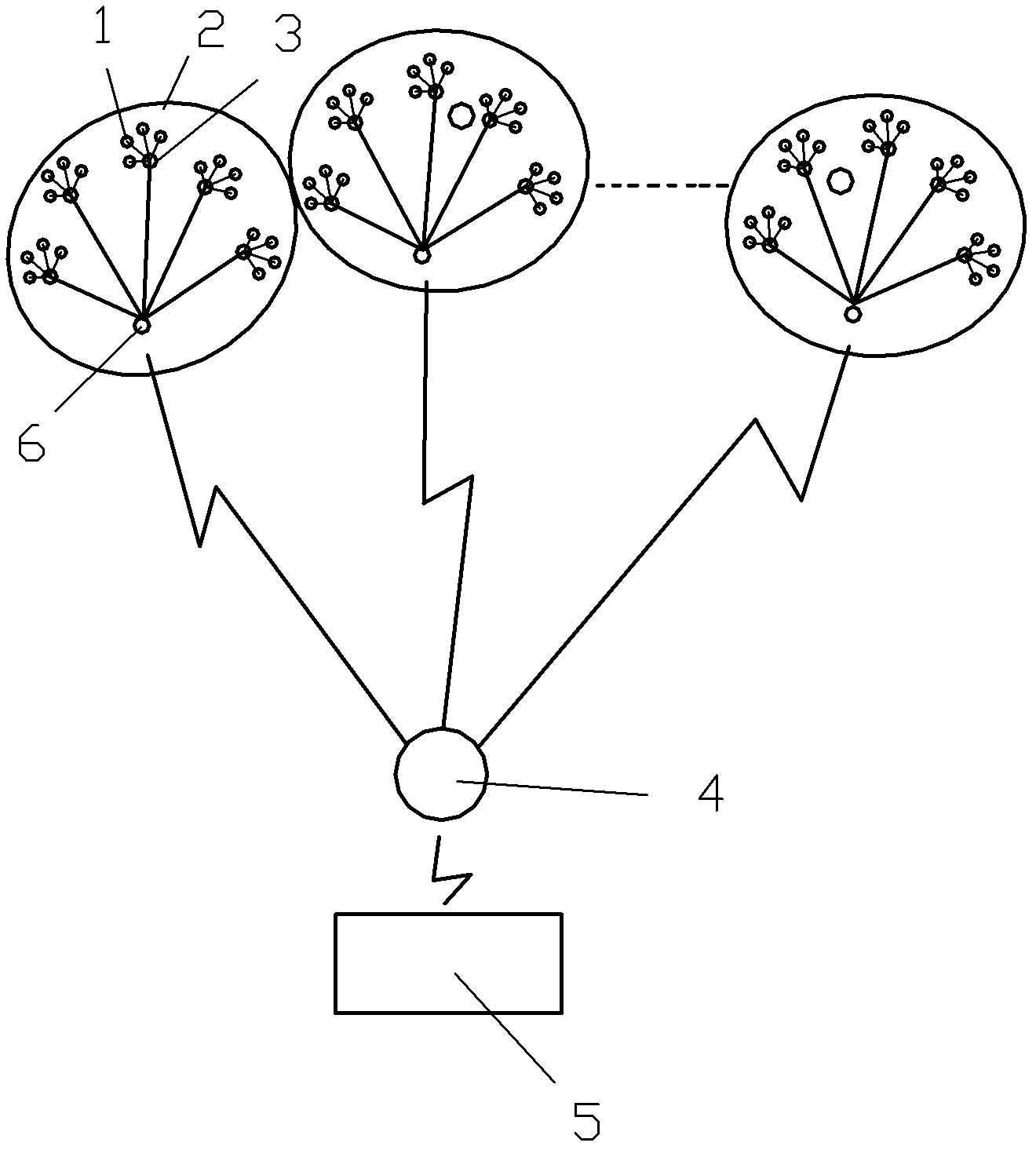

[0016] refer to figure 1 and figure 2 , the WSN-based petrochemical sulfur-containing plant employee tracking and monitoring system provided by the present invention, the sulfur-containing plant monitoring area is divided into a plurality of monitoring cells 2, each monitoring cell 2 deploys a plurality of sensor nodes 1 and installs a convergence of these sensor nodes Node 6, the convergence node 6 is connected with the in-plant computer network 5 through the gateway node 4; 2 A portable hydrogen sulfide detector that collects the S concentration and locates and transmits information through the wireless communication module of the sensor node 1.

