Environment-friendly composite material for sphygmomanometers

A technology of composite materials and sphygmomanometers, applied in the field of composite materials, can solve problems such as heavy metal and phthalate pollution, separation of fluffy layer and reinforcing material layer, and affecting the service life of the cuff, and achieve broad market prospects , Improve the effect of peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings, but it is not intended to limit the protection scope of the present invention.

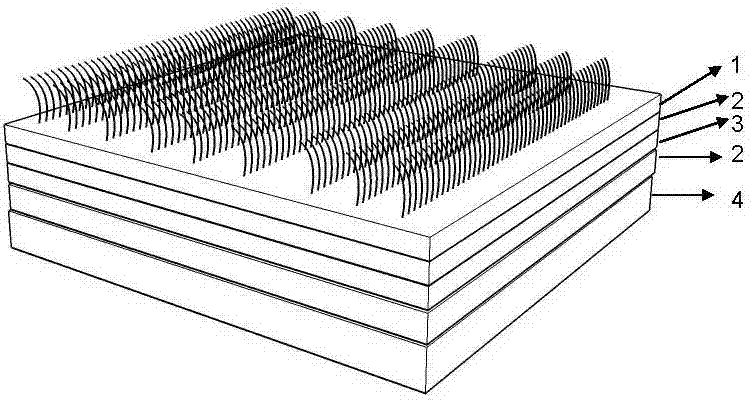

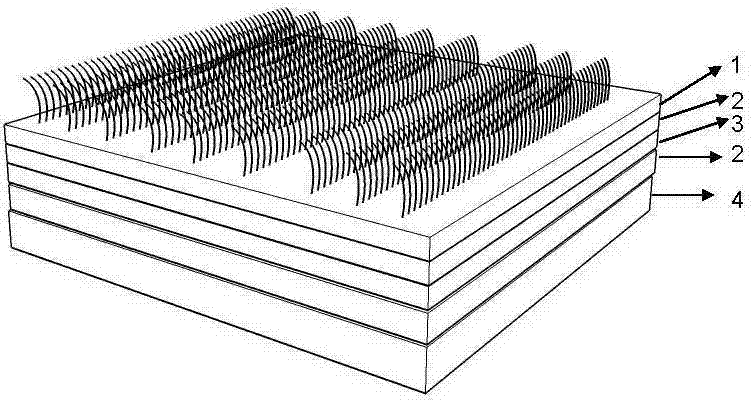

[0021] Such as figure 1 As shown, an environmentally friendly composite material for a sphygmomanometer is prepared by the following method:

[0022] (1) Using high-strength and low-shrinkage polyester yarn as raw material, the base fabric is obtained as the skeleton material after warping, weaving and splitting;

[0023] (2) Immerse the frame material in PU paste, control the thickness of 2~5 filaments by scraping, dry at 165°C~175°C, pre-dry the PVC film to 150°C~160°C, and then paste PVC on one surface of the frame material membrane;

[0024] (3) Apply a layer of PU paste on the surface of the non-woven fabric, dry it at 145°C to 155°C, heat-melt lamination, embossing, cooling and shaping, edge trimming, and coiling. The resulting composite structure is as figure 1 As shown,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com