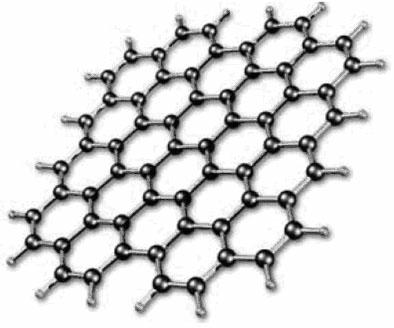

Electrically-induced reduction method for degraded graphene oxide

A graphene oxide, electric induction technology, applied in the reduction of graphene oxide, preparation and nano-etched graphene field, can solve the problem of zero band gap characteristic barrier and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

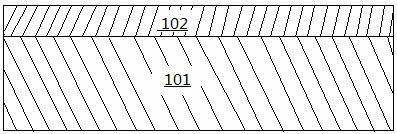

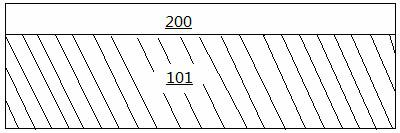

[0018] The method of using a conductive atomic force microscope to electrically induce the reduction of graphene oxide proposed by the present invention is relatively stable and reliable, and can be used as a conventional means to complete the reduction of graphene oxide. Described below is an embodiment of using a conductive atomic force microscope to electrically induce the reduction of graphene oxide proposed by the present invention.

[0019] In the drawings, for the convenience of illustration, the size of lines and structures does not represent the actual size. Although these diagrams do not completely and accurately reflect the actual scale of the instrument and circuit, they still completely reflect the general working principle of the instrument and the basic structure of the working circuit during the reduction process.

[0020] Firstly, the cleaned silicon substrate 101 is doped to form a highly doped substrate. Among them, the doping method is ion implantation, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com