Deformed polymer tube and completely biodegradable polymer stent prepared by same

A polymer tube and deformation technology, which is applied in the field of preparation of medical implant stents, can solve the problems of uniform wall thickness and shape stability of difficult tubes, and achieve delayed physical aging time, good radial strength, and simple preparation methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

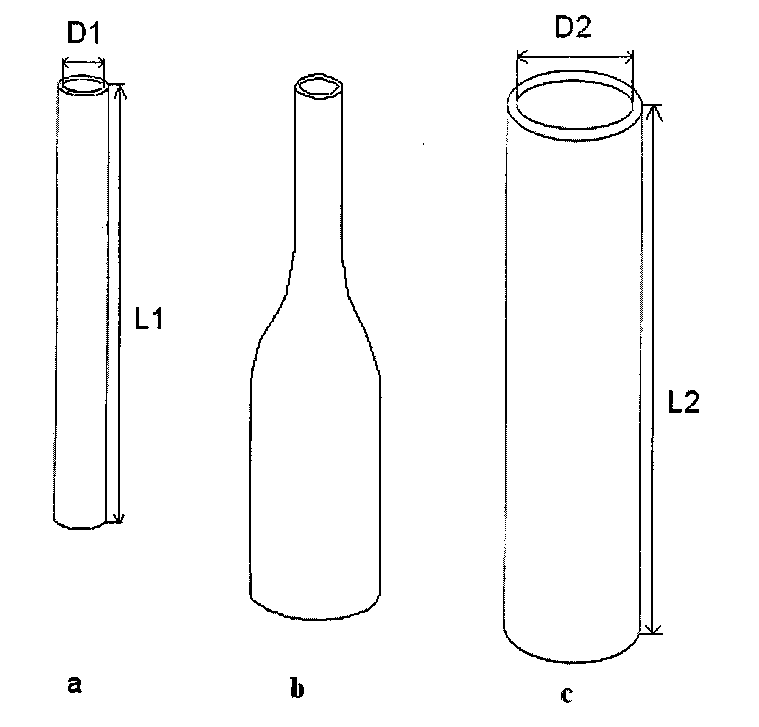

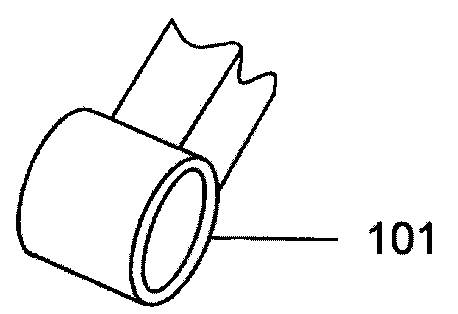

[0050] refer to image 3 , Figure 4 and Figure 5 , polymer pipe 201 (L-PLA, molecular weight is 40W~50W, the weight percentage ratio of L-PLA type polylactic acid monomer is 80%, crystallinity is 15%, pipe inner diameter is 0.50mm, wall thickness 1.50 mm) is placed in the heat transfer mold 102, the heating mold 101 moves axially at a speed of 0.5mm / s, the preheating temperature is 85°C, and the preheating is performed for 30 seconds; after the preheating is completed, keep the preheating temperature unchanged, and the mechanical core The shaft 103 precesses at a forward speed of 0.5 mm / s and a rotational speed of 10 degrees / s, and controls the size of the polymer pipe 201 through the outer diameter of the mechanical mandrel 103 and the inner diameter of the heat transfer mold 102, so that the radial expansion rate RE is 550%; while the mechanical mandrel 103 is screwing in, the polymer pipe 201 is axially stretched at a speed of 0.5mm / sec, so that the axial stretch rate A...

Embodiment 2

[0052] refer to image 3 , Figure 4 and Figure 5 , the polymer pipe 201 (L-PLA, molecular weight is 30W~40W, the weight percentage ratio of L-PLA type polylactic acid monomer is 90%, crystallinity is 20%, pipe inner diameter is 0.5mm, wall thickness 0.1 mm) is placed in the heat transfer mold 102, the heating mold 101 moves axially at a speed of 1mm / s, the preheating temperature is 80°C, and the preheating is for 20 seconds; after the preheating is completed, keep the preheating temperature unchanged, and the mechanical core The shaft 103 precesses at a forward speed of 1 mm / s and a rotational speed of 10 degrees / s, and controls the size of the polymer pipe 201 through the outer diameter of the mechanical mandrel 103 and the inner diameter of the heat transfer mold 102, so that the radial expansion rate RE is 600 %; while the mechanical mandrel 103 is screwing in, stretch the polymer pipe 201 axially at a speed of 1.5mm / sec, so that the axial stretch rate AE is 300%; after...

Embodiment 3

[0054] refer to image 3 , Figure 4 and Figure 5 , polymer pipe 201 (L-PLA, molecular weight is 40W~50W, the weight percentage ratio of L-PLA type polylactic acid monomer is 90%, crystallinity is 5%, pipe inner diameter is 0.55mm, wall thickness 2mm ) is placed in the heat transfer mold 102, the heating mold 101 moves axially at a speed of 0.2mm / s, the preheating temperature is 90°C, and the preheating mold is 30 seconds; after the preheating is completed, keep the preheating temperature unchanged, and the mechanical core The shaft 103 precesses at a forward speed of 0.2 mm / s and a rotational speed of 10 degrees / s, and controls the size of the polymer pipe 201 through the outer diameter of the mechanical mandrel 103 and the inner diameter of the heat transfer mold 102, so that the radial expansion rate RE is 580%; while the mechanical mandrel 103 is screwing in, the polymer pipe 201 is axially stretched at a speed of 1.0mm / sec, so that the axial stretch rate AE is 270%; af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com