[0017] In the above, among 3 to 5 adjacent or similar sensor nodes 1 in each monitoring cell, there is a leader node 3 for collecting monitoring data.

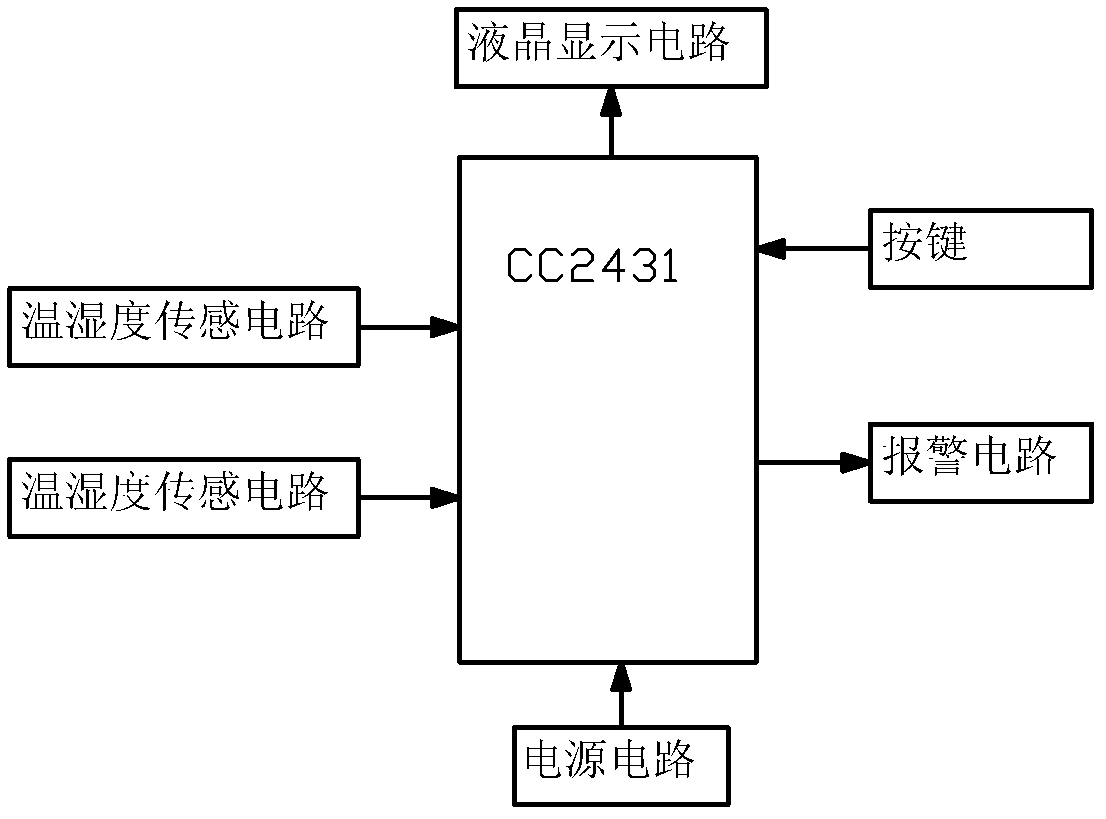

[0018] The portable hydrogen sulfide detector is composed of CC2431 main control circuit, power supply circuit, temperature and humidity sensing circuit, hydrogen sulfide detect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com